Acid pickling and tin injection device for lamp holder connection points

A lamp head connection and tin injection technology, applied in auxiliary devices, welding equipment, electrical components, etc., can solve the problems of easy oxidation of the conical shell, affect the conductivity, and easy dripping of solder, so as to avoid short circuits and enhance conductivity. , the effect of reducing resistance and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

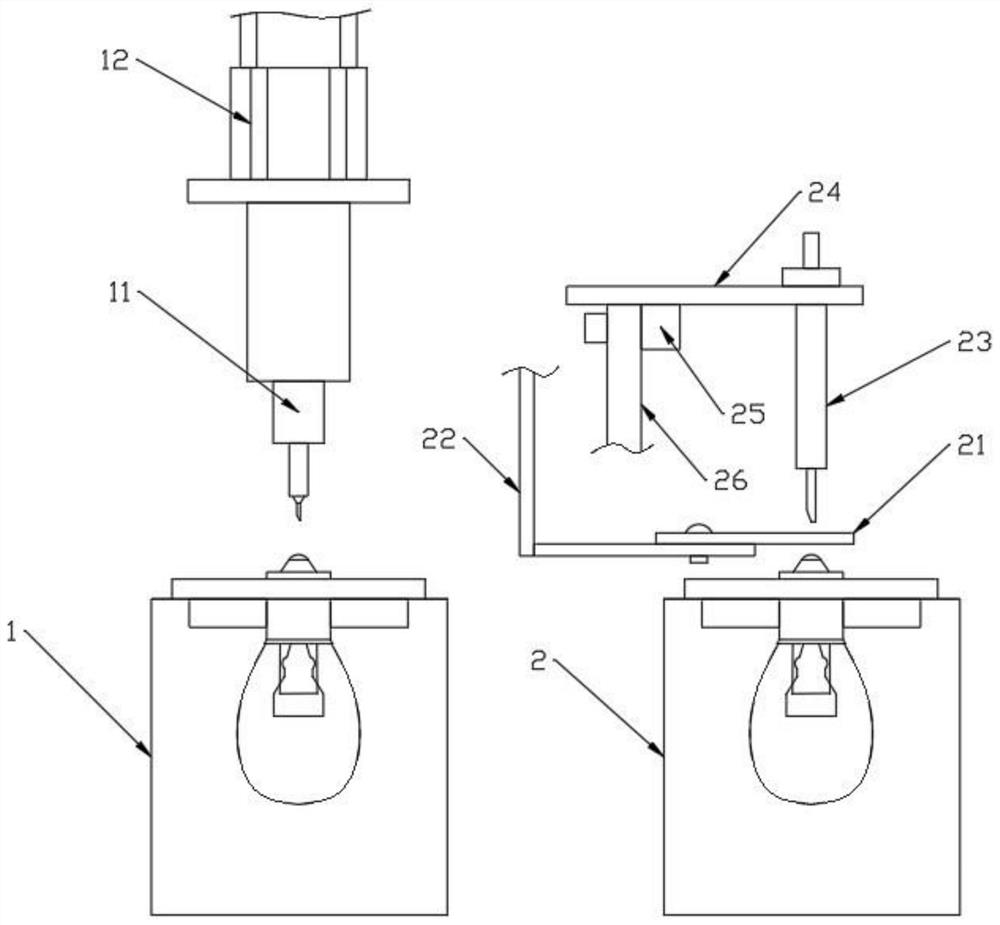

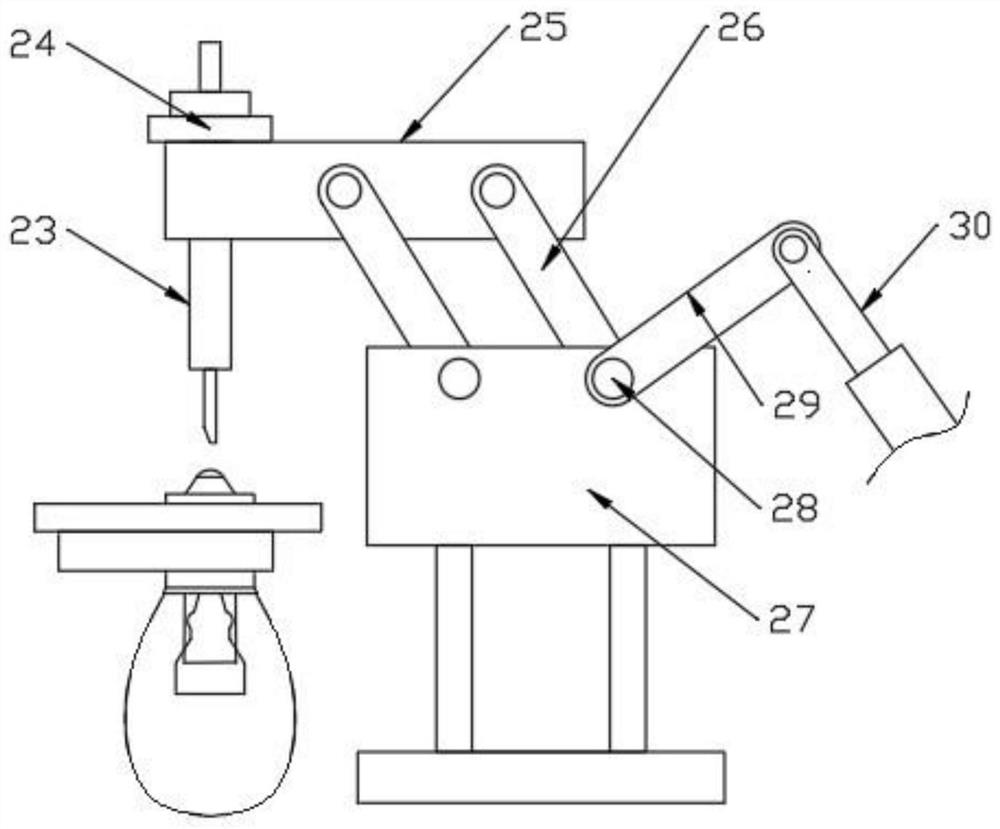

[0018] like Figure 1~2 As shown, a pickling and tin injection device for the connection point of the lamp cap includes a pickling station 1, an acid injection dropper 11, a first lifting device 12, a tin injection station 2, a blocking piece 21, a connecting arm 22, Tin-filling type electric iron 23, connecting plate 24, upper connecting seat 25, rotating arm 26, lower connecting seat 27, rotating shaft 28, connecting rod 29 and telescopic arm 30.

[0019] A pickling and tin injection device for the connection point of the lamp cap, comprising a pickling station 1 and a tin injection station 2, the pickling station 1 and the tin injection statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com