Porous graphene powder as well as preparation method and application thereof

A porous graphene and powder technology, applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of uncontrollable pore size, and achieve simple preparation method and good process stability , the effect of good magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

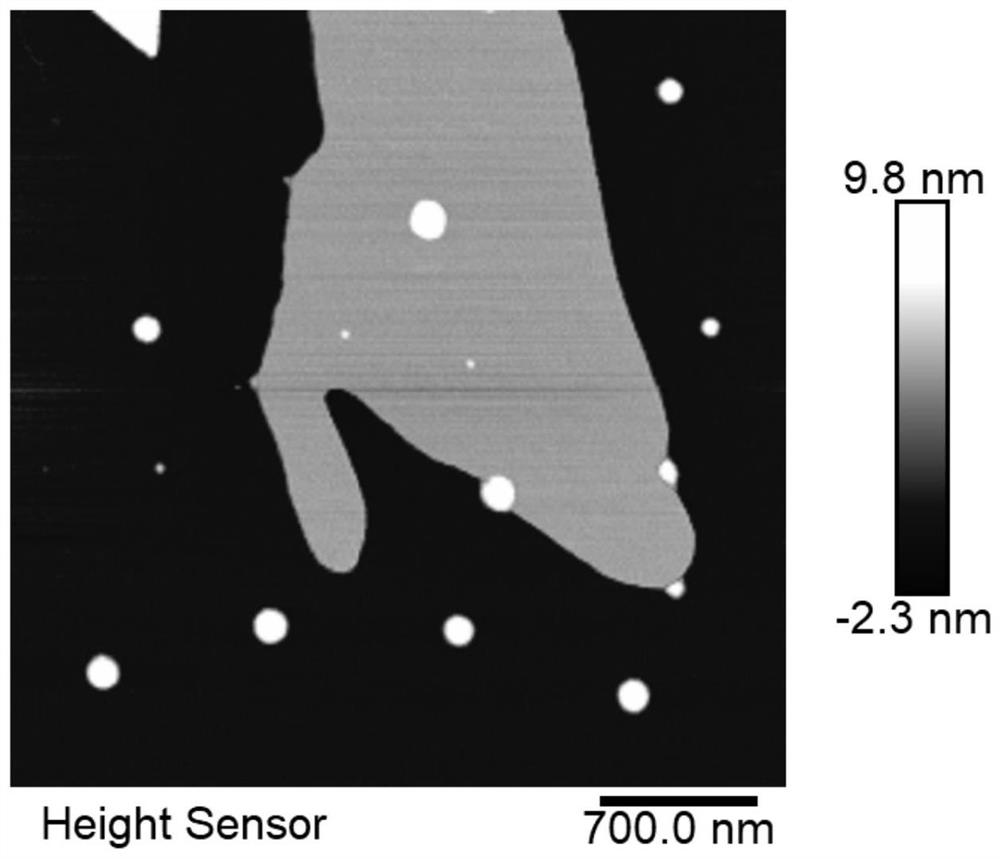

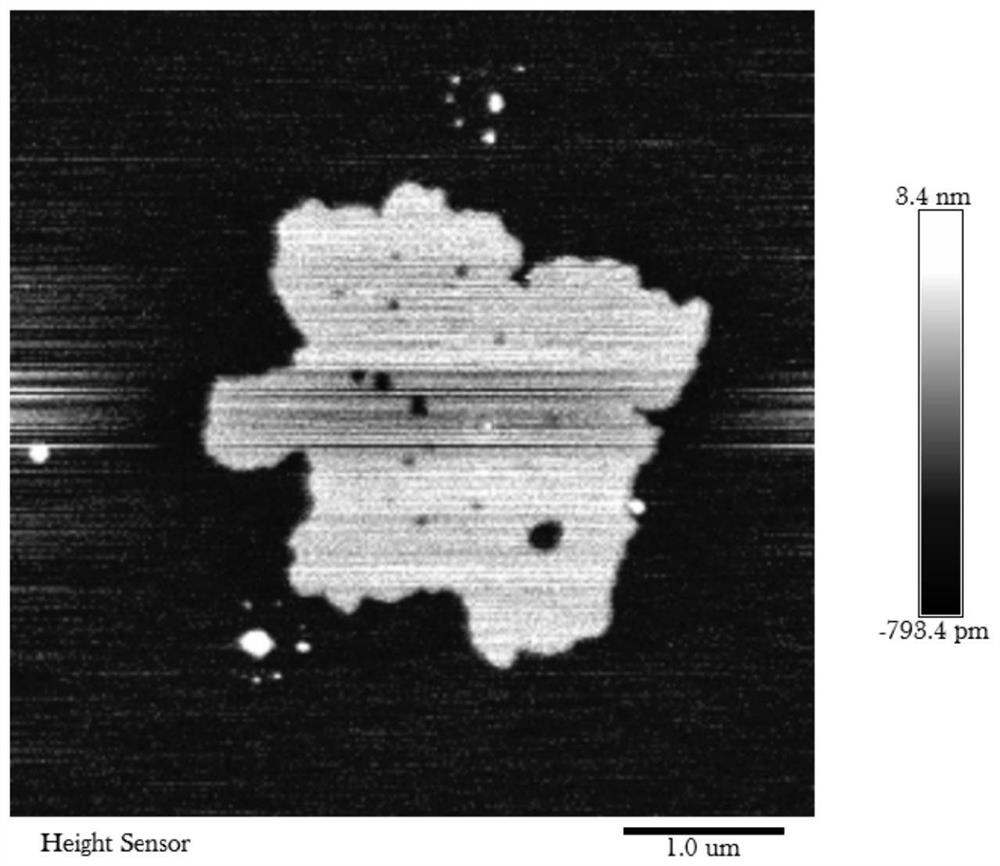

Image

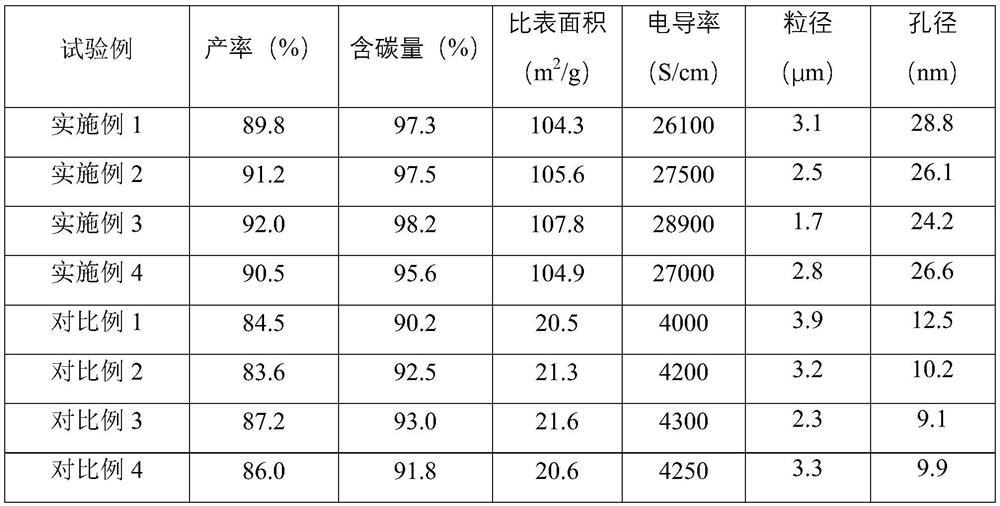

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of porous graphene powder, comprises the following steps:

[0031] S1. Dissolve the expanded graphite in deionized water, stir in the reaction kettle evenly to obtain a dispersion;

[0032] Among them, the D50 of expanded graphite is 40-100μm, and the specific surface area is 30-50m 2 / g, the bulk density is 0.02-0.04g / cm 3 , the magnetic foreign matter is less than 1000ppb, the stirring speed of the reactor is 80-100r / min, the rotating speed of the dispersing plate of the reactor is 1200-1500r / min, stirring and dispersing for 1-2h, the content of expanded graphite is 1-2.5wt of the mixed solution %;

[0033] S2. The dispersion liquid obtained in step S1 is sent into the micro-jet equipment for processing through the diaphragm pump, the flow rate of the diaphragm pump is 20-30 / min, the micro-jet pressure is 1000-1200MPa, and the above steps are repeated 3-5 times;

Embodiment 1

[0042] The invention provides a kind of preparation method of porous graphene powder, comprises the following steps:

[0043] S1. Dissolve the expanded graphite in deionized water, stir in the reaction kettle evenly to obtain a dispersion;

