Composition, polymer dispersed liquid crystal, thin film, and electronic equipment

A technology for dispersing liquid crystals and polymers, which is applied in the fields of polymer dispersed liquid crystals, thin films, electronic equipment, and compositions. It can solve problems such as weak binding force and unsuitable application scenarios, so as to improve surface adhesion and improve adhesion The effect of lowering and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

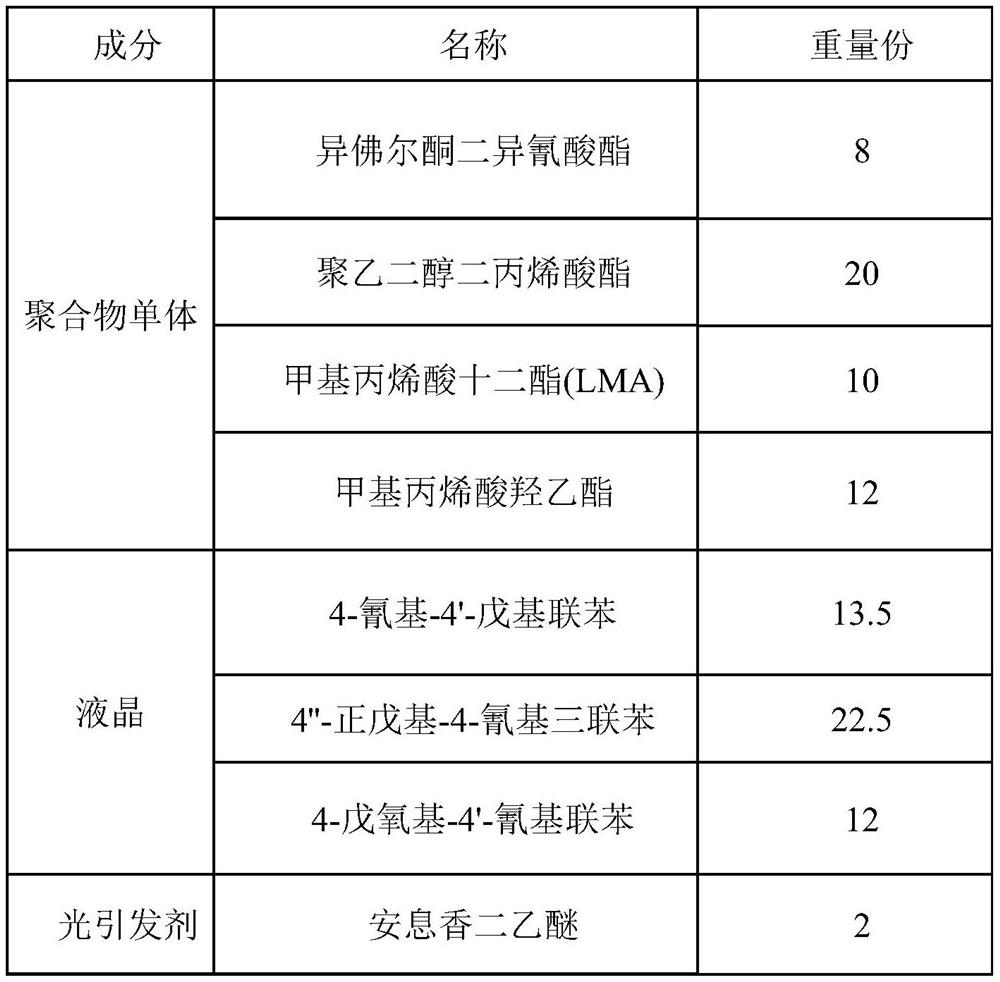

[0043]

[0044] Configure the composition according to the above formula, mix it and place it evenly, use PET / ITO as the conductive film, and the PET / ITO has undergone alkali cleaning and activation treatment before use, and the lotion for alkali cleaning treatment uses 40g / L sodium hydroxide solution, alkali The washing time is 10s, and the alkali washing treatment temperature is room temperature.

[0045] Coat the uniformly mixed composition on the activated PET / ITO, then cover the coated composition with a layer of activated PET / ITO, and cure the composition with ultraviolet light to finally obtain polymer dispersed liquid crystal film.

Embodiment 2

[0047] Example 2 is consistent with Example 1, except that the weight portion of isophorone diisocyanate in Example 2 is 10 parts.

Embodiment 3

[0049] Example 3 is consistent with Example 1, except that in Example 3, the weight part of isophorone diisocyanate is 9 parts, and the weight part of hydroxyethyl methacrylate is 14 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com