Equipment and method for solving blast furnace alkali metal furnace wall nodulation and furnace charge surface dewing

An alkali metal and alkali metal compound technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as increased operating energy consumption, increased material downward resistance, reduced smelting efficiency, etc., to reduce overall energy consumption and reactivity. The effect of improving and improving smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

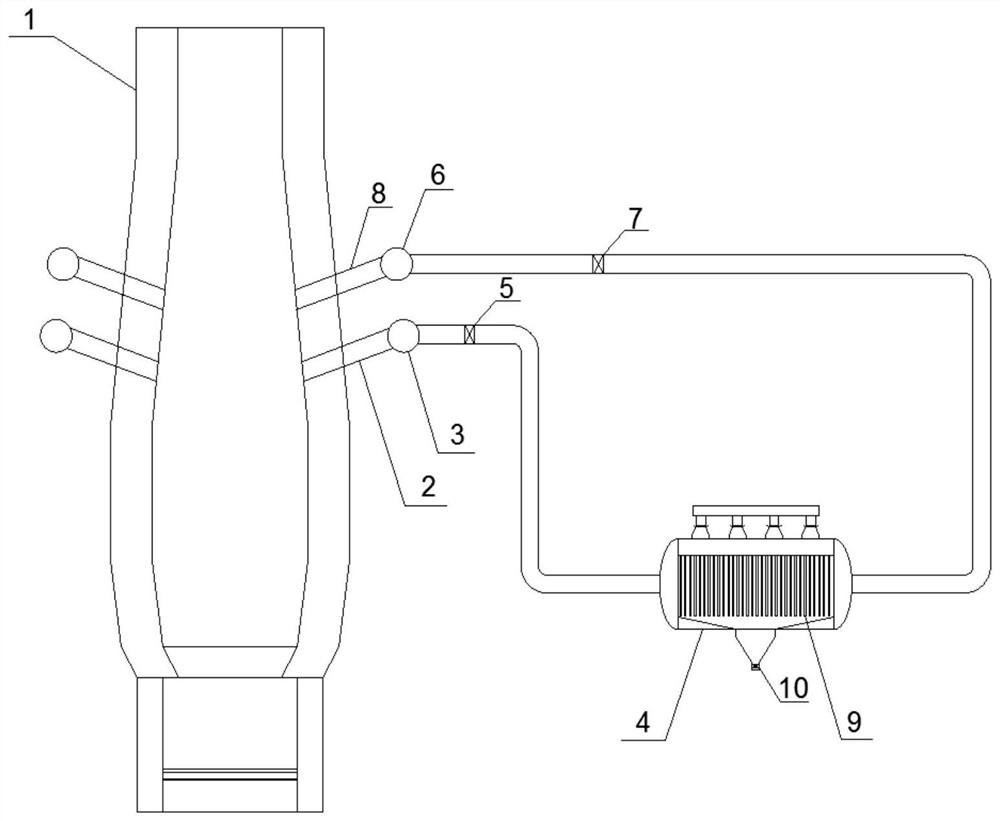

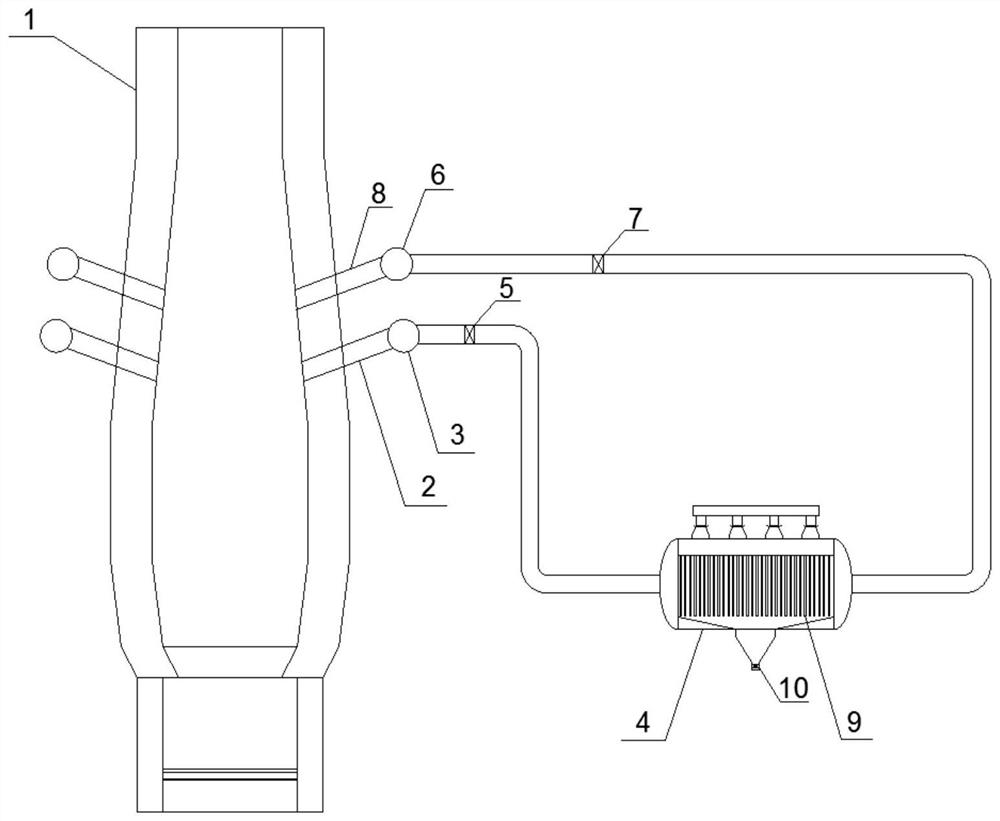

[0068] A steel company 1200m 3 In the blast furnace, due to the heavy load of alkali metal in the furnace charge, alkali metal enrichment is often formed, causing multiple nodules in the furnace, increasing the resistance of the blast furnace, and deteriorating the reactivity of the charge, which seriously affects the smooth operation of the blast furnace smelting. For this reason, during the overhaul, the blast furnace is transformed with this technology. Schematic diagram of the equipment structure for solving the nodulation on the alkali metal wall of the blast furnace and the dew condensation on the surface of the charge after the transformation. figure 1 As shown, specifically:

[0069] 1. Around the position where the furnace body of blast furnace 1 normally smelts at 800°C, eight furnace gas outlet pipes 2 are arranged symmetrically and evenly. The equipment 4 is connected with each other, the valve 5 is set in the middle of 3 and 4, the tail of the alkali metal remov...

Embodiment 2

