Gradient ceramic column reinforced aluminum-based composite armor plate and preparation method

A technology for strengthening aluminum-based and ceramic columns, which is applied to the structure of armor plates, armor, protective equipment, etc., can solve the problems of weak integrity of composite armor plates and poor resistance to multiple strikes, and is beneficial to resist multiple strikes and improve The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

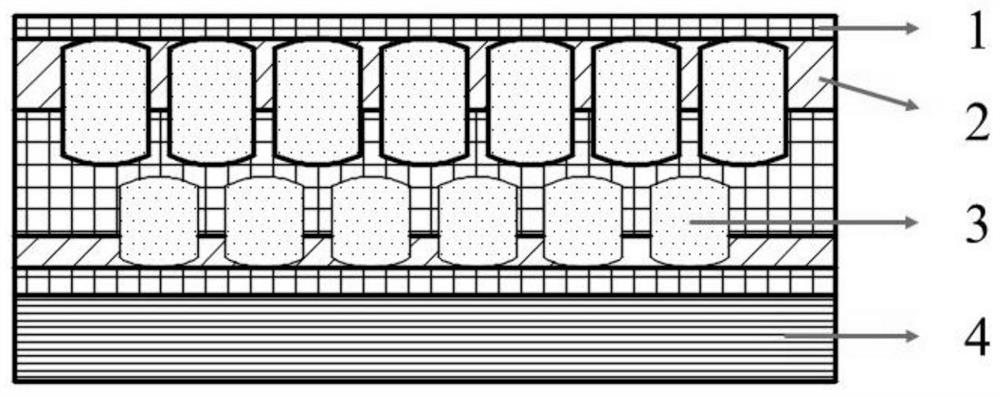

[0039] A method for preparing a gradient ceramic column reinforced aluminum-based composite armor plate, specifically according to the following steps:

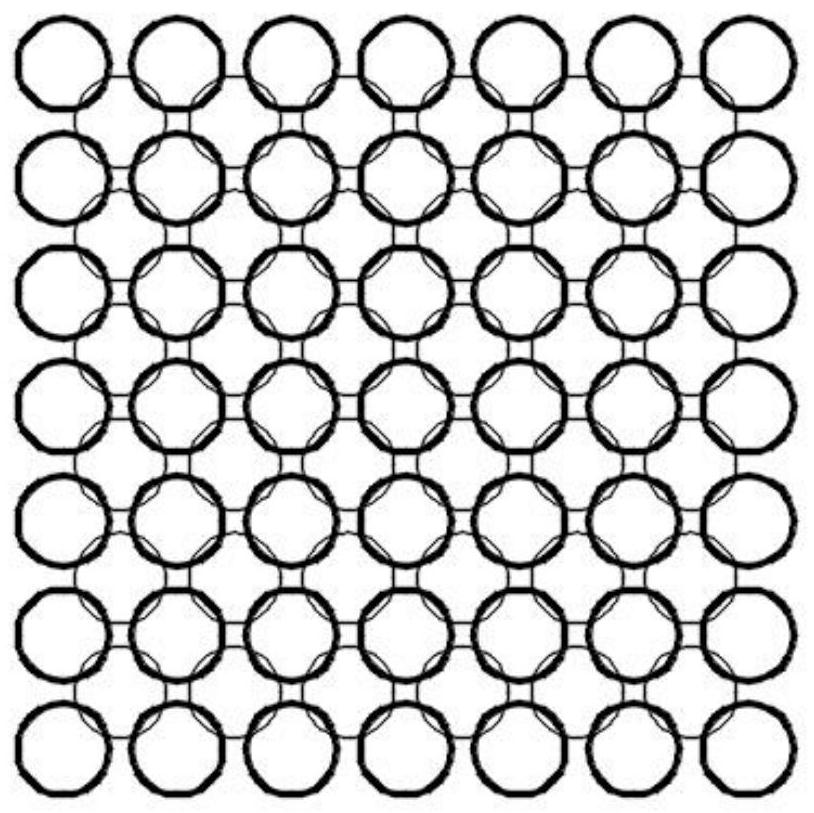

[0040] The plane size of the composite armor plate prepared in this example is 200mm×200mm, the diameter of the first layer of ceramic columns is 13mm, and the height is 15mm, and the diameter of the second layer of ceramic columns is 13mm, and the height is 15mm. The ceramic columns are arranged side by side, such as figure 2 As shown, the bottom plate is bonded.

