Composite material for improving metal conductivity and preparation method thereof

A composite material and metal conduction technology, which is applied in the direction of metal material coating process, metal layered products, chemical instruments and methods, etc., can solve the problem of reducing the electrical conductivity of materials, failing to improve electrical conductivity, and unable to form carrier channels and other issues to achieve the effect of excellent conductivity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

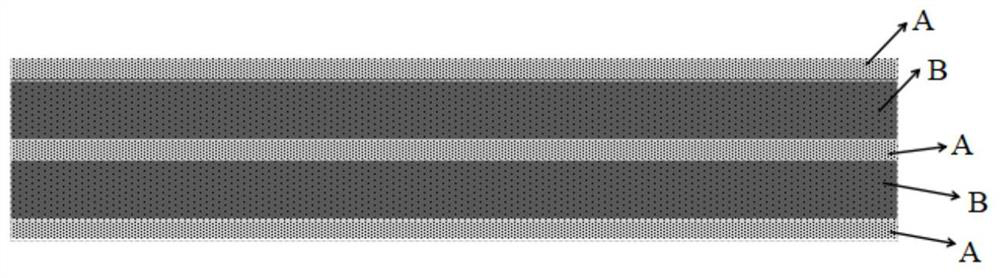

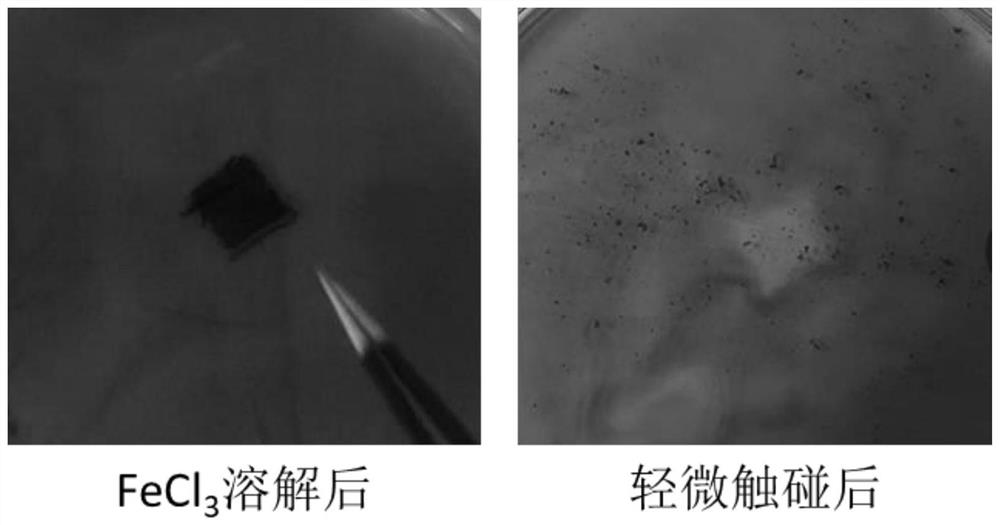

Embodiment 1

[0041]Graphene is deposited on both sides of the 30 μm thick rolled copper foil by CVD method to form continuous single-layer high-quality graphene, and the mass fraction of the graphene in the composite material is controlled to be about 0.0008%, or all The volume fraction of the graphene in the composite material is about 0.003%, and then a graphene-copper foil three-layer structure is obtained, and the graphene is uniformly fractured by stretching, and the 20-layer graphene- The copper foil is formed at a temperature of 920 ° C and a pressure of 45 MPa. The formed graphene-copper composite material is tested by the four-probe method, the conductivity is 119.84% IACS, and the tensile strength is 258 MPa. The bending test (bending test refers to each angle) All were subjected to a certain degree of bending experiment, and the following bending experiments were the same) and the conductivity was 118.91% IACS. The copper on the surface of one side of the graphene-copper composi...

