External heating type solid hydrogen storage system and hydrogen charging and discharging method thereof

A solid-state hydrogen storage technology, applied in the field of hydrogen energy, can solve the problems of low thermal conductivity of hydrogenation products, unfavorable hydrogen charging and discharging reactions, and slow start-up of equipment, and achieve the effects of simple structure, reduced start-up time, and increased filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

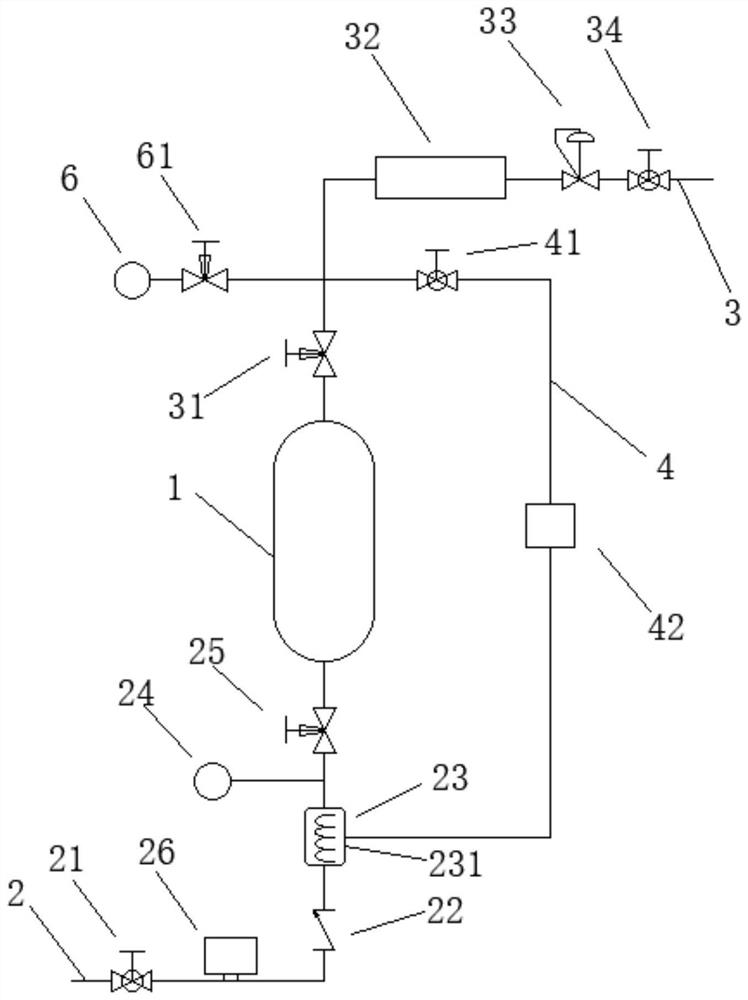

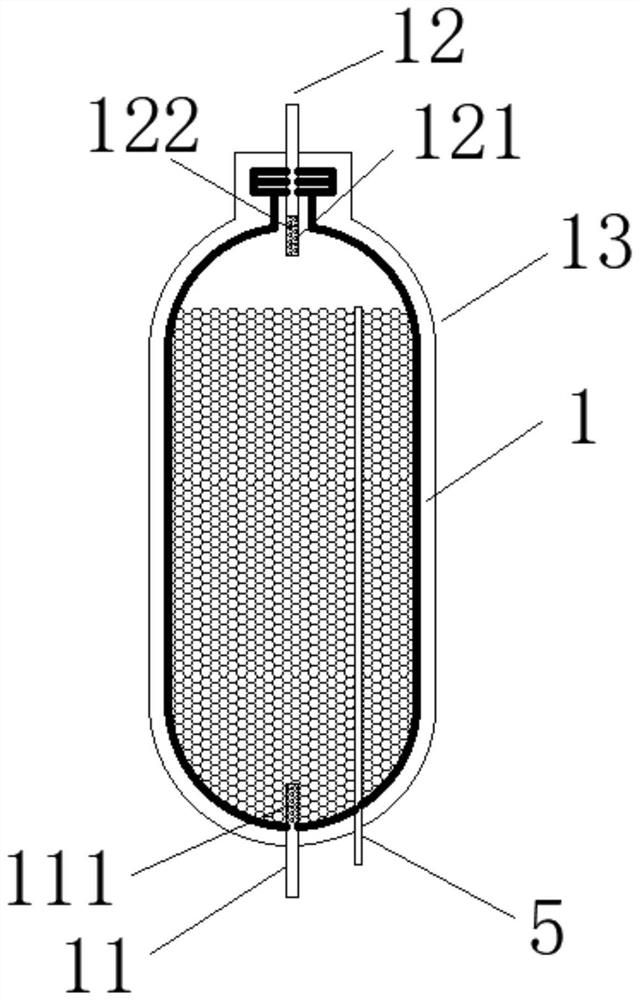

[0019] Such as figure 1 and 2 As shown, an externally heated solid-state hydrogen storage system of the present invention includes a hydrogen storage tank 1, an air inlet pipe 2, an air outlet pipe 3 and a circulation pipe 4. The hydrogen storage tank 1 is filled with a magnesium-based hydrogen storage alloy, and the hydrogen storage tank 1 is provided with at least one temperature sensor sleeve 5 along the axial direction, and a plurality of first temperature sensors (not shown in the figure) are installed in the temperature sensor sleeve 5 for real-time monitoring of the temperature at different positions in the hydrogen storage tank 1 The air inlet pipe 2 and the air outlet pipe 3 are respectively connected with the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com