Graphene laminated board as well as preparation method and application thereof

A graphene layer and graphene technology, applied in the field of graphene, can solve the problems of high operating energy requirements, difficult to meet large-scale production, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the graphene laminate comprises the step of annealing at 1000° C., and the step of applying mechanical compression at 150° C. and 5 MPa to the graphene foil to obtain the graphene laminate, and the annealing and mechanical compression are carried out simultaneously.

[0031] Wherein, the specific operation of the mechanical compression is to place a pair of ultra-smooth stainless steel plates on both sides of the graphene foil, and apply a pressure of 5 MPa in an environment of 150°C.

[0032] Further, the graphene foil is prepared by printing graphene slurry on a carrier plate.

[0033] The carrier plate can be glass slide or aluminum foil, and can also be one of PET, PI, PC and other polymer substrates.

[0034] Wherein, when a glass slide is selected as the carrier plate, isopropanol should be used to clean its surface; preferably, the thickness of the aluminum foil is 18-80 μm.

[0035] Further, the graphene slurry is a water-based graphen...

Embodiment 1

[0048] The preparation method of graphene laminate comprises the steps:

[0049] S1. Use an automatic template printer (DEK Horizon n03iX) to print the graphene slurry on the surface of an aluminum foil with a thickness of 20 μm, the printing thickness is 3 to 5 mm, and dry it in a hot air oven at 150 ° C for 5 hours. Graphene film is formed on the surface of aluminum foil;

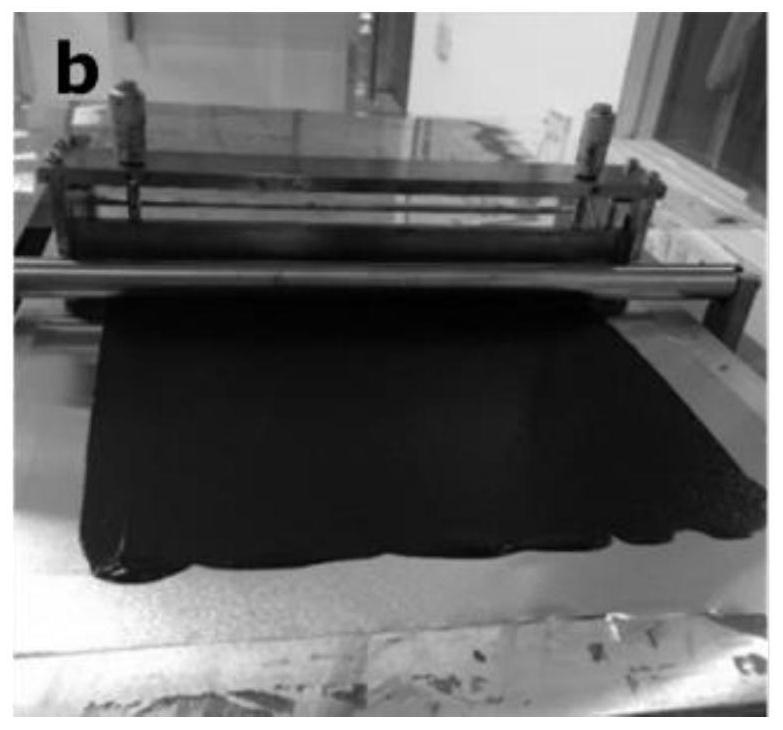

[0050] S2, immersing the graphene film in water to release the graphene film from the surface of the aluminum foil, and utilizing a semi-automatic blade coater (MTI company) to prepare a graphene foil of a larger size (at least 125mm * 200mm) with the released graphene film, and Air-dry the graphene foil for 3 hours at a wind speed of 10km / h;

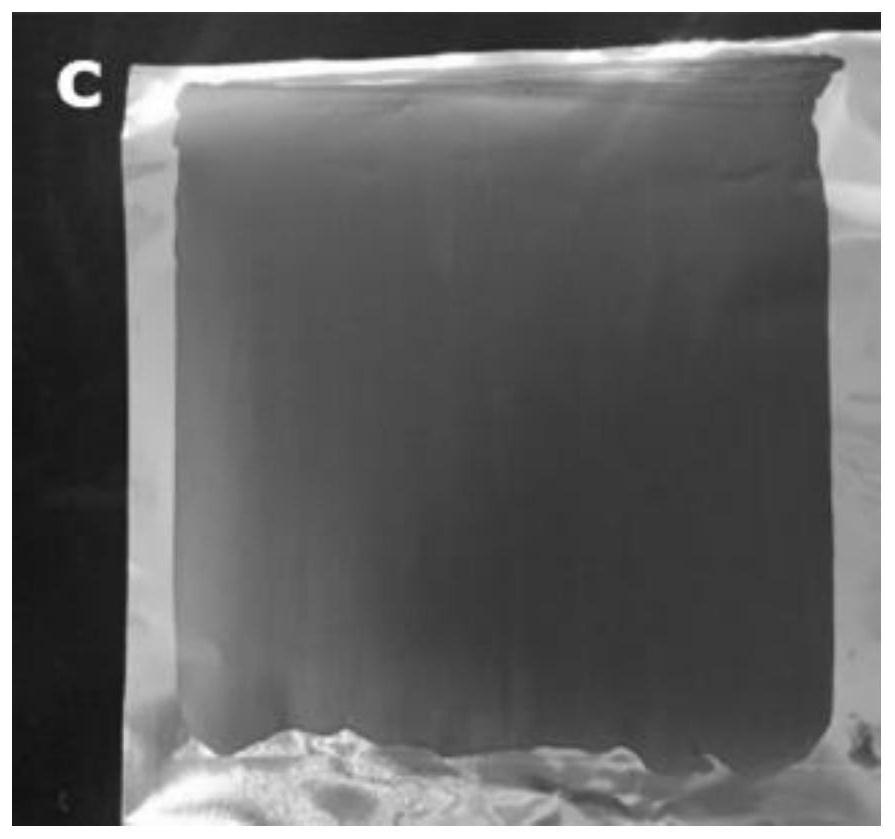

[0051] S3. Place the air-dried graphene foil between a pair of smooth stainless steel plates. In a tube furnace, under a nitrogen atmosphere, anneal the graphene foil at 1000°C at a heating rate of 3°C / min. ℃, 5MPa mechanical compression (press, Caver Company), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com