SMT production line connection table width adjustment control method and device, equipment and storage medium

A control method and a technology of a control device, which are applied in the fields of printed circuit manufacturing, printed circuit assembly of electrical components, image data processing, etc., can solve the problems of fewer operators, losses, and production accidents in the production line, so as to avoid accidents and avoid production failures. Accidents, ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

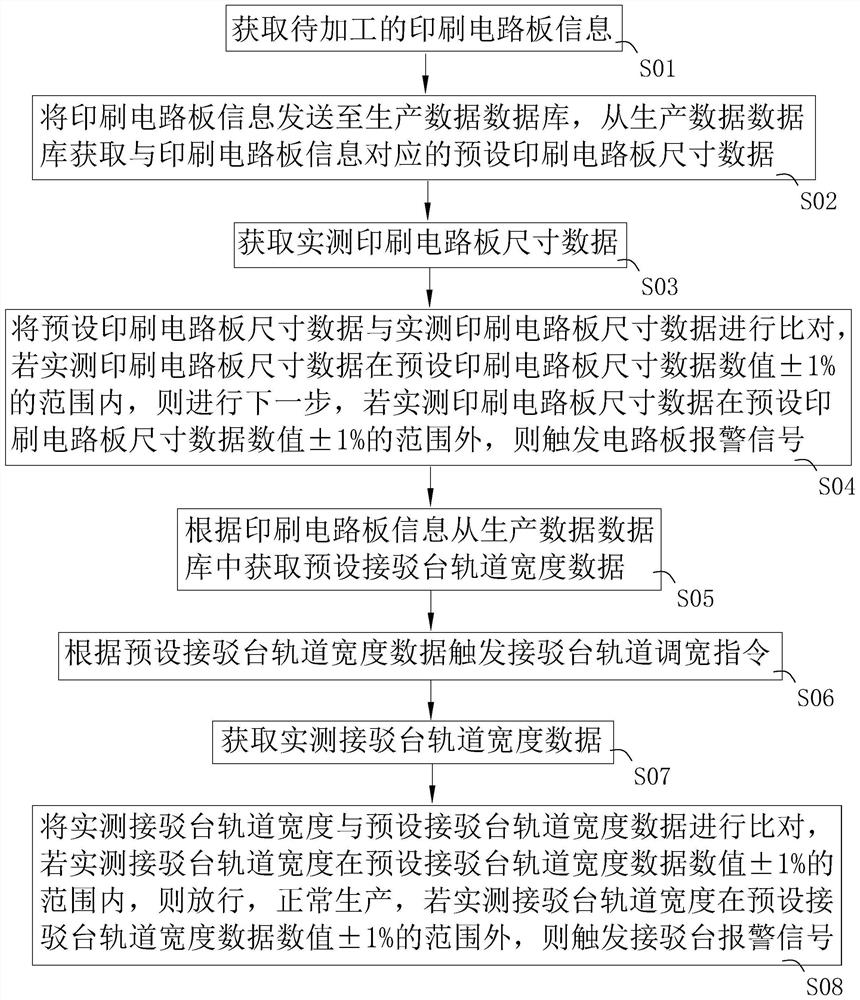

[0071] A method for controlling the width adjustment of a connecting table in an SMT production line, referring to Figure 1-3 .

[0072] Include the following steps:

[0073] S01. Obtain the information of the printed circuit board to be processed.

[0074] In this embodiment, the printed circuit boards are printed with barcodes, and the printed circuit board information is stored in the barcodes, and the printed circuit board information includes the type of the printed circuit board.

[0075] Specifically, a code scanning device is provided on the previous machine of each docking station. When the printed circuit board passes through the code scanning device, the printed circuit board information stored in the barcode is read by the scanning device to obtain the printed circuit board information. board model.

