Cigar production method

A production method and technology for cigars are applied in the directions of tobacco, tobacco cultivation, tobacco preparation, etc., and can solve the problems that the quality of finished cigars needs to be improved, and there is no differentiated processing of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

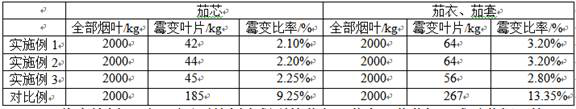

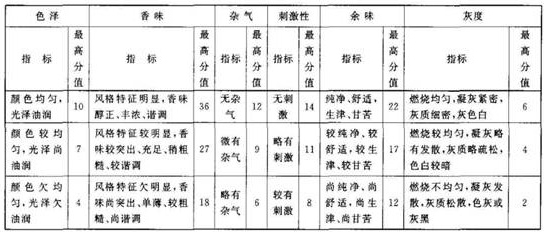

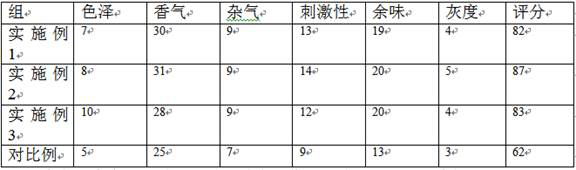

Examples

Embodiment 1

[0024] The present invention is a kind of production method of cigar, comprises the following steps:

[0025] (1) Site preparation, ridging, and then transplanting, the planting density of filler tobacco plants in the transplanting: single row planting, row spacing 110cm×35cm, tobacco planting density 1600 plants / mu, wrapper wrapper tobacco plants Planting density: row spacing 120cm×35cm, tobacco planting density 1400 plants / mu;

[0026] The distance between the ridges is 110-120cm according to the terrain and soil strength, and the height of the ridges is 25-35cm. The ridges are full and the surface is flat and turtle-like. Shading is required after transplanting, and wrapper tobacco leaves can be cultivated in shade to reduce sunlight and increase relative humidity in the field. The shading material generally adopts a white sunshade net with a light transmittance of about 65%. Shade is started after the tobacco plants are clustered, and the relative humidity in the field c...

Embodiment 2

[0037] The present invention is a kind of production method of cigar, comprises the following steps:

[0038] (1) Site preparation, ridging, and then transplanting, the planting density of filler tobacco plants in the transplanting: single row planting, row spacing 120cm×35cm, tobacco planting density 1800 plants / mu, wrapper wrapper tobacco plants Planting density: row spacing 120cm×40cm, tobacco planting density 1600 plants / mu;

[0039] (2) Fertilize, irrigate and top the tobacco leaf plants;

[0040] (3) Harvest and air-dry the tobacco leaves after they are mature. During the drying process, the filler tobacco leaves are air-dried by tying tobacco rods to the tobacco leaves, and the wrapper tobacco leaves are air-dried by needles and hanging rods. The air-drying time is After 35 days, the moisture content of the dried tobacco leaves was 18%;

[0041] (4) Remoisturize the tobacco leaves after grading the tobacco leaves. The temperature of the tobacco leaf remoisture describ...

Embodiment 3

[0044] The present invention is a kind of production method of cigar, comprises the following steps:

[0045] (1) Site preparation, ridging, and then transplanting, the planting density of filler tobacco plants in the transplanting: single row planting, row spacing 115×35cm, tobacco planting density 1700 plants / mu, wrapper wrapper tobacco plants Planting density: row spacing 120cm×38cm, tobacco planting density 1500 plants / mu;

[0046] (2) Fertilize, irrigate and top the tobacco leaf plants;

[0047] (3) Harvest and air-dry the tobacco leaves after they are mature. During the drying process, the filler tobacco leaves are air-dried by tying tobacco rods to the tobacco leaves, and the wrapper tobacco leaves are air-dried by needles and hanging rods. The air-drying time is In 30 days, the moisture content of the dried tobacco leaves was 17%;

[0048] (4) After grading the tobacco leaves, rehydrate the tobacco leaves. The temperature of the tobacco leaves rehydrated in step (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com