Preparation method and device of high-tap-density and high-stability ceramic green body

A technology of tap density and high stability, applied in supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of unstable quality and low efficiency of manual filling of molds, so as to maintain stable quality and avoid green body density. Inequality, effects of control variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

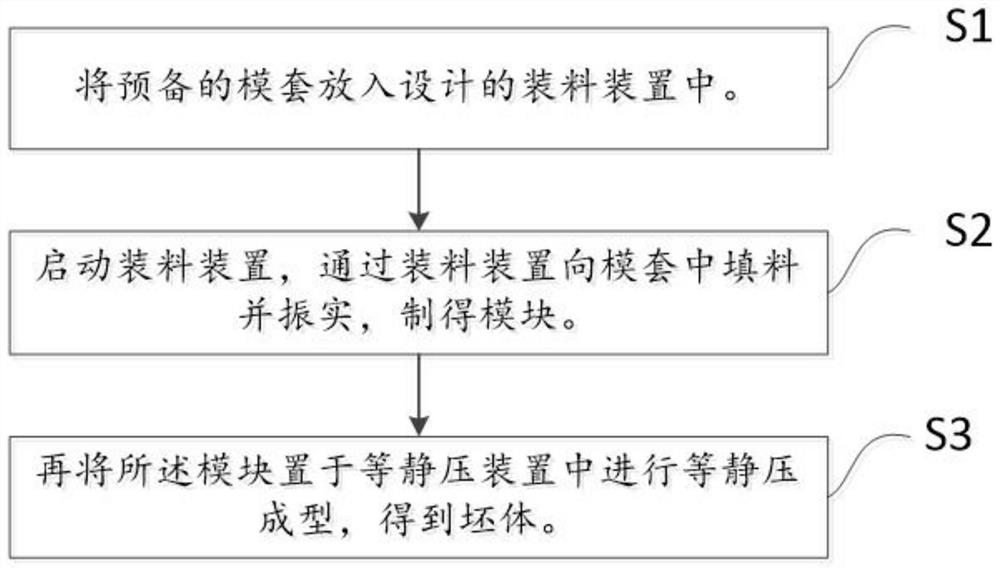

[0054] A method for preparing a high-tap density and high-stability ceramic green body provided by the first embodiment of the present invention, such as figure 1 shown, including the following steps:

[0055] Step S1: Put the prepared mold case into the designed charging device.

[0056] In this embodiment, in the process of preparing the ceramic green body, the step of manually adding ceramic powder to the mold before the isostatic pressing process is eliminated, and the prepared mold is selected to be placed in a designed device for Automatic loading saves manpower spent on manual loading.

[0057] Step S2: Start the charging device, fill and vibrate the mold casing through the charging device, and obtain the module.

[0058] In this embodiment, the preset charging device can perform automatic feeding. After the device is started, ceramic powder is automatically added to the mold sleeve at a preset speed. In practice, it is possible to finely control the amount of feedin...

