1, 3-beta-D-glucan physical gel, and preparation method and application thereof

A physical gel, glucan technology, used in the production of bulk chemicals, etc., to achieve the effect of good frost resistance, good electrical conductivity and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The first object of the present invention is to provide two kinds of preparation methods of 1,3-β-D-glucan organogel, comprising the following steps:

[0066](1) Preparation of 1,3-β-D-glucan solution: Add 1,3-β-D-glucan powder into the first solvent, stir at a certain temperature for a period of time to obtain a transparent polysaccharide solution;

[0067] (2) Preparation of freeze-thaw organogel: freeze the solution obtained in step (1) below the freezing point, take it out and thaw it above the freezing point, and repeat the above-mentioned freeze-thaw process to obtain the freeze-thaw organogel; is the first organogel;

[0068] (3) Preparation of organogel by solvent replacement method: all or part of the first solvent in the freeze-thaw gel obtained in step (2) is replaced by the second solvent to obtain the second organogel.

[0069] In the method provided by the present invention, the organogel can be formed by freezing and thawing, and can also be formed by s...

Embodiment 1

[0113]The present embodiment provides a preparation method of curdlan organogel, comprising the following steps:

[0114] (1) Accurately weigh 2.5g of curdlan powder, slowly add it into 50g of DMSO solution while stirring, stir at 90°C for 4 hours, and rotate at 500rpm. Under this condition, the curdlan is fully dissolved, and sealed after cooling spare.

[0115] (2) Slowly pour the solution obtained in step (1) into a polytetrafluoroethylene mold, seal it, vacuum degass it for 6 hours, and store it sealed for 7 days. Place it in a low-temperature refrigerator and freeze it at -20°C for 24 hours. After taking it out, Thaw at room temperature for 4 hours, and take out the organogel from the mold after one freeze-thaw treatment. The organogel was tested for compressive properties, and when the compressive strain was 60%, its compressive strength was 37.6kPa.

Embodiment 2

[0117] The present embodiment provides a preparation method of curdlan organogel, comprising the following steps:

[0118] (1) Accurately weigh 2.5g of curdlan gum powder, slowly add in 50g of DMSO solution while stirring, stir at room temperature for 12 hours, rotating speed 500rpm, seal for later use.

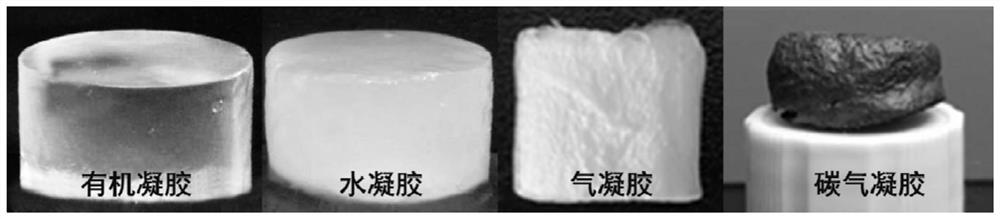

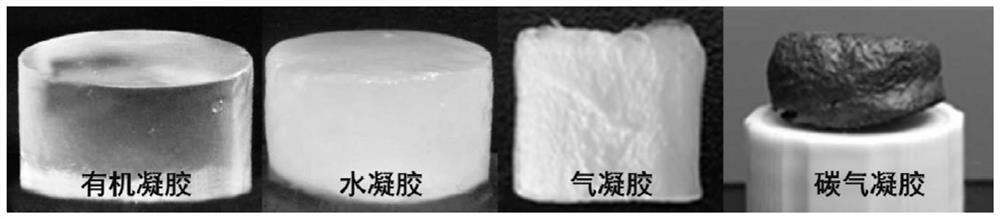

[0119] (2) Slowly pour the solution obtained in step (1) into a polytetrafluoroethylene mold and seal it. After vacuum degassing for 6 hours, seal it and store it for 7 days. Place it in a low-temperature refrigerator and freeze it at -20°C for 24 hours. Take it out Then place it at room temperature to thaw for 4 hours, and take out the organogel from the mold after one freeze-thaw treatment. The photo of the gel in the optical camera see figure 1 , the resulting organogel was tested for compressive properties, and when the compressive strain was 60%, its compressive strength was 70.5kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com