Electric welding head of pinpoint welding

A welding head, parallel electrode technology, used in resistance welding equipment, circuits, welding media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

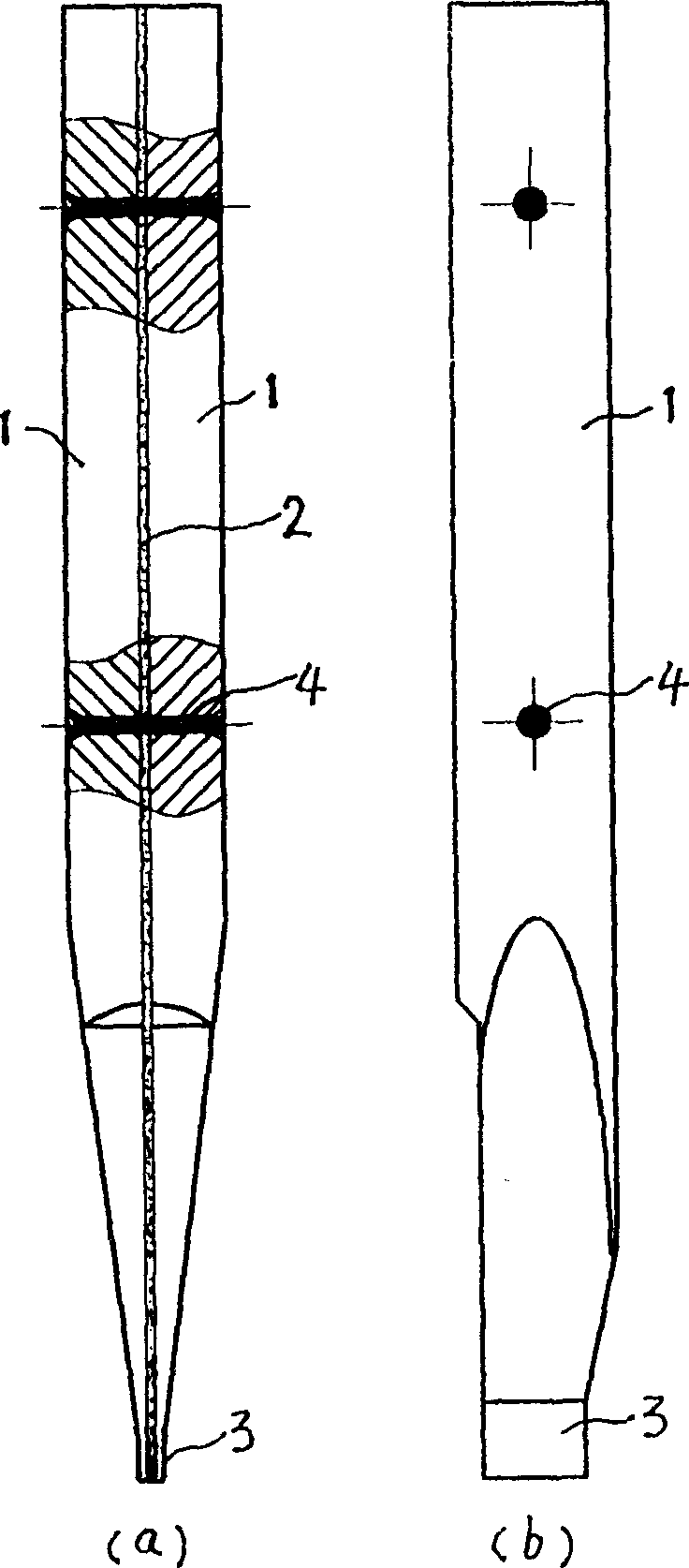

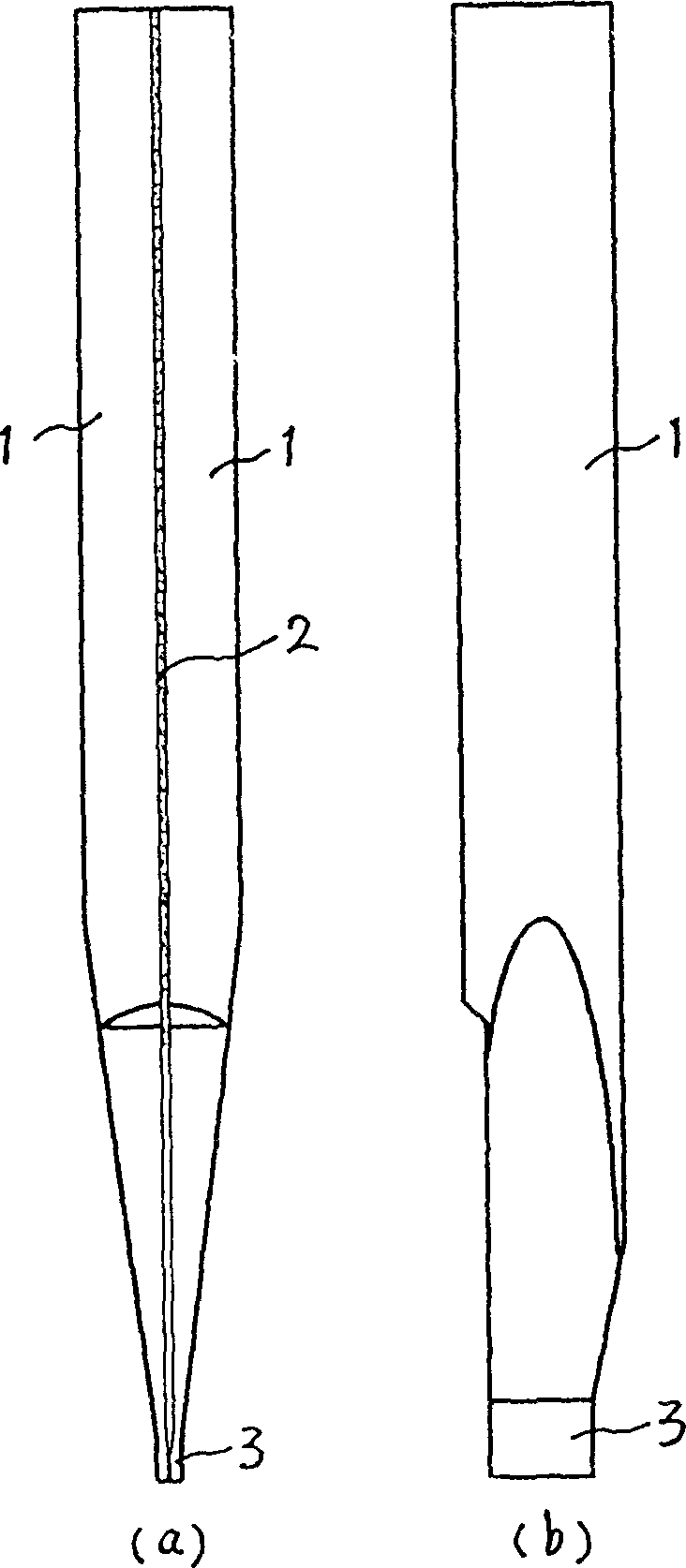

[0013] figure 2 Middle: 1 is the two parallel electrodes of the welding head, which are made of high temperature resistant metal materials (such as tungsten, molybdenum and their alloys, etc.). 2 is an insulating layer, which is bonded by thermosetting insulating adhesive, and the insulation separation gap can be between 0.02-0.15mm. 3 is the tip part of the welding head, the tips of the two electrodes are slightly bent inward, forming ohmic contact with each other, the contact resistance is generally ≤200mΩ, and the rest are separated by insulation layer 2; the tip part 3 of the welding head can also be made Like the existing welding head, the two parallel electrodes are completely insulated and separated by the insulating layer 2 .