[0081] A steel company 1200m 3 In the blast furnace, due to the heavy load of alkali metal in the furnace charge, alkali metal enrichment is often formed, causing multiple nodules in the furnace, increasing the resistance of the blast furnace, and deteriorating the reactivity of the charge, which seriously affects the smooth operation of the blast furnace smelting. For this reason, during the overhaul, the blast furnace is transformed with this technology. Schematic diagram of the equipment structure for solving the nodulation on the alkali metal wall of the blast furnace and the dew condensation on the surface of the charge after the transformation. figure 1 As shown, specifically:

[0082] 1. Around the position where the furnace body of blast furnace 1 normally smelts at 850°C, eight furnace gas outlet pipes 2 are arranged symmetrically. The 4 phases are connected, the valve 5 is set in the middle of 3 and 4, the tail of the alkali metal removal equipment 4 is connected w...

Embodiment 3

[0089] A steel company 1080m 3In the blast furnace, due to the heavy load of alkali metal in the furnace charge, alkali metal enrichment is often formed, causing multiple nodules in the furnace, increasing the resistance of the blast furnace, and deteriorating the reactivity of the charge, which seriously affects the smooth operation of the blast furnace smelting. For this reason, during the overhaul, the blast furnace is transformed with this technology. Schematic diagram of the equipment structure for solving the nodulation on the alkali metal wall of the blast furnace and the dew condensation on the surface of the charge after the transformation. figure 1 As shown, specifically:

[0090] 1. Around the position where the furnace body of blast furnace 1 normally smelts at 750°C, eight furnace gas outlet pipes 2 are arranged symmetrically. The 4 phases are connected, the valve 5 is set in the middle of 3 and 4, the tail of the alkali metal removal equipment 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com