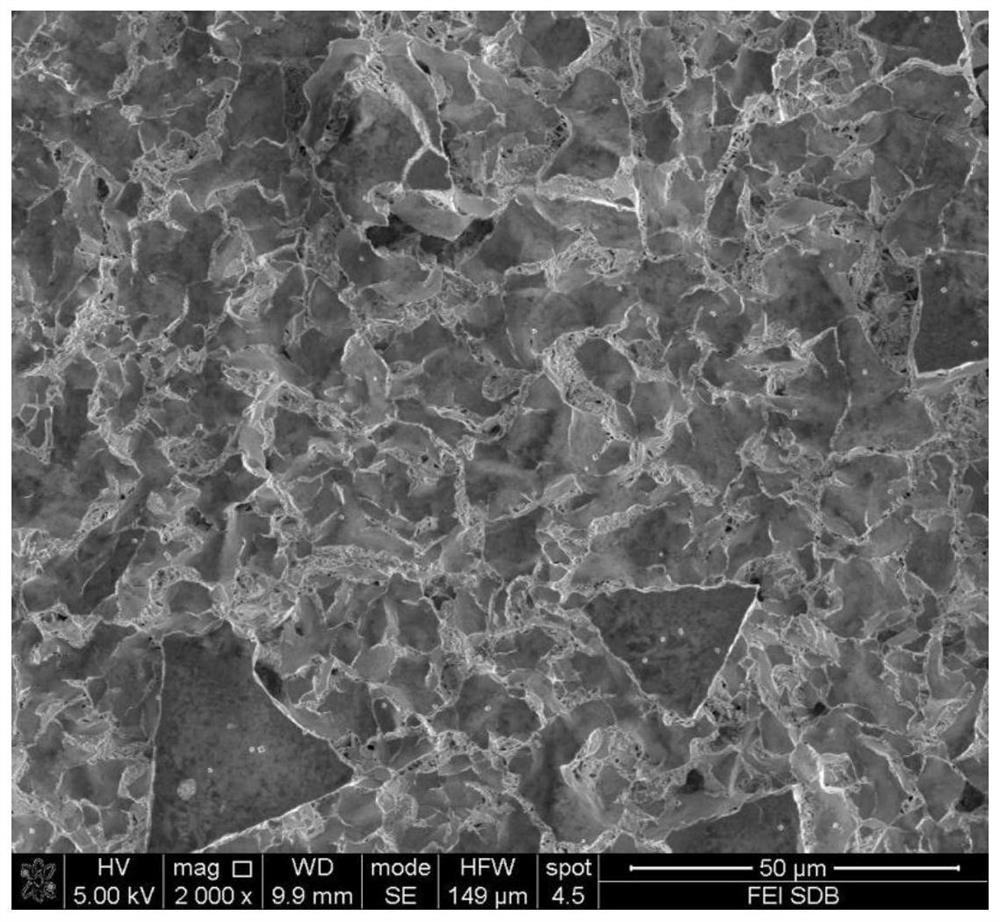

Embodiment 2

[0043] Graphene was deposited on both sides of a 40-μm-thick electrolytic aluminum foil (conductivity 59.1% IACS) by CVD to form continuous multi-layer high-quality graphene, and the mass fraction of the graphene in the composite material was controlled to about is 0.01%, or the volume fraction of the graphene in the composite material is about 0.01%, and then a graphene-aluminum foil three-layer structure is obtained. The graphene-aluminum foil was formed at a temperature of 480°C and a pressure of 15MPa. The formed graphene-aluminum composite material was tested by the four-probe method with a conductivity of 71.52% IACS, a tensile strength of 223MPa, and a conductivity of 69.98 after the bending test. %IACS. The aluminum on the surface of the graphene-aluminum composite material was etched away with an etching solution, and the graphene morphology was exposed and observed by scanning electron microscope. , the morphology is polygonal fragments, each fragment area is 50-100...

Embodiment 3

[0045] Graphene was deposited on both sides of a 20 μm thick silver foil (conductivity 107.8% IACS) by CVD method to form continuous double layers of high-quality graphene, and the mass fraction of the graphene in the composite material was controlled to be about 0.002%, or the volume fraction of the graphene in the composite material is about 0.01%, and then a graphene-silver foil three-layer structure is obtained. The graphene-silver foil was formed at a temperature of 800 °C and a pressure of 40 MPa. The formed graphene-silver composite material was tested by the four-probe method with a conductivity of 127.59% IACS, a tensile strength of 129 MPa, and a conductivity of 129 MPa after the bending test. 126.33% IACS. The silver on the surface of the graphene-silver composite material was etched away by etching solution, and the morphology of graphene was exposed and observed by scanning electron microscope. The results showed that the graphene was evenly distributed in the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com