[0041] A. Milling holes on 6061 aluminum alloy substrate: prepare a piece of 6061 aluminum alloy with a total thickness of 10mm, and mill out cylindrical flat-bottomed holes on both sides according to the specified plan. The distance is 13.2mm, and the centers of the holes of the ceramic pillars of the second layer are located at the line connecting the centers of the four holes of the ceramic pillars of the first layer.

[0042] B. Cleaning of ceramic column and...

Embodiment 2

[0049] A preparation method of a gradient ceramic column reinforced aluminum-based composite armor plate is specifically carried out according to the following steps:

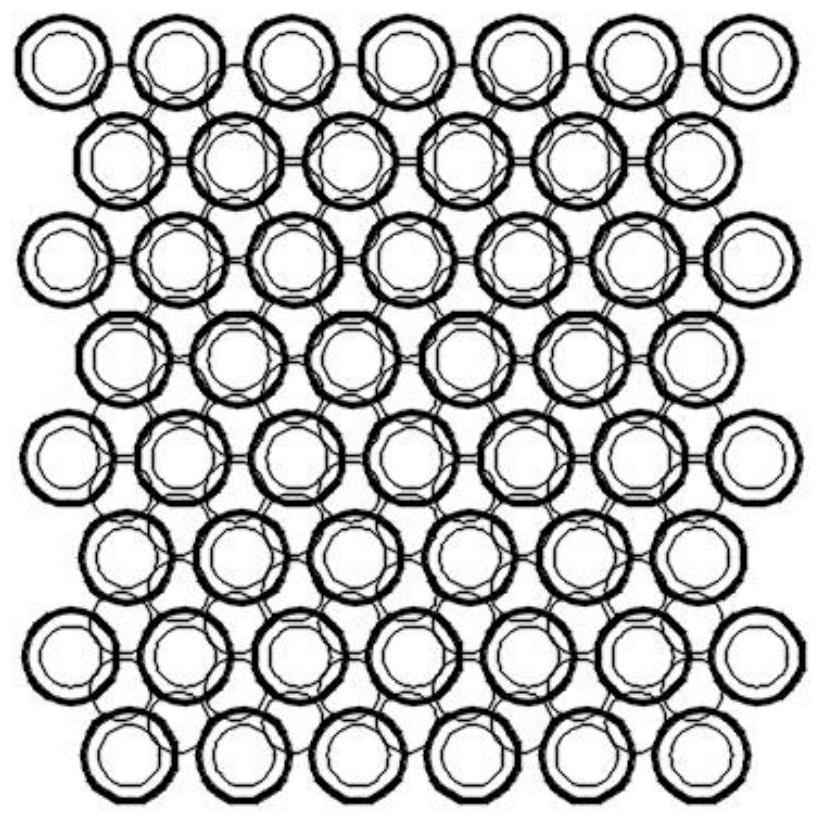

[0050] The plane size of the composite armor plate prepared in this example is 200mm×200mm, the first layer of ceramic columns has a diameter of 13mm and a height of 11.5mm, and the second layer of ceramic columns has a diameter of 13mm and a height of 11.5mm. The ceramic columns are arranged in a staggered arrangement, such as image 3 As shown, the bottom plate is bonded.

[0051] The thickness of the composite armor plate prepared according to the process of Example 1 is 27.2mm, and the surface density is 82.3kg / m 2 , the ceramic volume content is 63.65%; and then paste 14mm 6061 aluminum alloy plate on the bottom surface with epoxy resin, the total surface density of the composite armor is 119.5kg / m 2 . Anti-54 type 12.7mm piercing incendiary bomb vertical incidence, shooting distance 100m, average bulle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com