Horizontal copper and tin plating equipment for circuit board micropores with high aspect ratio

A high aspect ratio, microporous copper plating technology, applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of heavy manual workload, poor electroplating, low efficiency, etc., to achieve good applicability and improve production efficiency , Improve the effect of conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

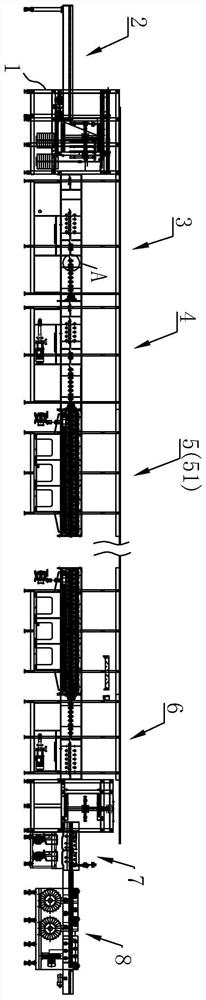

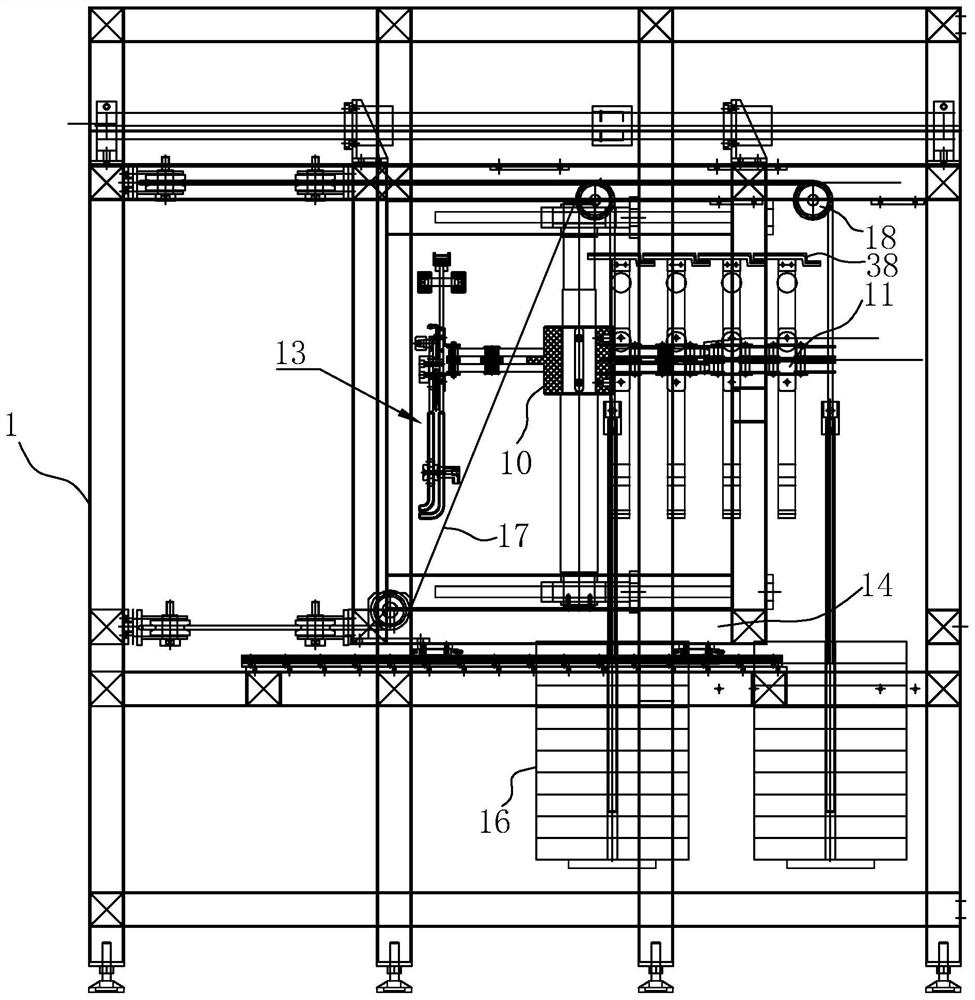

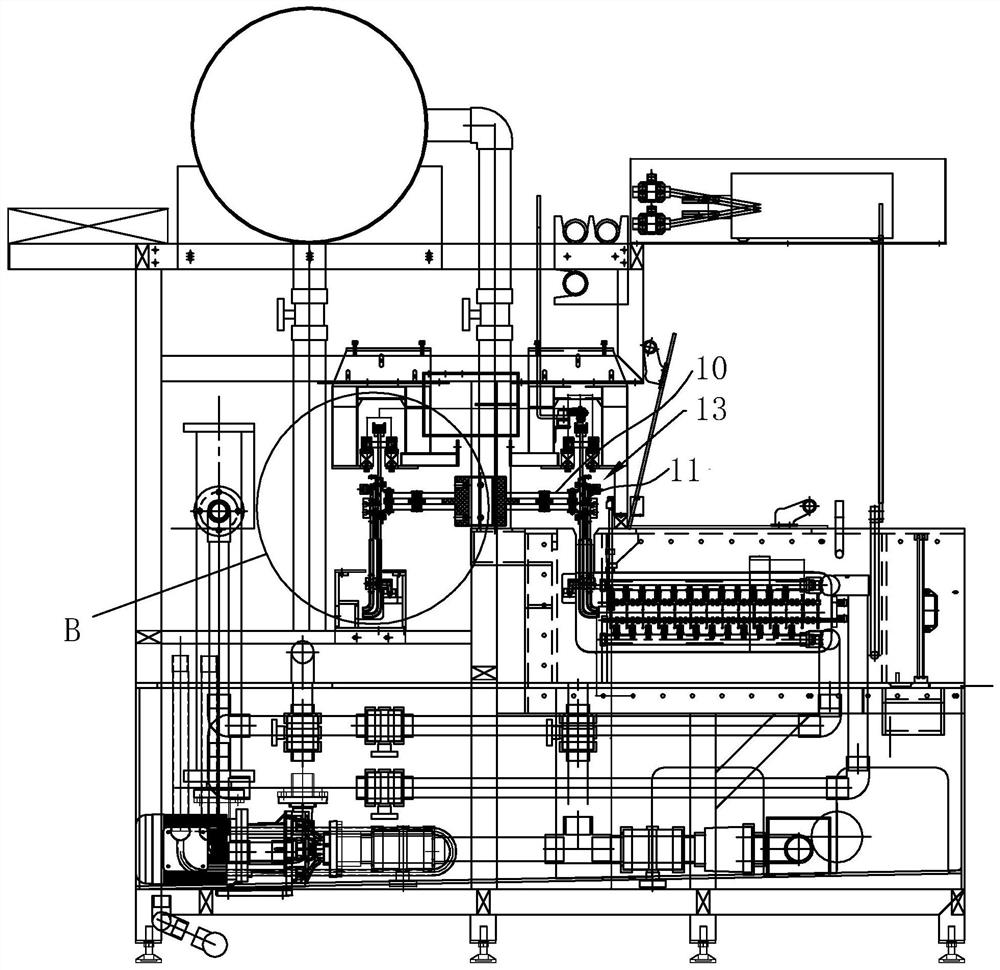

[0042] Embodiment 1: refer to figure 1 , is a kind of horizontal high aspect ratio circuit board microporous copper-plating and tin-plating equipment disclosed by the present invention, comprising a body 1, a feeding device 2, a first water washing device 3, and a pickling device arranged in sequence along the length direction of the body 1 4. Tin plating device 5 or copper plating device 51, second washing device 6, discharge device 7 and drying device 8, and the body 1 is provided with a conveyor for horizontally clamping the circuit board from the end of the feeding device 2 mechanism, the head end of the conveying mechanism is located between the feeding device 2 and the first washing device 3, and the end of the conveying mechanism is located between the second washing device 6 and the discharging device 7; thus the circuit board is conveyed horizontally in the feeding device 2 When coming over, the circuit board is firstly clamped horizontally by the conveying mechanism,...

Embodiment 2

[0051] Embodiment 2: refer to Figure 9 , is a horizontal high aspect ratio circuit board microhole copper plating and tinning equipment disclosed by the present invention. The difference between it and Embodiment 1 is that the structure of the upper clamp 20 at the clamping mechanism 13 is different. The upper clamp 20 in this embodiment The clamp 20 is L-shaped and includes a split upper body 45 and a lower body 46. A connecting sleeve 47 connecting the two is arranged between the upper body 45 and the lower body 46. Both ends of the connecting sleeve 47 are threadedly connected to the upper body 45 and the lower body 46 respectively. , one side of the connection sleeve 47 abuts against the lower clamp 21, so that the connection sleeve 47 can play a certain supporting role, keep the vertical parallelism between the upper clamp 20 and the lower clamp 21, and the lower end of the first spring 24 abuts against the connection sleeve 47 The upper end surface of the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com