High-temperature-storage-resistant oil-based lithium ion battery diaphragm and preparation method thereof

A high temperature resistant and diaphragm technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as capacity reduction and active material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

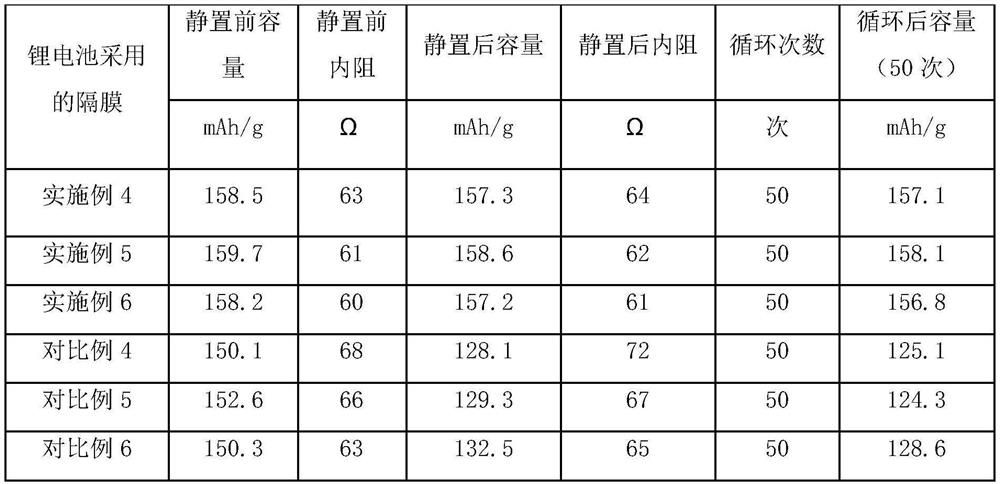

Examples

Embodiment 1

[0025] A method for preparing a high-temperature-resistant storage diaphragm slurry, comprising: putting an organic solvent and PVDF into a stirring tank, stirring at a speed of 1450 rpm for 80 minutes, adding a water removal additive, stirring at a speed of 1500 rpm for 35 minutes until uniform, adding high-temperature ingredients For the membrane agent, stir at a speed of 1500rpm for 50min until uniform, then add the optimizer, stir at a speed of 1500rpm for 30min until uniform, and obtain a high-temperature-resistant storage diaphragm slurry, wherein the organic solvent is DMAC, and the water-removing additive is alkyl phosphoric anhydride. The high-temperature film-forming agent is methylene disulfonate, and the optimizing agent is fluoroboric acid ester. The ratio of organic solvent, PVDF, water-removing additive, high-temperature film-forming agent and optimizing agent is 13:2 in parts by mass. :0.05:0.08:0.08.

Embodiment 2

[0027] A method for preparing a high-temperature-resistant storage diaphragm slurry, comprising: putting an organic solvent and PVDF into a stirring tank, stirring at a speed of 1550 rpm for 90 minutes, adding a water-removing additive, stirring at a speed of 1500 rpm for 40 minutes until uniform, adding high-temperature ingredients Membrane, stir at a speed of 1500rpm for 60min until uniform, then add the optimizer, stir at a speed of 1500rpm for 40min until uniform, and obtain a high-temperature storage diaphragm slurry, wherein the organic solvent is DMF, and the water-removing additive is alkyl phosphoric anhydride. The high-temperature film-forming agent is methylene disulfonate, and the optimizing agent is fluoroboric acid ester. The ratio of organic solvent, PVDF, water-removing additive, high-temperature film-forming agent and optimizing agent is 18:2.8 in parts by mass. :0.09:0.15:0.2.

Embodiment 3

[0029] A method for preparing a high-temperature-resistant storage diaphragm slurry, comprising: putting an organic solvent and PVDF into a stirring tank, stirring at a speed of 1650 rpm for 100 minutes, adding a water removal additive, stirring at a speed of 1500 rpm for 45 minutes until uniform, adding high-temperature ingredients The membrane agent was stirred at a speed of 1500rpm for 70min until uniform, then the optimizer was added and stirred at a speed of 1500rpm for 50min until uniform to obtain a high-temperature-resistant storage diaphragm slurry, wherein the organic solvent was DMAC, and the water-removing additive was alkyl phosphoric anhydride. The high-temperature film-forming agent is 4-methylethylene sulfite, and the optimizer is fluoroboric acid ester. The ratio of organic solvent, PVDF, water-removing additive, high-temperature film-former and optimizer is 22 in parts by mass. :3.2:0.12:0.23:0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com