Emulsified anti-rust composition as well as preparation method and application thereof

The technology of a combination agent and an emulsion stabilizer is applied in the field of emulsification and antirust combination agent and its preparation. The effect of good stability, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

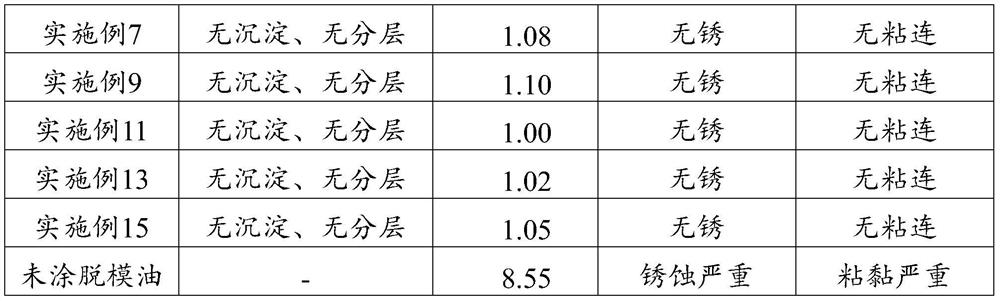

Examples

Embodiment 1

[0021] The emulsified antirust composition of this embodiment comprises the following components in parts by mass: 80% naphthenic acid, 17% alkali, 1.5% sorbitan monooleate and 1.5% emulsion stabilizer;

[0022] Among them, the acid value of naphthenic acid is 175-270mgKOH / g, the content of inorganic salt is not more than 1wt.%, and the chloride is not more than 0.3wt.%.

[0023] The base is sodium hydroxide;

[0024] Emulsion stabilizer is triethanolamine.

[0025] The preparation method of the emulsified antirust composition of this embodiment comprises the following steps: react naphthenic acid and alkali at 40°C for 0.5h to obtain sodium naphthenate and water, continue to add emulsified antirust agent and emulsified stabilizer, and stir for 1h Afterwards, the antirust composition is obtained.

Embodiment 2

[0027] The emulsified mold release oil of this embodiment includes the following components in terms of mass percentage: 70% of the second-line extraction oil, 6% of the emulsified antirust composition prepared in Example 1, and 24% of water.

[0028] The preparation method of the emulsified release oil of this embodiment includes the following steps: after heating the oil extracted from the second line to 50-60°C, add the emulsified anti-rust composition and water, stir for 1 hour, cool and filter to obtain the emulsified release oil Oil.

Embodiment 3

[0030] The emulsified release oil of this embodiment comprises the following components in terms of mass percentage: 73% of the second-line extraction oil, 6% of the emulsified anti-rust composition prepared in Example 1 and 21% of water.

[0031] The preparation method of the emulsified release oil of the present embodiment is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com