Composite friction energy dissipation variable tension TiNi alloy wire self-resetting damper

A technology of frictional energy consumption and alloy wire, which is applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of not being able to adjust the energy consumption capacity and self-resetting capacity of the damper in real time, and achieve the effect of preventing damage and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

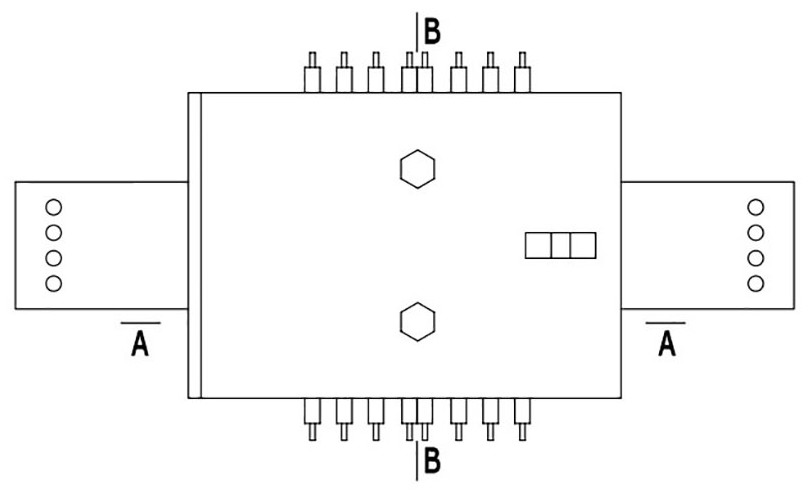

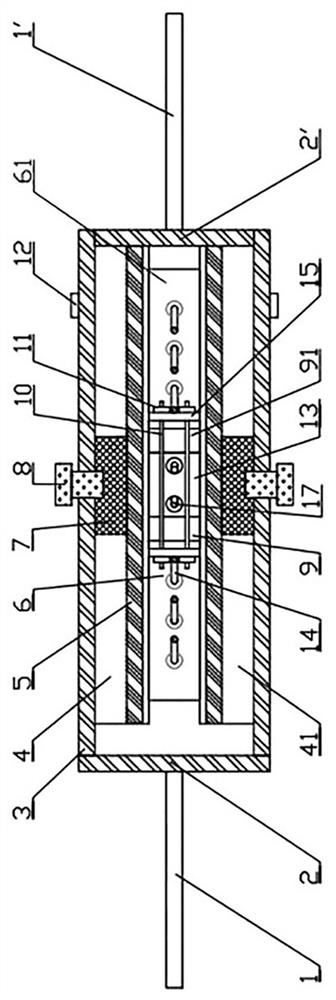

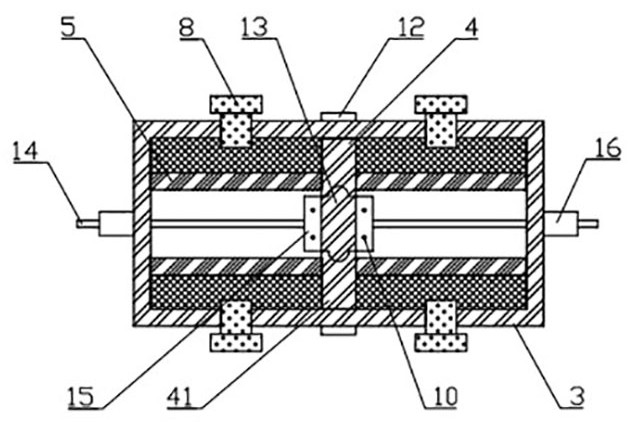

[0018] Embodiment 1: The present invention is a variable tension TiNi alloy wire self-resetting damper with composite frictional energy consumption, including 2 connectors 1, 2 end plates 2, restraining cylinder 3, 2 sliding rods 4, 4 pieces of friction Plate 5, 2 sliders 6, 4 friction blocks 7, 4 bolts 8, 2 piezoelectric ceramic drivers 9, 4 prestressed steel wires 10, 8 anchor bolts 11, 2 limit blocks, 6 groups of TiNi Alloy wire 14, 16 anchoring devices 16, 2 sets of ultra-high molecular weight polyethylene fibers 17; the main structure of the damper is a symmetrical structure up and down.

Embodiment 2

[0019] Embodiment 2: In this embodiment, multiple groups of TiNi alloy wires 14 and ultra-high molecular weight polyethylene fibers 17 pass through the connection holes and anchor holes and are fastened on both sides of the restraint cylinder 3 by the anchor device 16. Because the connection holes and the restraint cylinder are anchored There is a certain dislocation of the holes, so a flexible "bowstring" system will be formed. When vibration occurs, the movement of the up and down sliding rods to the left or right will cause the TiNi alloy wire to be pulled and consume energy. At the same time, the left and right movement of the upper and lower sliding rods will drive the friction steel plate to move and generate frictional energy consumption with the friction block. The friction force between the friction steel plate and the friction block can be adjusted by bolts.

Embodiment 3

[0020] Embodiment 3: Driven by the right connecting piece 1´, the upper and lower sliding rods can slide in the restraint cylinder 3, but at the same time, the displacement is limited by the limit block 12, and the limited displacement is equal to the "bowstring" of the TiNi alloy wire in the restraint cylinder 3 Maximum displacement; the anchor hole 31 of the constraint cylinder 3 and the connecting hole 62 of the slider and the block are rounded to reduce the friction between the TiNi alloy wire 14 and the ultra-high molecular weight polyethylene fiber 17 and the hole wall, prolonging the service life of the damper; The TiNi alloy wire 14 is a superelastic alloy wire in an austenite state at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com