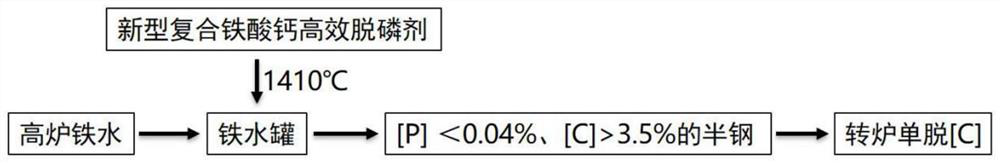

A steelmaking method of ladle dephosphorization-converter single decarburization

A molten iron tank and dephosphorization technology, applied in the field of metallurgy, can solve problems such as steelmaking processes that have not yet been discovered, and achieve the effects of shortening converter smelting time and high purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

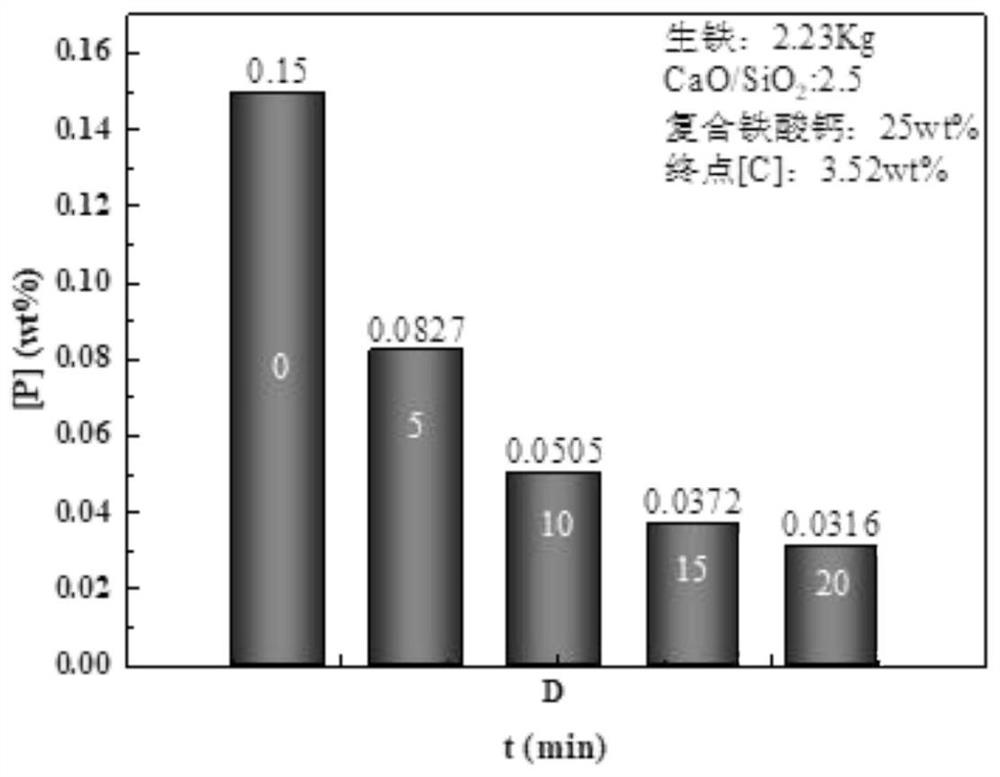

[0042] Take 2.23kg of pig iron with an initial [P] content of 0.15wt% for dephosphorization test, control the temperature at 1410°C, add 97g of iron oxide scale, 23g of lime and 40g of composite calcium ferrite into the furnace, and carry out dephosphorization for 15min to obtain half steel;

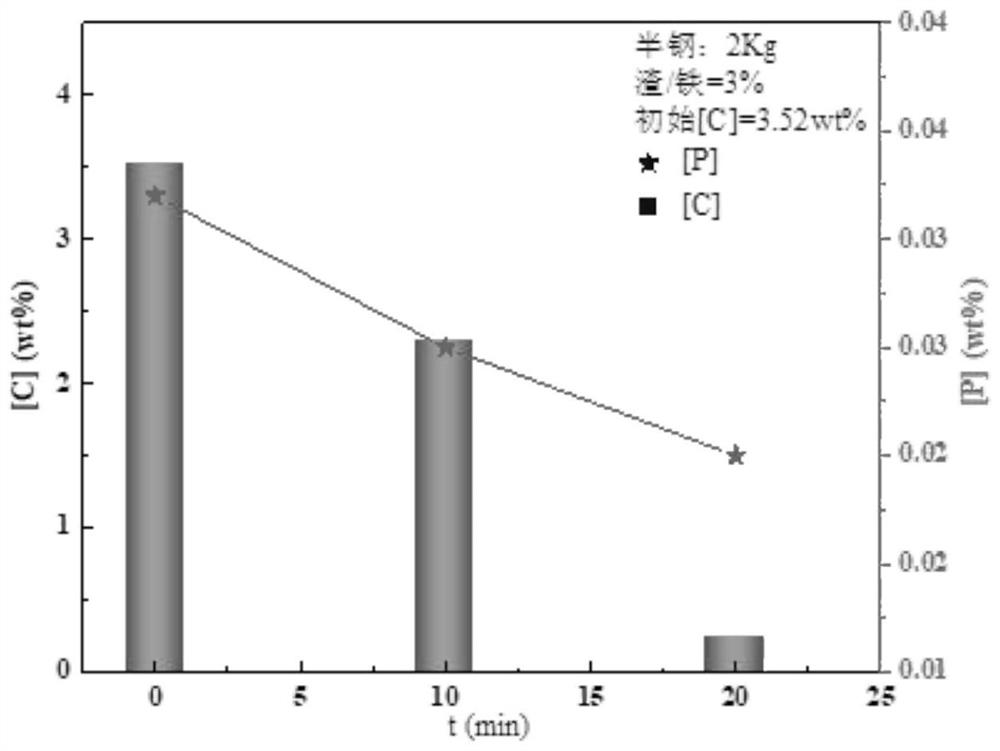

[0043] 2kg of the semi-steel was subjected to a single decarburization test, the blowing initial temperature was 1350°C, 35g of slagging agent lime and 25g of red mud were added to the furnace in batches, and after the slagging agent was completely melted, oxygen blowing was started, and the flow rate was controlled at 0.7m 3 / h, after decarburization for 20min, molten steel is obtained.

Embodiment 2

[0045] It is basically the same as Example 1, except that the dephosphorization time is adjusted from "15min" to "20min".

Embodiment 3

[0047] It is basically the same as Example 1, except that the dephosphorization time is adjusted from "15min" to "10min".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com