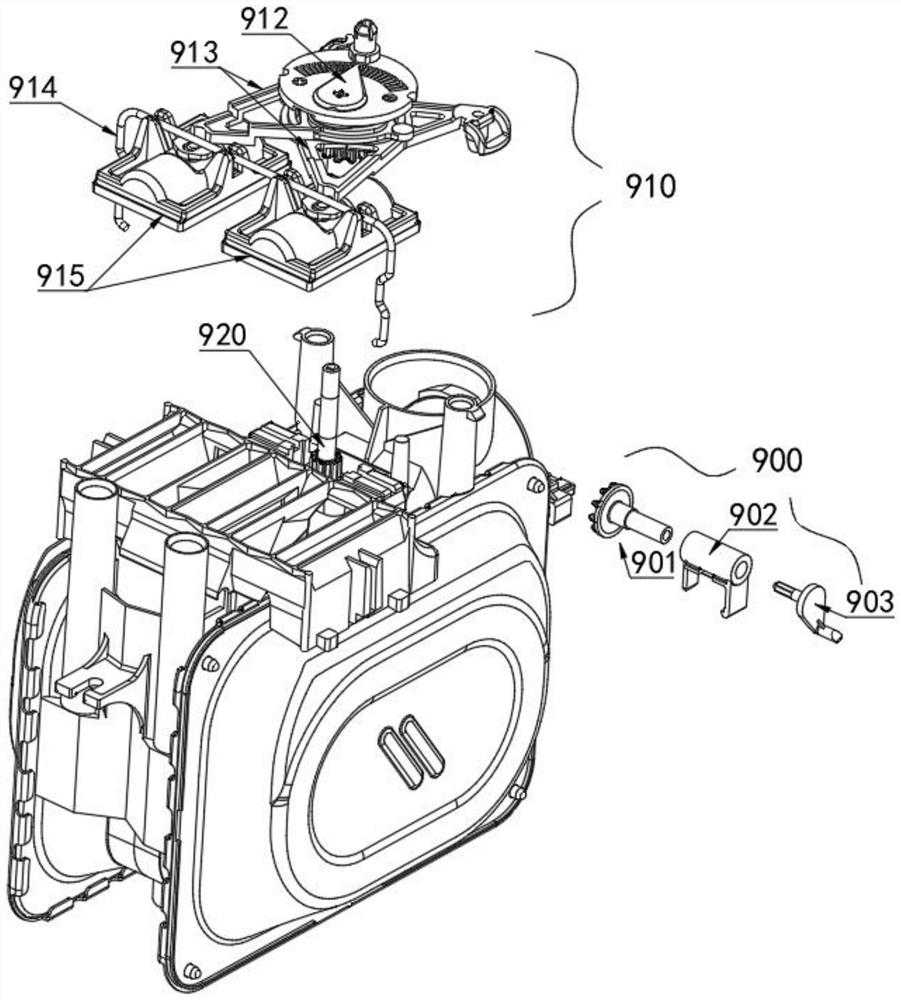

Outlet wheel, outlet wheel feeding mechanism and crank assembly assembling system

A technology of export wheels and mouth wheels, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems that affect product measurement accuracy, poor assembly quality, and many accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

