High-bending-strength low-temperature co-fired ceramic material for microwave substrate and preparation method of high-bending-strength low-temperature co-fired ceramic material

A low-temperature co-fired ceramic and microwave substrate technology, which is applied in the field of low-temperature co-fired ceramics, can solve the problems of small process tolerance and poor mechanical properties of microwave substrates, and achieve the effects of reducing package line width, simplifying circuit design, and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

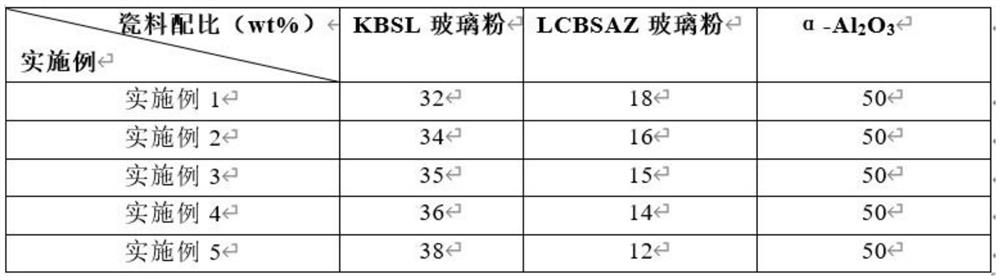

[0030] Adopt low temperature co-fired ceramic material as follows in the embodiment 1~5:

[0031] A low-temperature co-fired ceramic material with high flexural strength for microwave substrates, including KBSL glass, LCBSAZ glass, and α-Al 2 o 3 ; The KBSL glass, LCBSAZ glass, and α-Al 2 o 3 The mass ratio is 32~38:12~18:50.

[0032] Further, the KBSL glass includes K 2 O.B 2 o 3 , SiO 2 , La 2 o 3 ; the K 2 O.B 2 o 3 , SiO 2 , La 2 o 3 The mass ratio is 56.2:37.1:5.4:1.3.

[0033]Further, the LCBSAZ glass includes Li 2 O, CaO, B 2 o 3 , SiO 2 , α-Al 2 o 3 , ZrO 2 ; The Li 2 O, CaO, B 2 o 3 , SiO 2 , α-Al 2 o 3 , ZrO 2 The mass ratio is 2.9:24.3:7.3:53.4:9.7:2.4.

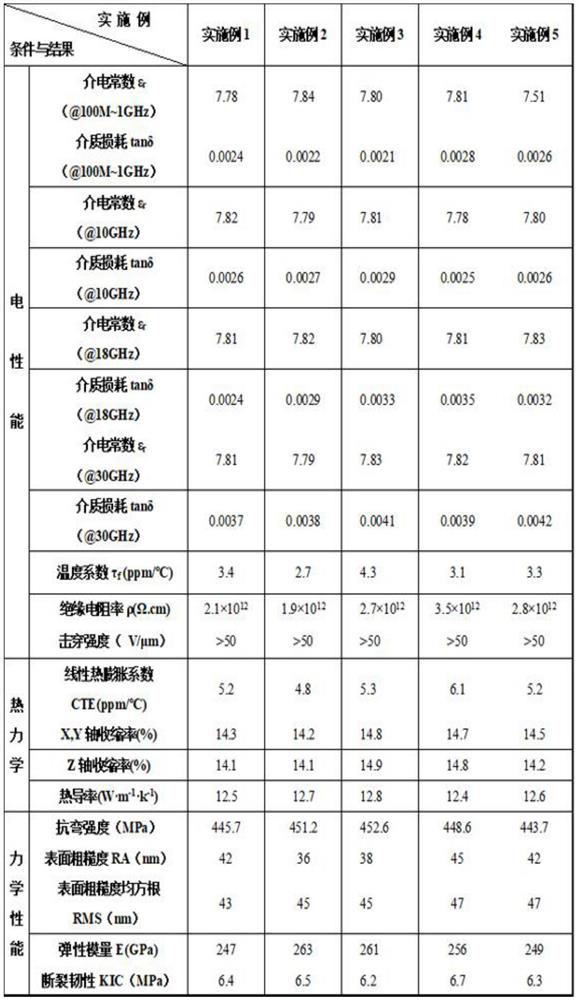

[0034] By adopting the above-mentioned low-temperature co-fired ceramic material, the flexural strength of the material can be increased as much as possible on the basis of ensuring high electrical quality and high thermal quality, thereby improving the adaptability of the material. L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com