Acid-resistant and salt-resistant glycosylated protein-rice bran polysaccharide emulsifier and preparation method thereof

A technology of glycosylated protein and rice bran polysaccharide, which is used in food ingredients as emulsifier, polysaccharide/gum-containing food ingredients, food science and other directions, can solve the problems of low comprehensive utilization rate and less than 20% utilization rate, and achieve improvement Functional properties, improved emulsifying properties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of acid-resistant and salt-resistant glycosylated rice bran polysaccharide-whey protein emulsifier, comprising the following steps:

[0032] (1) Dissolve WPI and RBP in 0.1M PBS buffer solution (pH=8.0) according to the ratio of 1:1 (w:w) to ensure that the solids content is 6%, adjust the pH of the solution to 8.0, and stir under constant temperature magnetic force Stir continuously in the container for 12h

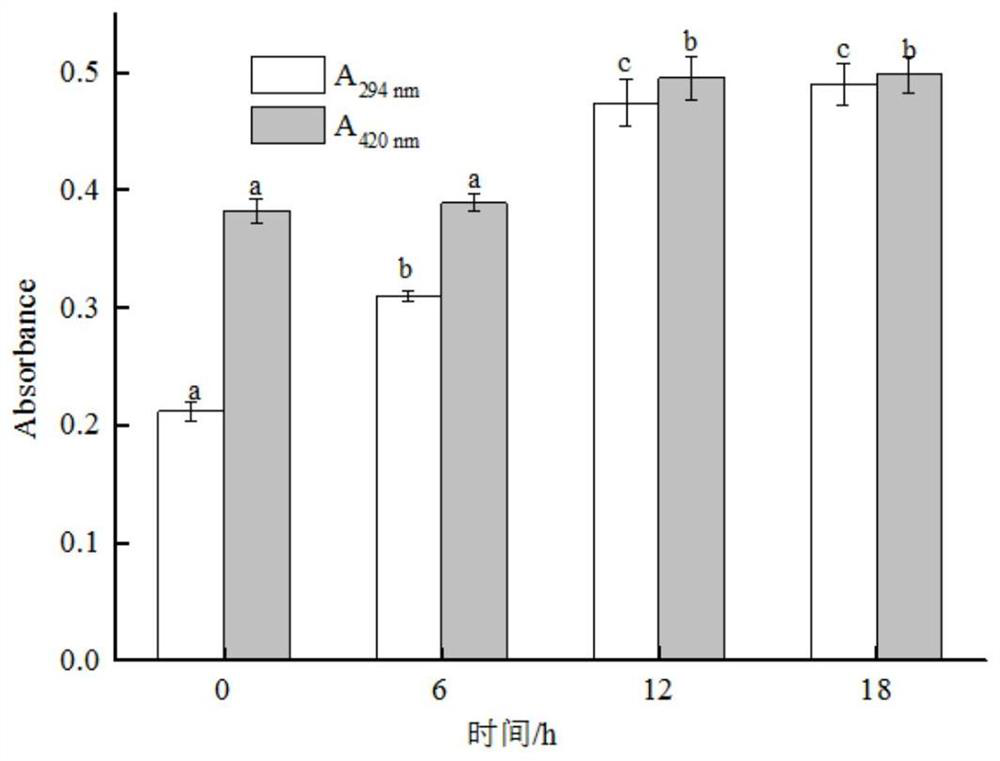

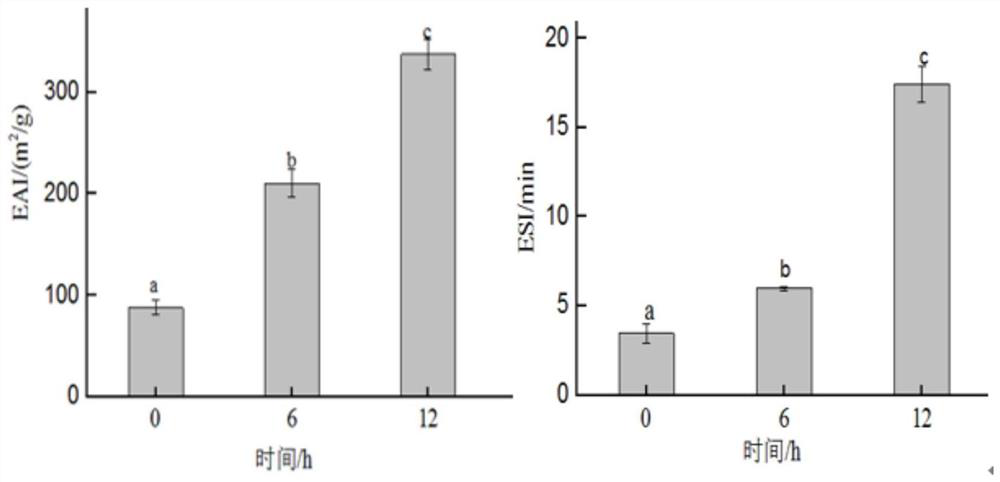

[0033] (2) The solution described in step (1) is fully mixed and freeze-dried, and the freeze-dried powder is placed in a desiccator after passing through a 100-mesh sieve (saturated KBr solution is placed at the bottom of the container), and the desiccator is placed in a blast In a drying oven, adjust the temperature to 60°C to keep the relative humidity in the dryer at 79%. After 6, 12, and 18 hours of reaction, the whey protein isolate-rice bran polysaccharide graft is obtained, and the obtained product is stored in a -20°C refrigerator.

