Radioactive waste gas treatment method and system for isotope production line

A technology of waste gas treatment and treatment system, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of personnel hazards, increase radiation, reduce drying capacity and adsorption capacity, and achieve the effect of reducing replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

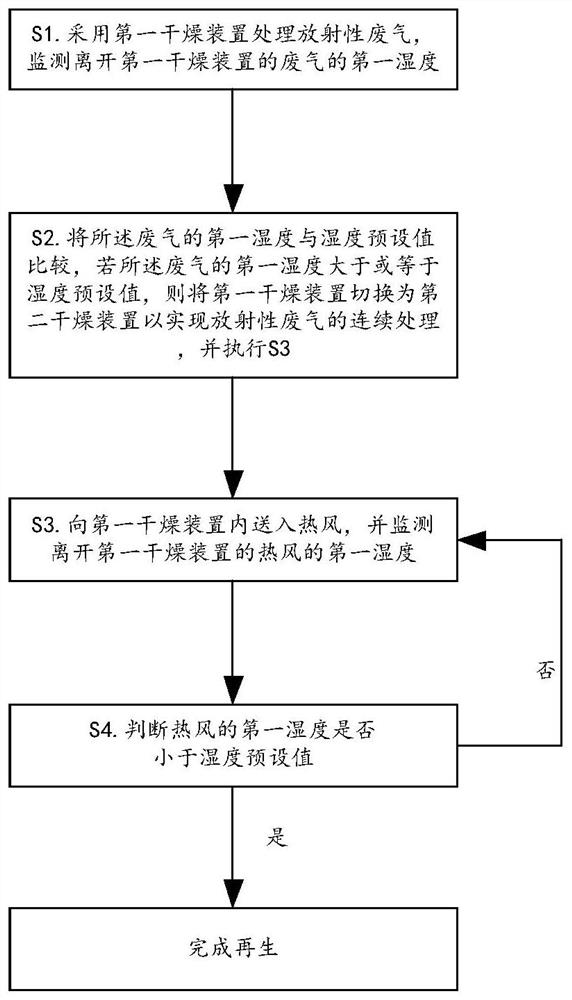

[0061] In order to reduce the replacement of silica gel without affecting the treatment of radioactive waste gas, in the first aspect, the embodiment of the present invention provides a method for treating radioactive waste gas of an isotope production line. figure 2 shown, including:

[0062] S1. Using the first drying device to treat the radioactive waste gas, and monitoring the first humidity of the waste gas leaving the first drying device;

[0063] S2. Comparing the first humidity of the waste gas with the preset humidity value, if the first humidity of the waste gas is greater than or equal to the preset humidity value, then switch the first drying device to the second drying device to realize the purification of the radioactive waste gas Continuous processing, and execute S3;

[0064] S3. Sending hot air into the first drying device, and monitoring the first humidity of the hot air leaving the first drying device;

[0065] S4. Determine whether the first humidity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com