Semiconductor processing plastic packaging machine

A plastic sealing machine and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as easy generation of air bubbles, delamination of raw materials and semiconductors, etc., to avoid wrinkles, reduce possibilities, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

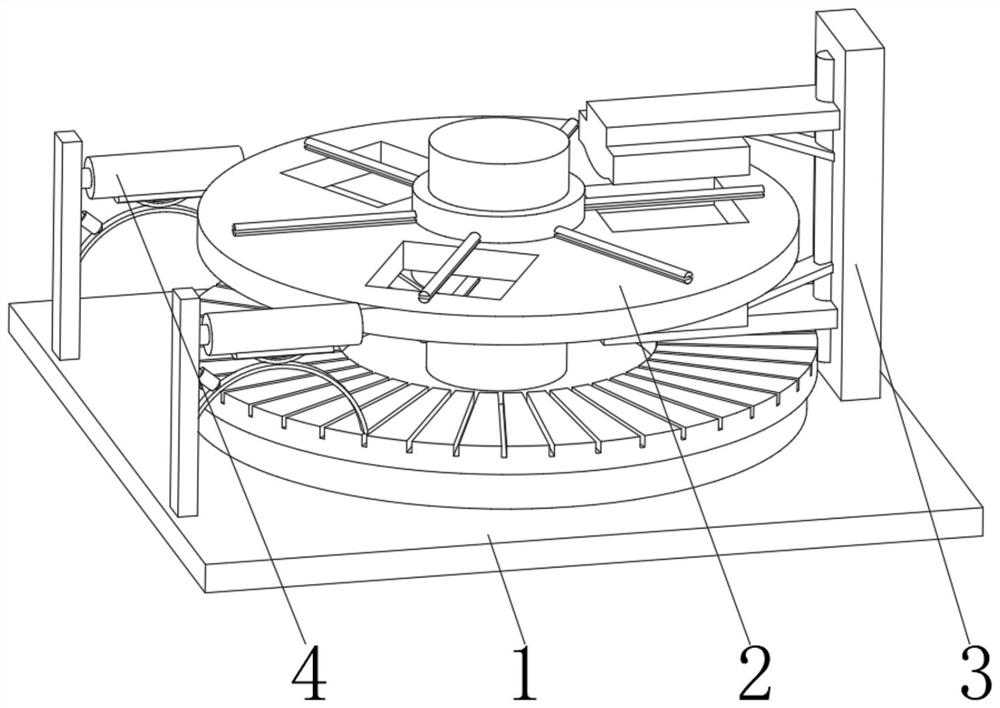

[0037] see Figure 1-3 , the present invention provides a technical solution: a semiconductor processing plastic sealing machine, specifically comprising:

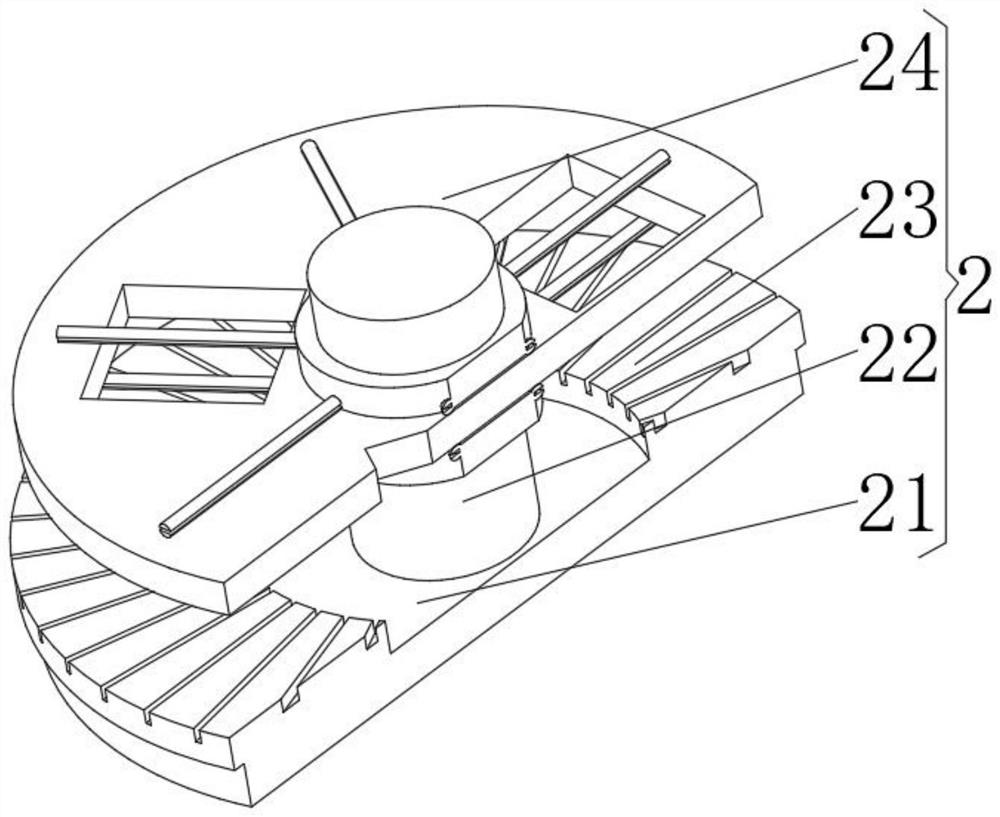

[0038] Base plate 1, the base plate 1 has a square seat plate, and a plastic sealing platform 2 installed in the middle of the top of the square seat plate, and a heat pressing mechanism 3 installed on the right side of the top of the square seat plate, and installed on the left side of the top of the square seat plate The feeding mechanism 4 at the front and back positions of the side, and the plastic sealing platform 2 include:

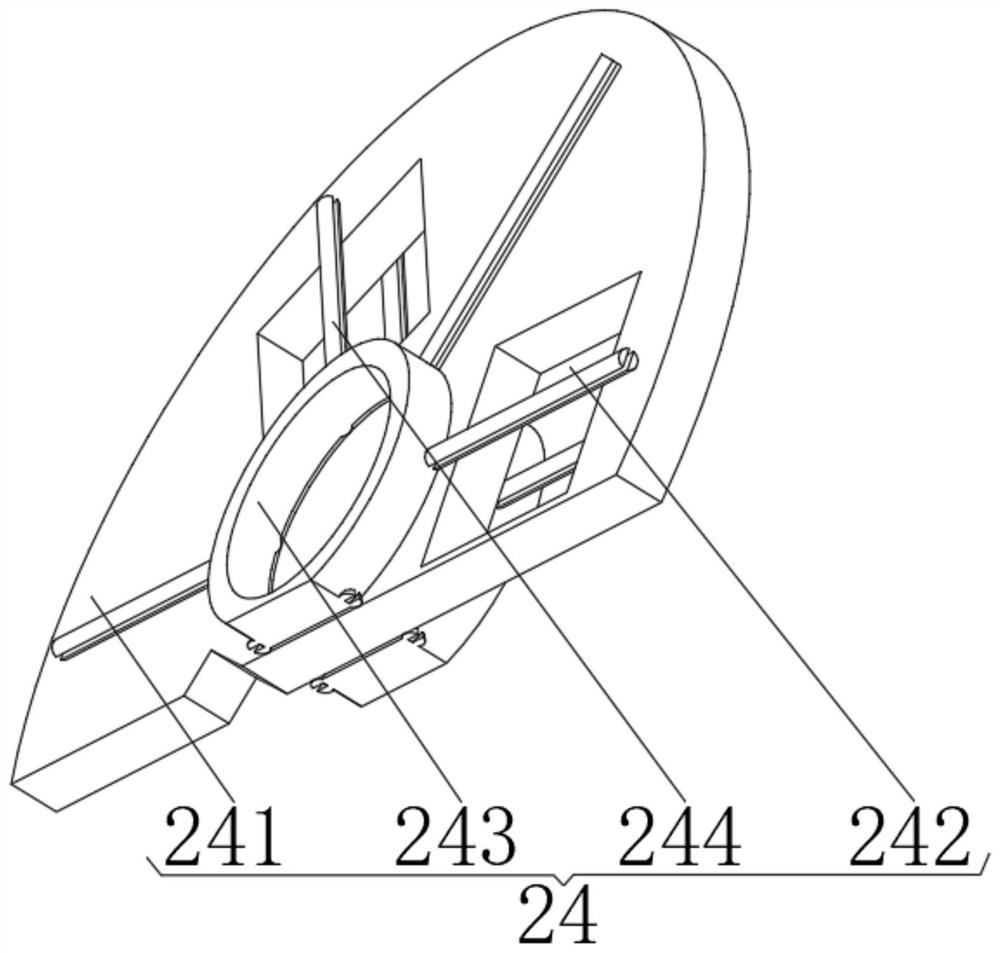

[0039] Electromagnetic plate 21, the electromagnetic plate 21 has an annular plate body, and a multi-section driving column 22 installed on the inner surface of the annular plate body, and a friction power generation ring plate 23 installed on the outer surface of the top of the annular plate body, and installed on the outer surface of the multi-section driving column 22 The object stage 24 of ...

Embodiment 2

[0046] see Figure 1-4 , On the basis of Embodiment 1, the present invention provides a technical solution: the hot pressing mechanism 3 includes:

[0047] A positioning frame 31, the positioning frame 31 has a rectangular plate body, and a track column 32 installed in the middle of the side of the rectangular plate body close to the plastic sealing platform 2, and a splint 33 installed on the outer surface of the track column 32, and installed on the inner surface of the splint 33 The heat press 34 on the side away from the track column 32 is installed on the cylinder contact plate 35 on the side of the heat press 34 away from the splint 33. The splint 33 is set as a molded plate body, and the bottom of the positioning frame 31 is installed on the base plate 1 top. Through the design of the cylindrical contact plate 35, the plastic raw materials and semiconductors are plastic-encapsulated from the inside to the outside, and the internal air is discharged in advance by using ...

Embodiment 3

[0050] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the feeding mechanism 4 includes:

[0051] Fixed plate 41, the fixed plate 41 has a long strip body, and the feeding shaft column 42 installed on the top of the strip body, and the adjustment column rod installed on the surface of the strip body and positioned directly below the feeding shaft column 42 43, and the arc strut 44 that is installed on the other end of the adjustment pole 43, and the reverse arc bar 45 that is fixed on the top of the arc strut 44, and the flat plate 46 that is fixed on the reverse arc bar 45. Through the design of the leveling plate 46, the height of the plastic raw material is limited horizontally to avoid the change of the horizontal height due to the consumption of the plastic raw material roll, and at the same time, the plastic raw material is flattened to ensure the smoothness of the plastic raw material surface.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com