Preparation method of low-acrylonitrile 2-acrylamido-2-methylpropanesulfonate

A technology of methylpropanesulfonate and acrylamide, which is applied in the field of compound preparation, can solve the problem of how to prepare, low 2-acrylamido-2-methylpropanesulfonate, acrylonitrile, etc. problems, to achieve the effect of stability, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

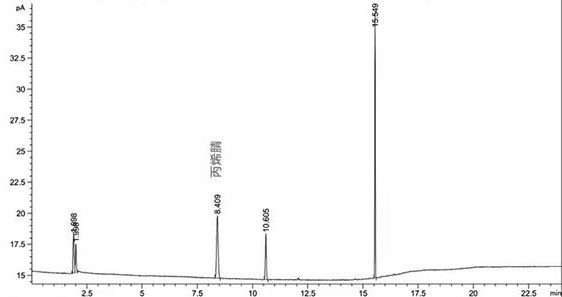

Image

Examples

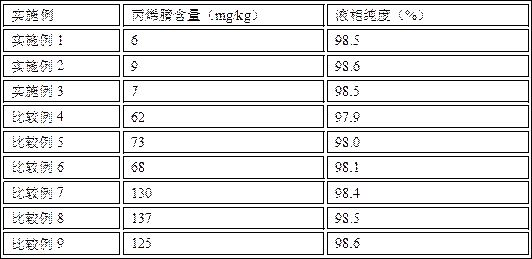

Embodiment 1

[0036]Add 543kg of 32% liquid caustic soda and 555kg of water into the 2000L reactor, turn it on to cool down, start to add 900kg of 2-acrylamido-2-methylpropanesulfonic acid powder, and after the addition is completed, add 1.34kg of sodium sulfite (sodium sulfite and The molar ratio of acrylonitrile is 2:1), add 0.14kg of polymerization inhibitor, control the temperature in the kettle to 35°C, after stirring for 2 hours, the pH becomes 12.60, then slowly add AMPS powder to adjust the pH, and the adding time is 10min, The dosage is 2.5kg, and the pH in the kettle is adjusted to 9.50.

[0037] After adding AMPS, adjust the pH value, continue stirring for 30 minutes, stop stirring, and maintain the temperature in the kettle at 20°C. During this period, the pH of the product is continuously checked until the pH value does not rise again, and the time is 1.5 hours. Start stirring again, add a little sulfuric acid to readjust the pH to 9.45, and discharge to obtain 2-acrylamido-2-m...

Embodiment 2

[0039] Add 543kg32% liquid caustic soda and 555kg water to the 2000L reactor, add 1.34kg sodium sulfite (the molar ratio of it to acrylonitrile in the product is 2:1), turn on the cooling, and start to add 2-acrylamido-2-methylpropane Sulfonic acid powder 900kg, after adding, add 0.14kg of polymerization inhibitor, control the temperature in the kettle to 30°C, stir for 2 hours, the pH becomes 12.20, then slowly add AMPS powder to adjust the pH, adding time 8min, dosage 2.4 kg, adjust the pH in the kettle to 9.80.

[0040] After adding AMPS, adjust the pH value, continue stirring for 30 minutes, stop stirring, and maintain the temperature in the kettle at 20°C. During this period, the pH of the product is continuously checked until the pH value does not rise again. The time is 1 hour, start stirring again, add a little sulfuric acid to readjust the pH to 9.45, and discharge to obtain 2-acrylamido-2-methylpropanesulfonate solution , after testing, the content of acrylonitrile ...

Embodiment 3

[0042] Add 543kg32% liquid caustic soda and 555kg water into the 2000L reactor, turn on the cooling, start to add 900kg of 2-acrylamido-2-methylpropanesulfonic acid powder, add about half of it, add 1kg of sodium sulfite (it is mixed with the product The mass ratio of acrylonitrile is 1.5:1), and continue to feed 2-acrylamido-2-methylpropanesulfonic acid powder. After feeding, add 0.14kg of polymerization inhibitor, control the temperature in the kettle to 35°C, and stir for 2h. The pH became 12.40, and then began to slowly add AMPS powder to adjust the pH. The addition time was 10 minutes, the dosage was 2.0kg, and the pH in the kettle was adjusted to 9.60.

[0043] After adding AMPS, adjust the pH value, continue stirring for 30 minutes, stop stirring, and keep the temperature at 20°C. During this period, the pH of the product is continuously checked until the pH value does not rise any more. The time is 1h20min. Then start stirring again, add a little hydrochloric acid to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com