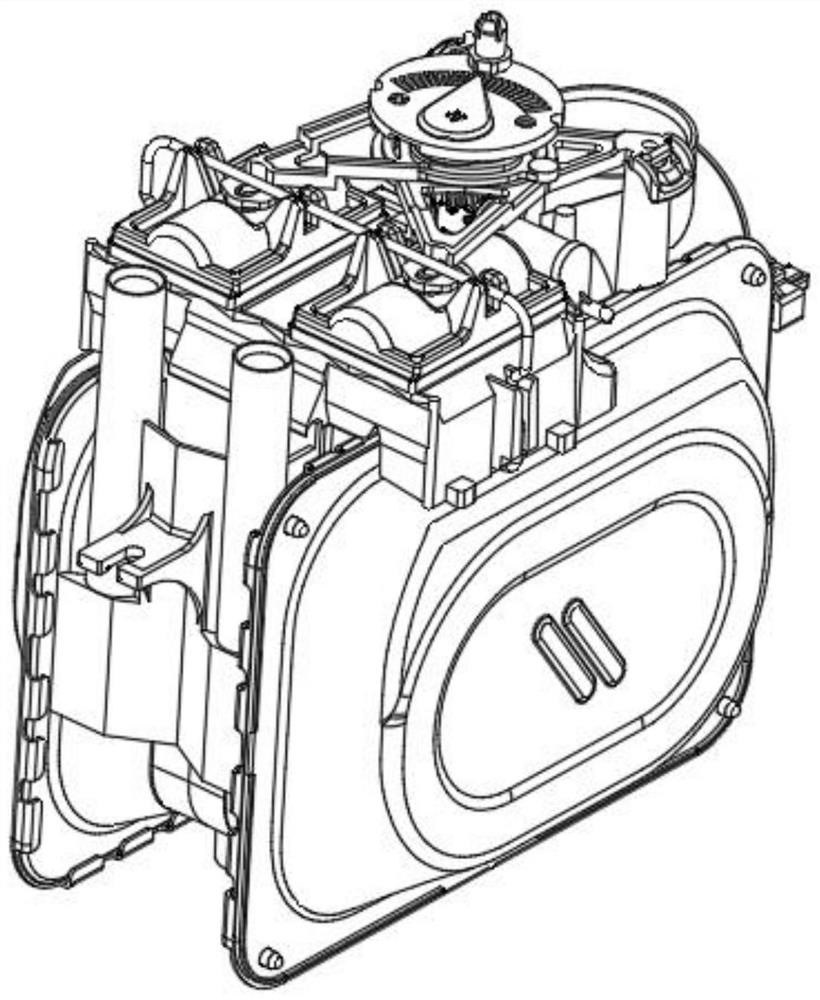

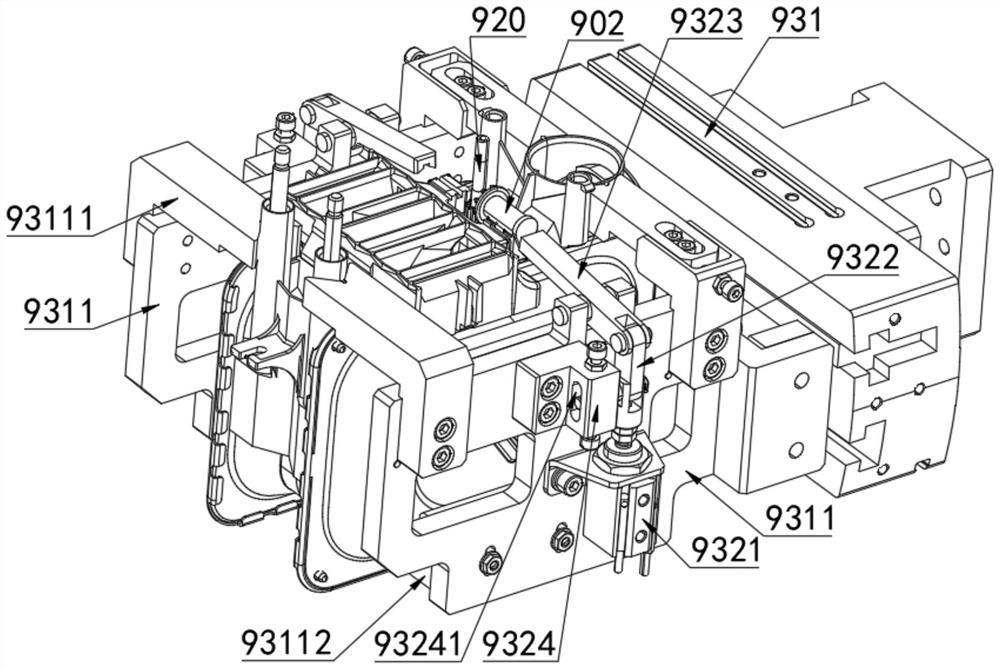

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0052]A. Crank assembly and camshaft assembly method

[0053] Crank assembly and camshaft assembly method, in the process of coaxial press-fitting of the camshaft to the center shaft, in the vertical projection direction of the meshable area between the camshaft and the outlet wheel in the crank assembly: the camshaft The gear teeth on the crank assembly all fall in the gap between two adjacent driving teeth on the outlet wheel in the crank assembly.

[0054] After adopting the above-mentioned technical scheme of the assembly method of the crank assembly and the camshaft, it can be effectively ensured that during the coaxial press-fitting of the camshaft to the center shaft, the gear teeth on the camshaft will not collide with the driving teeth on the outlet wheel in the crank assembly. Collision between each other, thereby avoiding collision pressure loss, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com