Efficient and energy-saving dust removal equipment of belt conveyor

A conveyor belt, high-efficiency and energy-saving technology, used in conveyors, transportation and packaging, using liquid separators, etc., can solve problems such as failure to meet national environmental protection discharge standards, and achieve environmental protection, good economic and social benefits, The effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

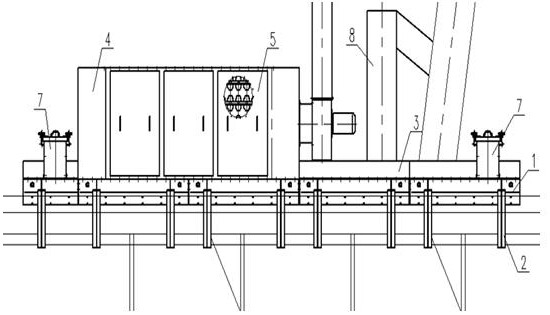

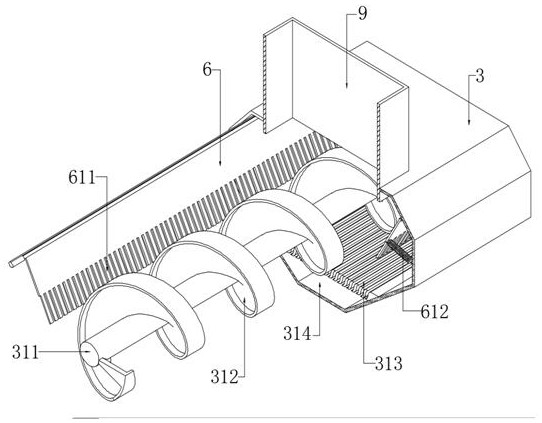

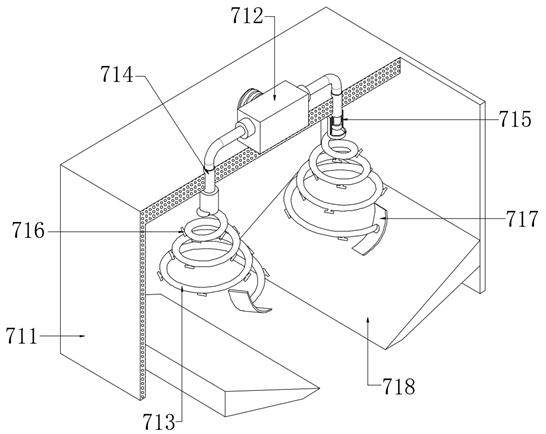

[0024] High-efficiency energy-saving dust removal equipment for conveyor belt conveyors, such as figure 1 , figure 2 with Figure 4 As shown, it includes the sealing groove 1 and the support frame 2 located on the conveyor belt conveyor. The outer wall of the support frame 2 and the lower outer wall of the sealing groove 1 are connected by bolts, and the top of the sealing groove 1 is arranged in sequence from both sides to the middle. The air diversion groove 3, the column 4 and the dust removal box 5, the inside of the flue gas diversion groove 3 is provided with an anti-corrosion and wear-resistant feeding plate 6 and a dust suppression device 7, and the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com