Embodiment 2

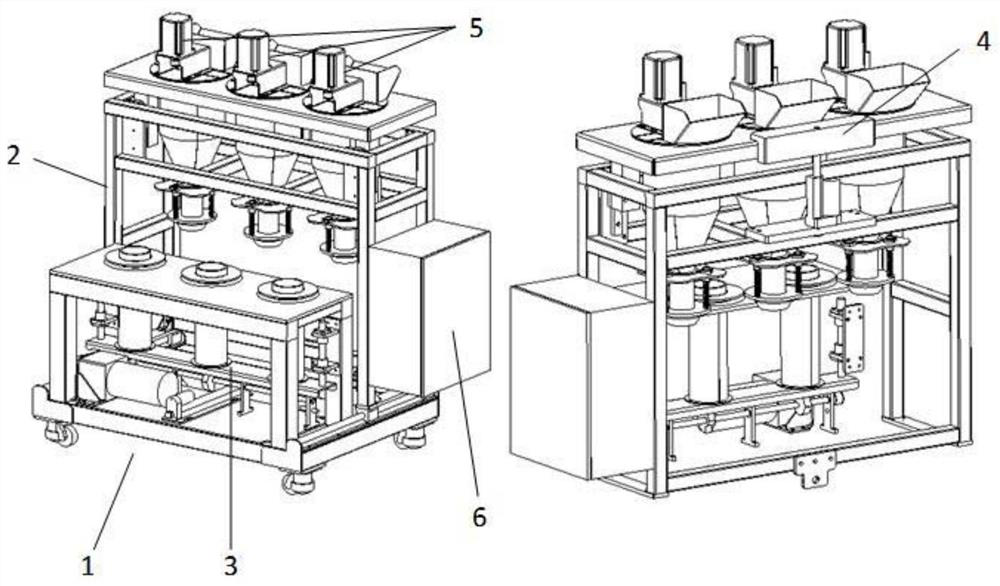

[0064] Based on the method for preparing a high-tap density and high-stability ceramic body, the second embodiment of the present invention provides a device for preparing a high-tap density and high-stability ceramic body. to perform the above method. Such as figure 2 As shown, the device mainly includes: an underframe 1, a moving frame 2, a vibration module 3, a lifting module 4, a feeding module 5 and an electric control box 6;

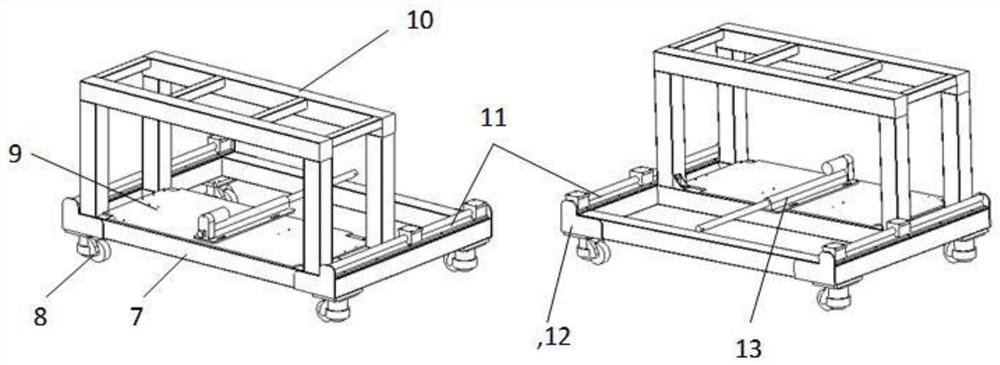

[0065] The feeding module 5 is installed on the lifting platform of the lifting module 4, and the lifting module 4 controls the feeding module 5 to move up and down. The lifting module 4 is installed on the moving frame of the moving frame 2, and the moving frame 2 drives the lifting module 4 to move horizontally. The mobile frame 2 is horizontally slidingly connected with the bottom frame 1 through the horizontal guide rails arranged on both sides of the bottom frame 1 . The vibration module 3 is installed on the vibration mechanism supporting...

Embodiment 3

[0090] This embodiment is a further example based on Embodiment 2, and the similarities will not be repeated. In this embodiment, the steel sleeve 24 equipment with an inner diameter of 105 mm and a length of 400 mm is used to prepare a zirconia ceramic green body as follows: example.

[0091] Step 1: Add ZrO 2 20 kg of ceramic powder is added into the barrel of the feeding module 5 through the feeding port 41, and a rubber mold cover with a diameter of 100 mm and a height of 400 mm is placed in the vibrating module 3 .

[0092] Step 2: Set the charging height on the electric control box 6 to 400 mm, the speed of the feeding motor to 40 rpm, the number of vibrations to 400 times, and the vibration speed to 50 times / min; start the device and start feeding.

[0093] Step 3: After the feeding is finished, continue to vibrate for 300 times, the device stops, and the module is taken out.

[0094] Step 4: Repeat the above operation 5 times to obtain 15 loaded molds;

[0095] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com