System for efficiently recovering industrial low-temperature waste heat and flexibly regulating peak for new energy

A low-temperature waste heat and new energy technology, applied in heat pumps, refrigeration and liquefaction, climate sustainability, etc., can solve the problems of inability to use rich new energy, increase carbon emissions, etc., achieve high COP value, save compression energy, and improve efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

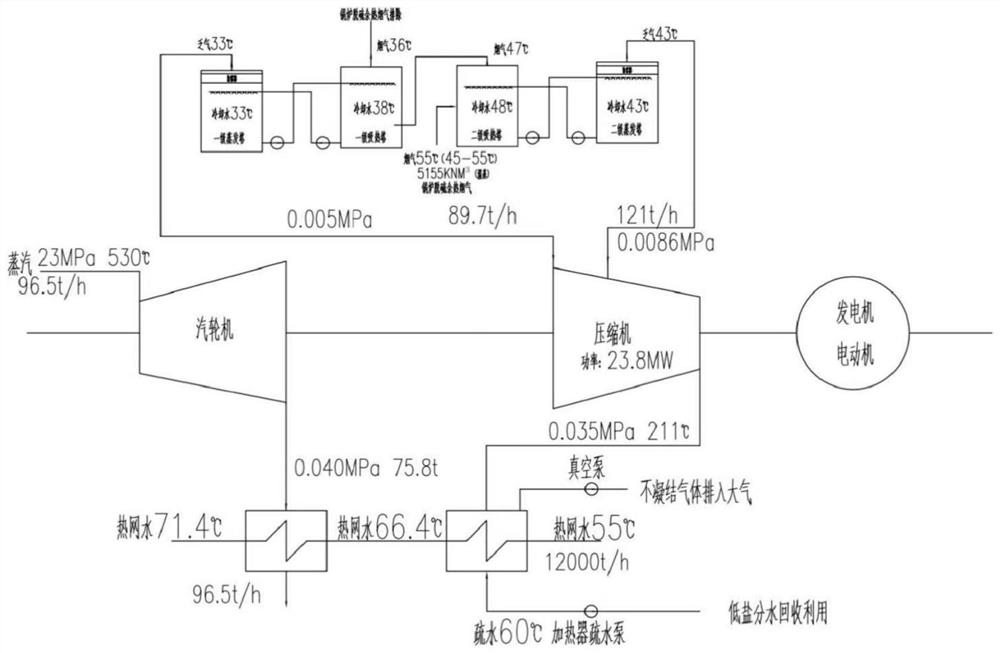

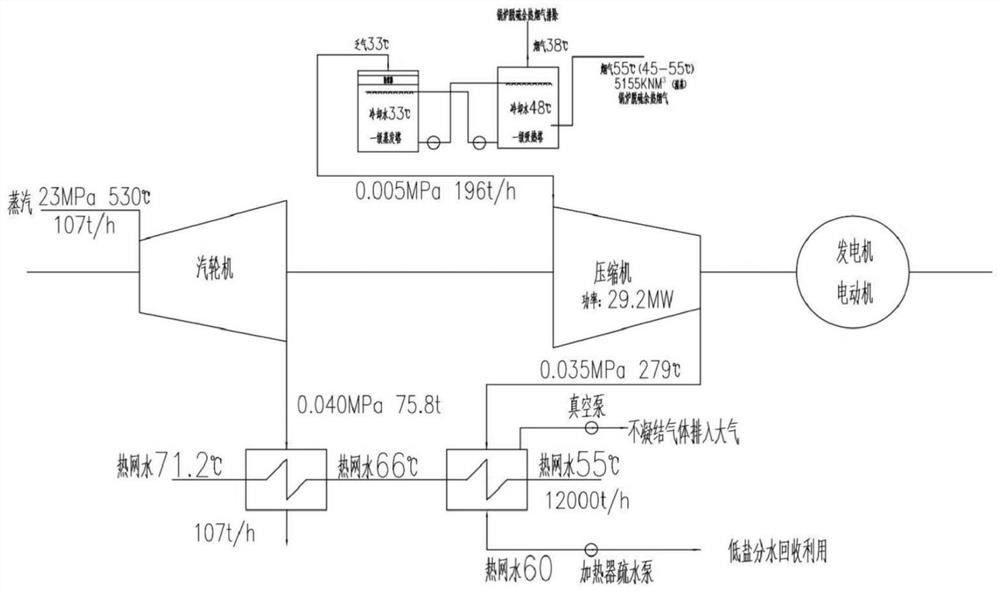

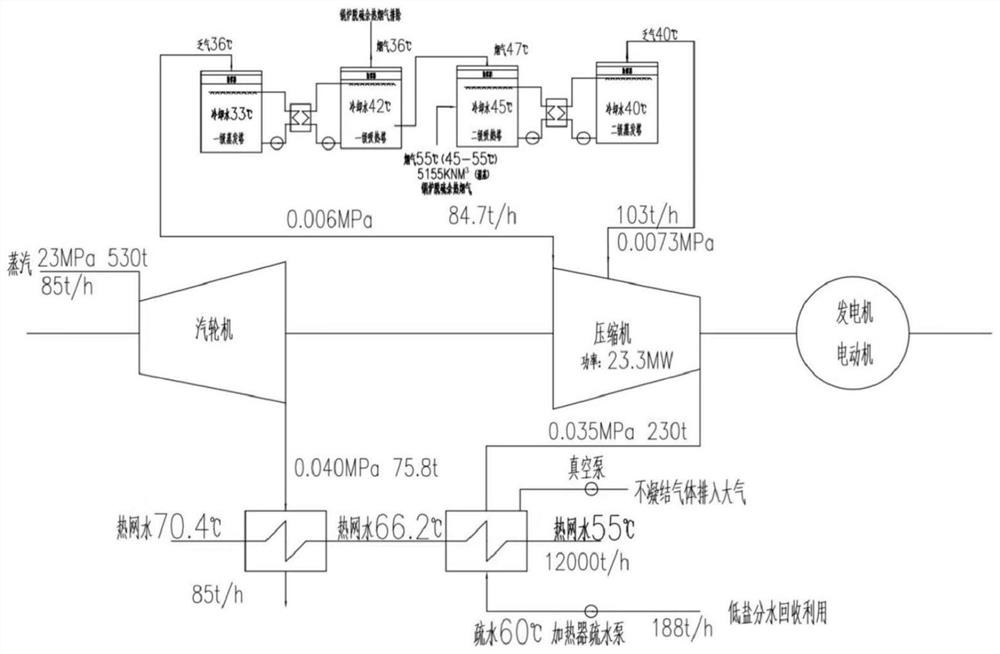

[0057] A system for efficiently recovering industrial low-temperature waste heat and flexible peak regulation for new energy sources, including: Step A: Cooling of desulfurized flue gas from the heat absorbing tower and energy recovery process:

[0058] A1: The desulfurization 5515 thousand standard cubic meters of wet flue gas in the first-level heat absorption tower and the cooling flow rate of 15000t / h from the evaporation tower are directly mixed and contacted with the cooling water and the desulfurization flue gas to reduce the temperature of the flue gas and recover the latent heat of vaporization of the flue gas water vapor; The desulfurization 5515 thousand standard cubic wet flue gas in the stage heat absorption tower and the cooling flow rate of 11000t / h from the evaporation tower are directly mixed and contacted by the cooling water and the desulfurization flue gas to reduce the temperature of the flue gas, recover the latent heat of vaporization of the flue gas water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com