Mining anchor withdrawing vehicle

A technology for mine use and anchor withdrawal, applied in the field of remote sensing and remote control, can solve the problems of low work efficiency, unsuitable mine environment, long time consumption, etc., to reduce the space required for operation, avoid personal safety threats, and improve operation safety. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

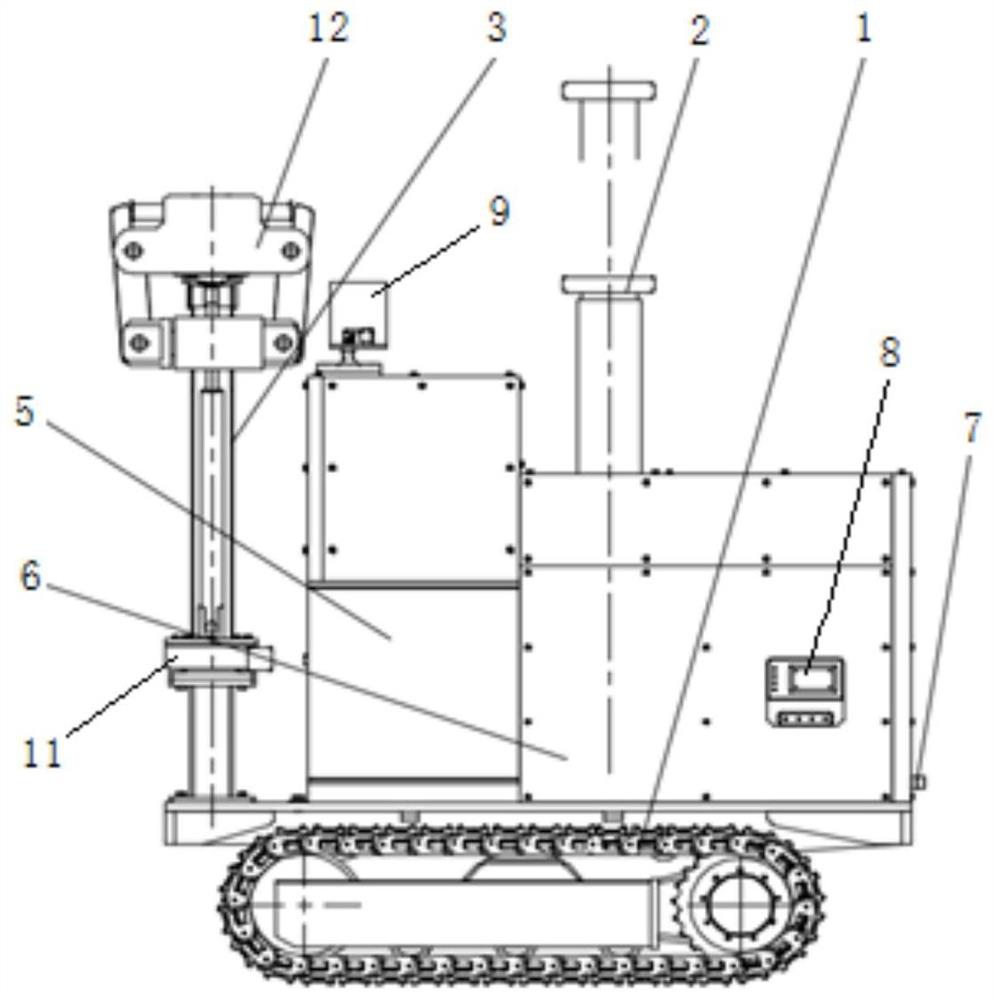

[0019] Viewed from the side of the anchor withdrawal vehicle, such as figure 1 As shown, the crawler belt 1 is installed at the bottom of the compartment 6, and the front half of the compartment is the oil supply system 5, which controls the action of each oil cylinder and motor through the oil pipe. and the operation screen of the anchor retractor 12, the remaining space of the compartment 6, flexibly adjust the position according to the needs of use, install the drive system, cooling system, communication system and alarm system, the sensor system 7 is installed on the periphery of the compartment 6, and the central control system The operation display panel of 8 can be installed on the side of the carriage, which is convenient for setting the parameters of the anchor car.

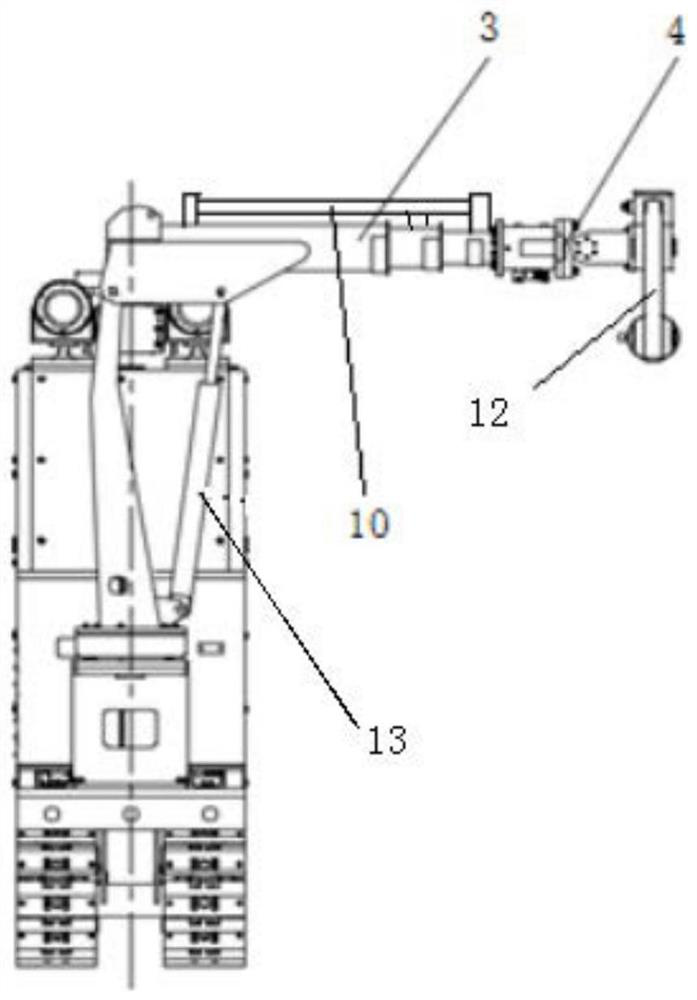

[0020] The mechanical arm is installed on the front of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com