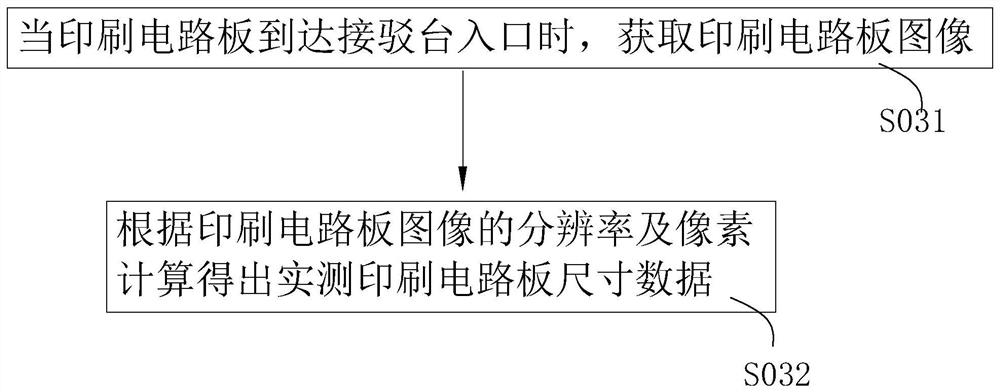

[0076] S02. Send the printed circuit board information to the production data database, and acquire preset printed circuit board size data corresponding to the pr...

Embodiment 2

[0113] A control method for adjusting the width of a connecting platform in an SMT production line. Compared with Embodiment 1, the only difference is:

[0114] S02, input the printed circuit board information into the production data database, obtain preset printed circuit board size data from the production data database, and trigger an alarm signal if the acquisition fails.

[0115] Specifically, refer to figure 1 , 4 , by inputting the printed circuit board model obtained in S01 into the production data database, according to the corresponding relationship between different printed circuit board models and the three-dimensional model of the printed circuit board in the production data database, the preset corresponding to the printed circuit board information is obtained For the printed circuit board size data, if there is no corresponding preset printed circuit board size data available, an alarm command is issued.

Embodiment 3

[0117] A control method for adjusting the width of a connecting platform in an SMT production line. Compared with Embodiment 1, the only difference is:

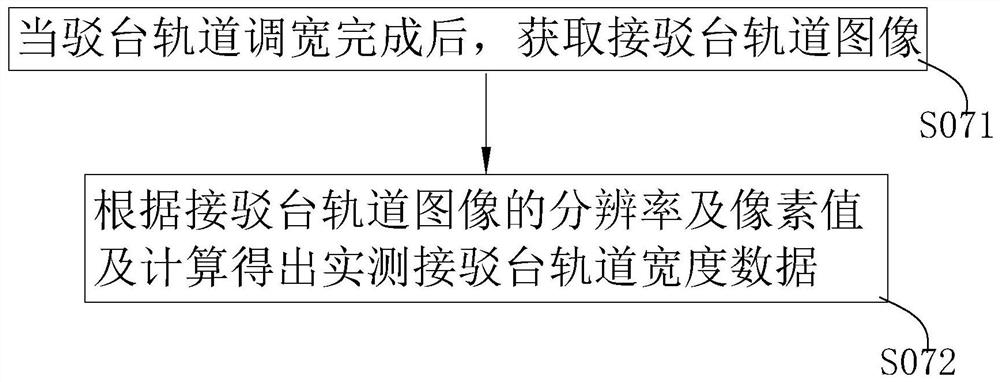

[0118] S08. Compare the measured track width of the docking station with the preset track width data of the docking station. If the measured rail width of the docking station is within the range of ±1% of the preset rail width data value of the docking station, it will be released. It is normal. For production, if the measured rail width of the docking station is outside the range of ±1% of the preset rail width data value of the docking station, the alarm signal of the docking station will be triggered, and the measured rail width of the docking station will be sent to the alarm record database, and calculated at the same time The difference between the measured rail width of the docking station and the preset rail width of the docking station is sent to the control device of the docking station. The control device adjusts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com