Squid-derived active peptide suckable jelly and preparation method thereof

A technology of active peptide and squid, which is applied in the field of food processing, can solve the problems that the added value of squid viscera has not been fully developed and utilized, the processing and utilization technology of squid viscera is backward, and it is perishable and deteriorated, so as to achieve good development and utilization potential and reduce the impact on the body. Harm, the effect of preventing cardiovascular disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Screening pretreatment methods to promote autolysis

[0021] Using the degree of hydrolysis and peptide yield as indicators, the best pretreatment methods and conditions are screened, and the specific steps are as follows:

[0022] (1) Collect fresh squid viscera, wash and filter to dry;

[0023] (2) adding deionized water according to a certain material-to-liquid ratio, and fully homogenizing with a tissue masher to obtain squid visceral homogenate;

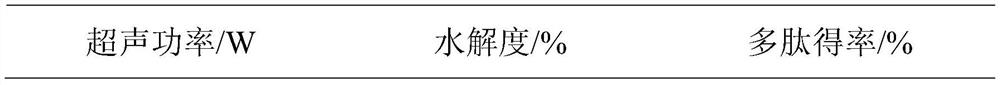

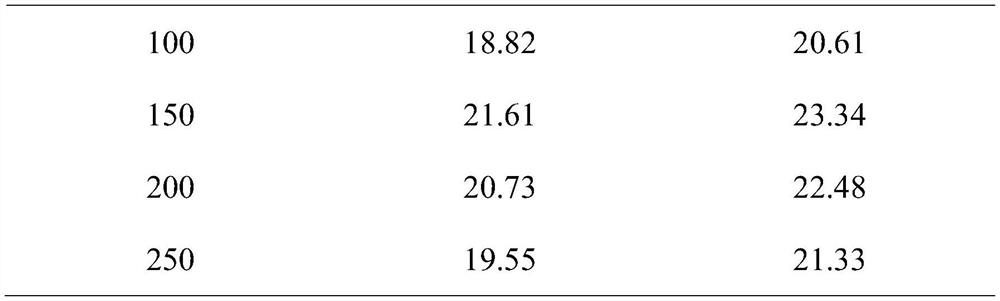

[0024] (3) pipette the homogenate in a beaker, adjust the pH, and carry out ultrasonic or ultraviolet irradiation treatment respectively to activate the autolytic enzyme in the squid viscera;

[0025] (4) The treated homogenate is placed in a water bath shaker for water bath treatment to bring into play the autolysis of the autolytic enzyme;

[0026] (5) The autolyzed product is subjected to an enzyme-inactivating treatment to obtain an autolyzed enzymatic hydrolyzate of squid viscera, which is separated afte...

Embodiment 2

[0054] Embodiment 2: Preparation of squid viscera self-solution

[0055] A method for preparing squid viscera from solution, comprising the following steps:

[0056] (1) Collect fresh squid viscera, wash and filter to dry;

[0057] (2) adding deionized water according to a certain material-to-liquid ratio, and fully homogenizing with a tissue masher to obtain squid visceral homogenate;

[0058] (3) Pipette the homogenate into a beaker, homogenize with a material-to-liquid ratio of 1:3, and then perform ultrasonic treatment, with an ultrasonic power of 150W and an ultrasonic time of 15 minutes;

[0059] (4) The treated homogenate is placed in a water bath shaker for water bath treatment, the conditions are: temperature 50°C, pH 3.5, time 6h, to activate the autolysis of the autolytic enzyme;

[0060] (5) The autolyzed product was subjected to enzyme-inactivating treatment to obtain the autolyzed enzymatic hydrolyzate of the squid viscera, which was separated after centrifugat...

Embodiment 3

[0061] Embodiment 3: Ultrafiltration

[0062]Pass the supernatant in Example 3 through ultrafiltration membranes with molecular weight cut-offs of 10KDa, 5KDa and 3KDa in sequence, collect the two components on and off the membrane, and obtain molecular weight cut-off ranges of >10KDa, 10KDa-5KDa, and 5KDa-3 KDa respectively And the four components <3KDa, freeze-dried at a vacuum degree of 0.12mbar and a temperature of -55°C for ≥24h, to obtain polypeptide powder of each component, to detect the antioxidant activity of each ultrafiltration component, and to measure the antioxidant activity The DPPH method is used.

[0063] Table 8 Polypeptide ultrafiltration classification results

[0064]

[0065] It can be seen from Table 8 that the separation and enrichment of the active components in the enzymatic hydrolyzate can be achieved after the enzymatic hydrolyzate is ultrafiltered by 10KDa, 5KDa and 3KDa filter membranes. The scavenging rate of active ingredients in the perme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com