[0044] Among them, the D50 of expanded graphite is 40μm, and the specific surface area is 30m 2 / g, bulk density is 0.04g / cm 3 , the magnetic foreign matter is less than 800ppb, the stirring speed of the reactor is 80r / min, the rotating speed of the dispersing plate of the reactor is 1500r / min, stirring and dispersing for 1h, the content of expanded graphite is 1wt% of the mixed solution;

[0045]S2. The dispersion liquid obtained in step S1 is sent into the micro-jet equipment for processing through the diaphragm pump, the flow rate of the diaphragm pump is 20 / min, the micro-jet pressure is 1000MPa, and the above-mentioned steps are repeated 3 times;

[0046] S3. Freeze-drying the solution obtained in step S2 to prepare a powder;

[00...

Embodiment 2

[0051] Specifically with embodiment 1, the difference is:

[0052] In this example, in step S1, the D50 of expanded graphite is 100 μm, and the specific surface area is 35 m 2 / g, bulk density is 0.02g / cm 3 , the magnetic foreign matter is less than 700ppb, the stirring speed of the reactor is 85r / min, the rotating speed of the dispersing plate of the reactor is 1200r / min, stirring and dispersing for 2h, the content of expanded graphite is 1.5wt% of the mixed solution;

[0053] In step S2, the flow rate of the diaphragm pump is 25 / min, the microjet pressure is 1200MPa, and the above steps are repeated 4 times;

[0054] In step S4, the activation temperature is 1100° C. for 5 hours at a constant temperature, and the amount of carbon dioxide introduced is 2.5 L / min;

[0055] In step S5, the activation temperature is 1100° C. for 5 hours at a constant temperature, and the amount of water vapor introduced is 2.5 L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com