Method for modifying opened fiber reinforced regenerated artificial stone by using waste textiles

A waste textile and fiber reinforcement technology, used in textiles and papermaking, fiber cleaning, fiber processing, etc., can solve environmental problems of waste textiles and other problems, and achieve the effect of improving compatibility, improving hydrophobicity, and saving enterprise costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

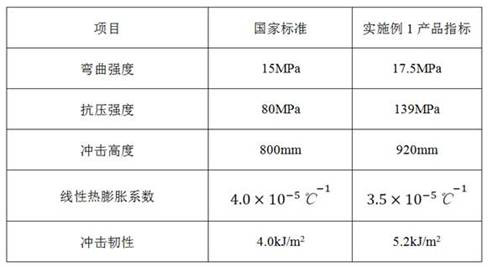

Embodiment 1

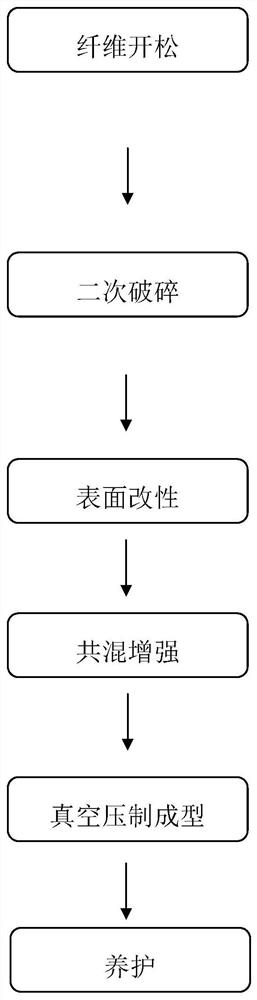

[0041] A method for reinforcing regenerated artificial stone using modified opening fibers of waste textiles, characterized in that it comprises the following steps:

[0042] Step 1: Fiber opening: The waste textile scraps recovered from the textile workshop of Fujian Baichuan Resources Recycling Technology Co., Ltd. and the fiber waste silk recovered from the spinning workshop are opened by opening equipment, and the fiber length after opening is 15-20cm ;

[0043] Step 2: secondary crushing: use a blade crusher to perform secondary crushing on the opened fibers obtained in step 1; the fiber length after being crushed by the blade crusher is 2 to 4 cm;

[0044] Step 3: Surface modification: Soak the loosened and broken fibers obtained in Step 2 in ethanol / water solution containing silane coupling agent (see the formula below), heat to a predetermined temperature for a period of time, and dry;

[0045] Solution formulation for surface treatment of fibers:

[0046]Ethanol / wat...

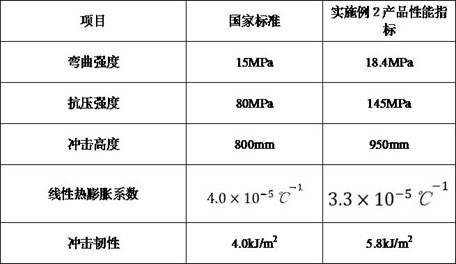

Embodiment 2

[0057] A method for reinforcing regenerated artificial stone using modified opening fibers of waste textiles, characterized in that it comprises the following steps:

[0058] Step 1: Fiber opening: The waste textile scraps recycled by Jinjiang Huafeng Shoes and Clothing Company are opened by opening equipment, and the length of the fiber (opened fiber) after opening is 15-20cm;

[0059] Step 2: secondary crushing: use a blade crusher to perform secondary crushing on the opened fibers obtained in step 1; the length of the fibers after being crushed by the blade crusher (fibers after opening and crushing) is 2 to 4 cm;

[0060] Step 3: Surface modification: Soak the loosened and broken fibers obtained in Step 2 in ethanol / water solution containing silane coupling agent (see the formula below), heat to a predetermined temperature for a period of time, and dry;

[0061] Solution formulation for surface treatment of fibers:

[0062] Ethanol / water solution containing silane couplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com