Tap water hardness softening and wastewater recycling system

A tap water and wastewater technology, applied in descaling and water softening, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problem of maintenance and repair affecting the normal production of the frame, affecting the working efficiency of the cooling tower, and increasing the workshop consumables. proportion and other issues, to achieve the effect of improving the use effect of equipment, reducing cleaning steps and cleaning costs, and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

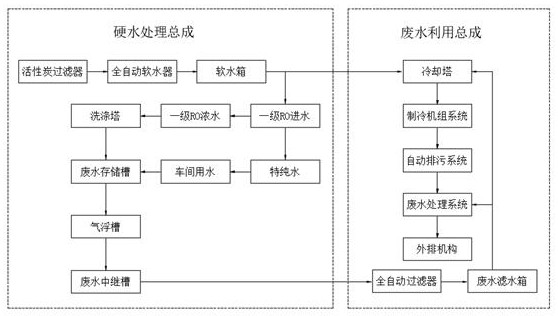

[0020] Such as figure 1 As shown, a tap water hardness softening and waste water reuse system proposed by the present invention includes a hard water treatment assembly and a waste water utilization assembly. The hard water treatment assembly includes an activated carbon filter, and the output end of the activated carbon filter is connected to a fully automatic water softener. , the output end of the automatic water softener is provided with a soft water tank, the output end of the soft water tank is provided with a washing tower, the output end of the washing tower is connected to a waste water storage tank, the output end of the waste water storage tank is connected to an air flotation tank, and the air flotation tank The output end is connected to a waste water relay tank;

[0021] The wastewater utilization assembly includes a cooling tower. The output of the cooling tower is connected to the refrigeration unit system. A waste water filter tank is connected, the input end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com