...

Embodiment 2

[0040] A preparation method of acid-resistant and salt-resistant glycosylated rice bran polysaccharide-whey protein emulsifier, comprising the following steps:

[0041] (1) Dissolve WPI and RBP in 0.1M PBS buffer solution (pH=8.0) according to the ratio of 1:1 (w:w) to ensure that the solids content is 6%, adjust the pH of the solution to 8.0, and stir under constant temperature magnetic force Stir continuously in the container for 12h

[0042] (2) The solution described in step (1) is fully mixed and freeze-dried, and the freeze-dried powder is placed in a desiccator after passing through a 100-mesh sieve (saturated KBr solution is placed at the bottom of the container), and the desiccator is placed in a blast In a drying oven, adjust the temperature to 60°C to keep the relative humidity in the dryer at 79%. After 12 hours of reaction, the whey protein isolate-rice bran polysaccharide graft is obtained, and the obtained product is stored in a -20°C refrigerator.

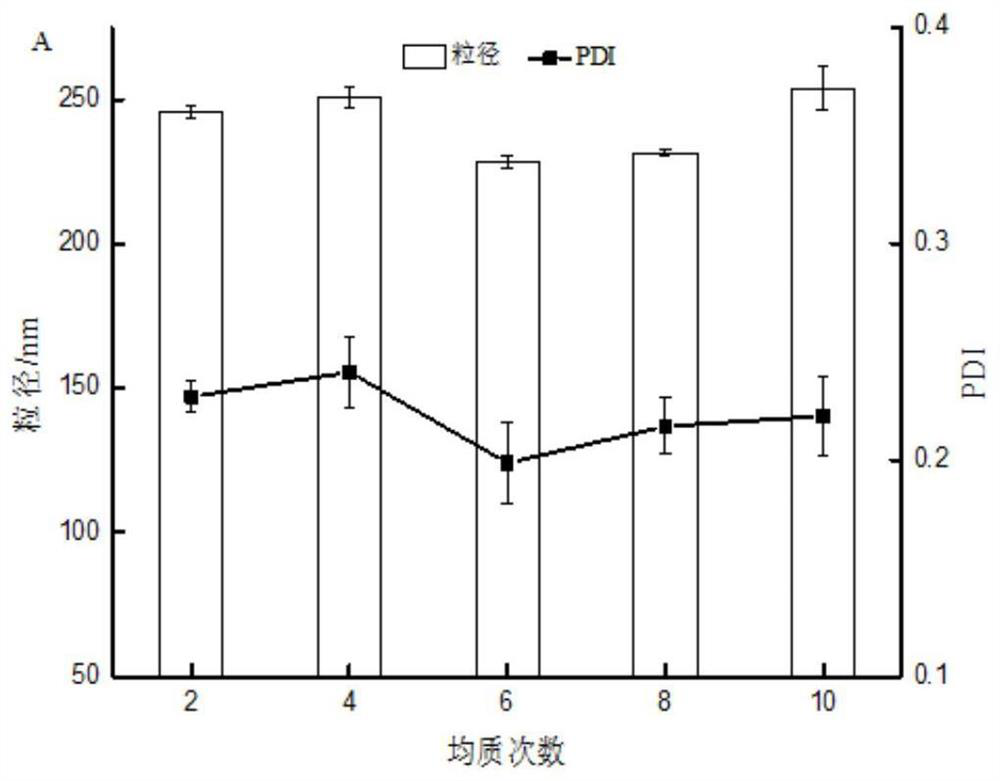

[0043] (3)...

Embodiment 3

[0047] A preparation method of acid-resistant and salt-resistant glycosylated rice bran polysaccharide-whey protein emulsifier, comprising the following steps:

[0048] (1) Dissolve WPI and RBP in 0.1M PBS buffer solution (pH=8.0) according to the ratio of 1:1 (w:w) to ensure that the solids content is 6%, adjust the pH of the solution to 8.0, and stir under constant temperature magnetic force The device was stirred continuously for 12h.

[0049] (2) The solution described in step (1) is fully mixed and freeze-dried, and the freeze-dried powder is placed in a desiccator after passing through a 100-mesh sieve (saturated KBr solution is placed at the bottom of the container), and the desiccator is placed in a blast In a drying oven, adjust the temperature to 60°C to keep the relative humidity in the dryer at 79%. After 12 hours of reaction, the whey protein isolate-rice bran polysaccharide graft is obtained, and the obtained product is stored in a -20°C refrigerator.

[0050] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com