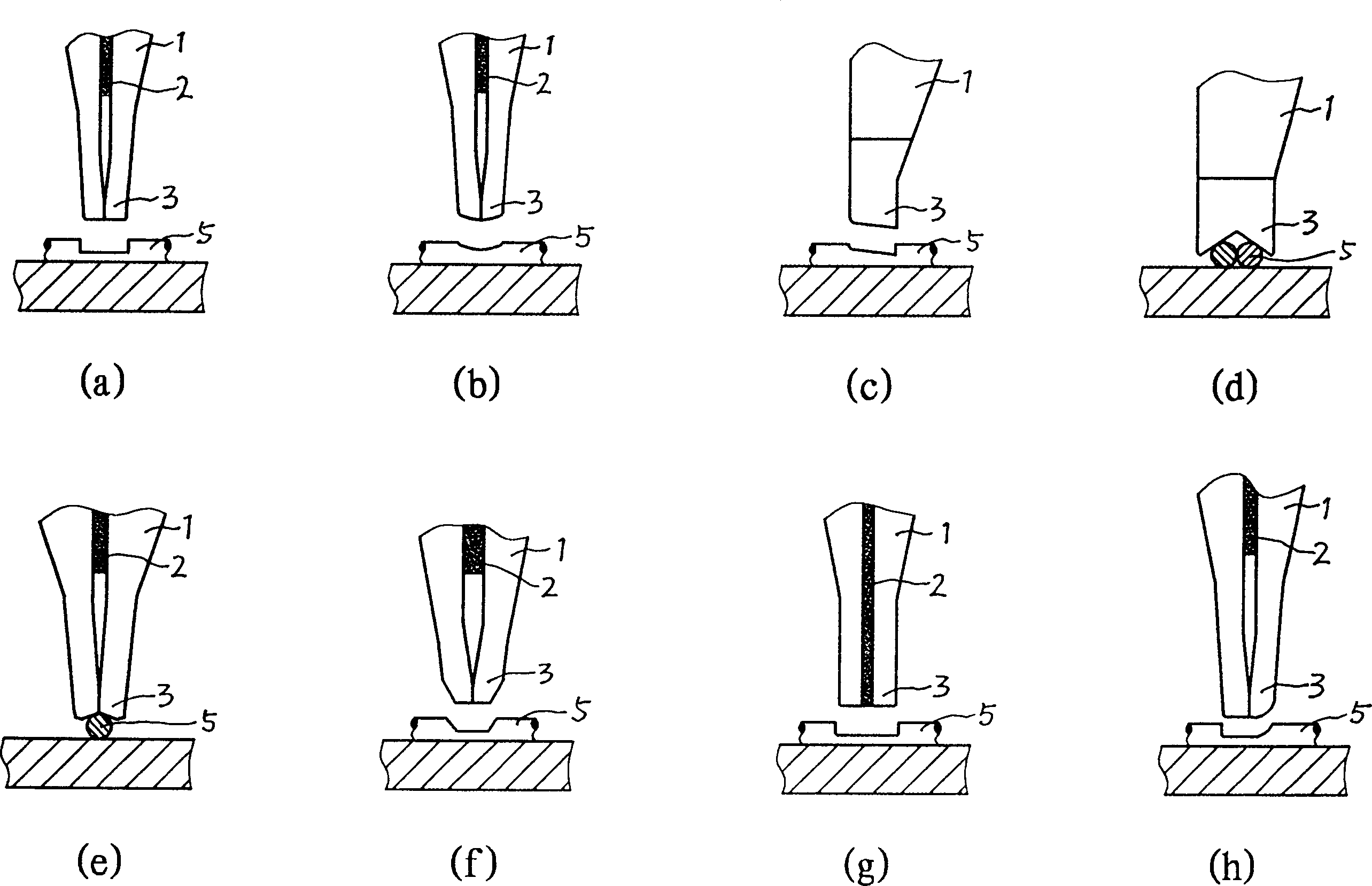

[0014] image 3 Middle: (a) is a welding head with a planar structure at the tip end surface. The tip parts of the two parallel electrodes are made to be in ohmic contact with each other, and the shape of the tip end surface is made into a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com