Treatment system comprising wood-based organic material, use thereof in wastewater treatment, and method for removing dissolved organic compounds from wastewater

A technology for processing systems and organic materials, applied in the field of removing COD and removing dissolved organic compounds, and can solve problems such as ash formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] The wastewater used in the following reference examples and application examples 1-5 originated from the manufacture of bleached softwood kraft pulp, and samples were collected after wastewater biological treatment. Precipitation of organic soluble compounds occurred as described in more detail in the Examples below.

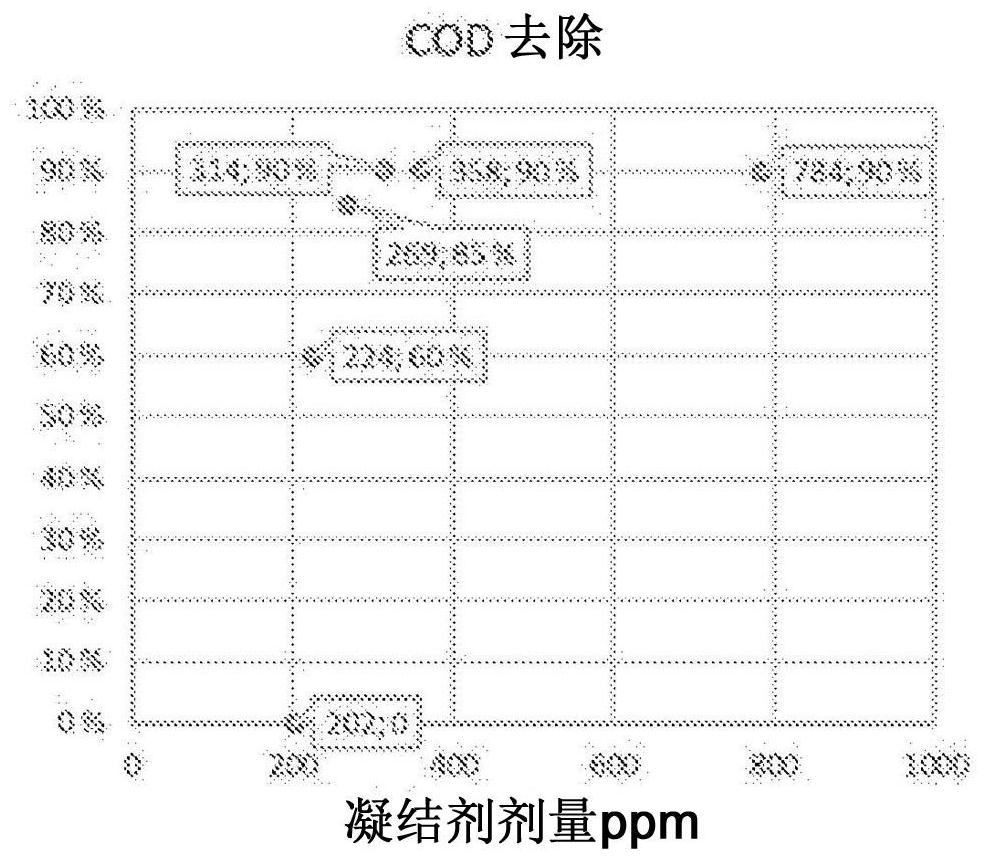

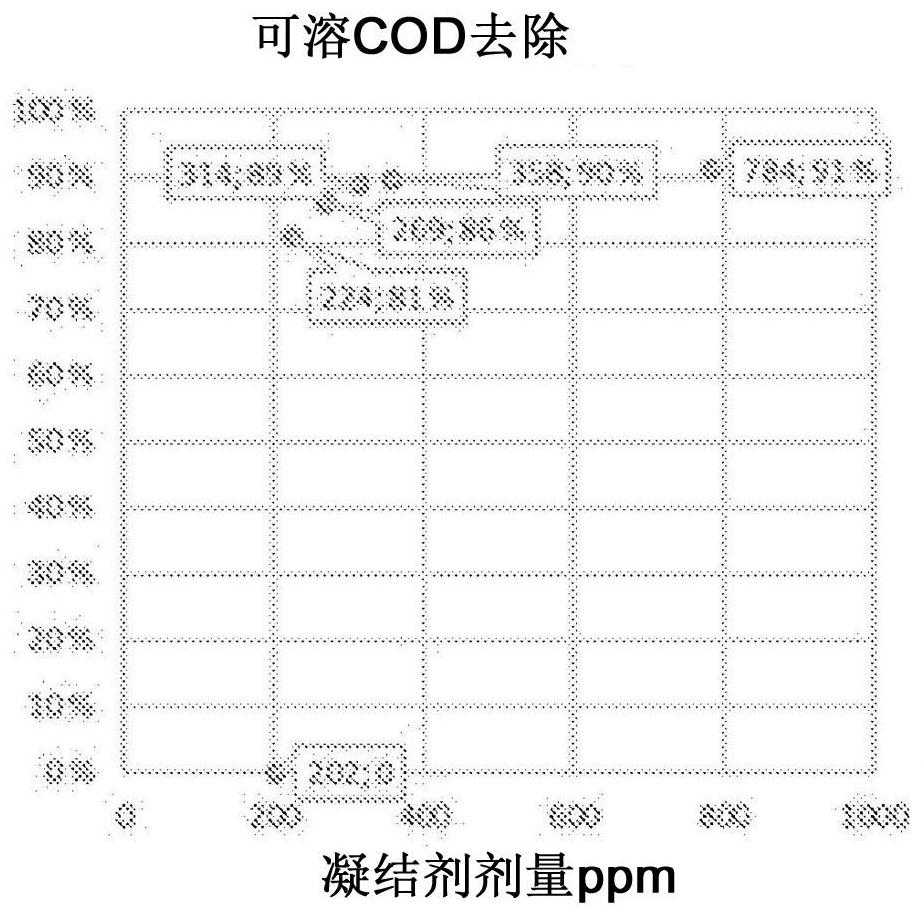

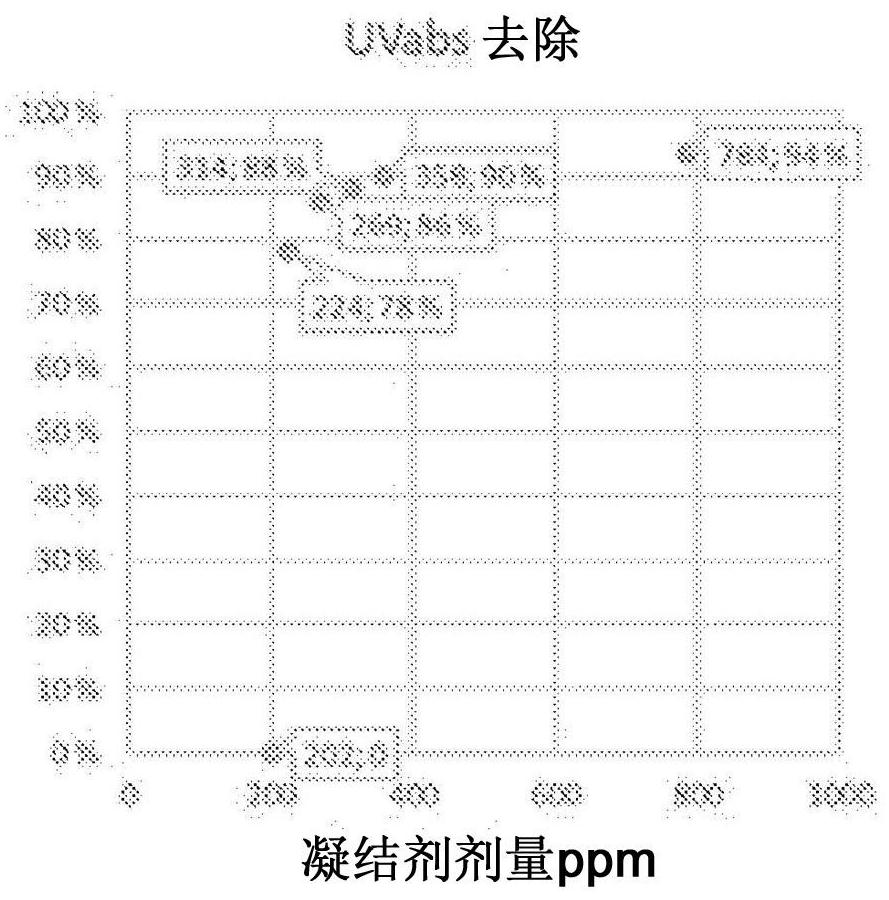

[0071] Reference example: COD removal efficiency in waste water when using ferric sulfate coagulant Ferix-3 alone

[0072] The COD removal efficiency of wastewater using ferric sulfate coagulant Ferix-3 (Kemira Oyj) alone is as follows figure 1 shown in . figure 1 . Ferix-3 coagulant alone (dose of the product is 784ppm) tested without pH adjustment and with pH adjustment (dose of the product = 202, 224, 269, 314 and 358ppm; pH = 4) COD removal efficiency. Such as figure 1 It was shown that 90% COD removal could be achieved without pH adjustment at the coagulant dosage of 784 ppm. When the pH value of wastewater was adjusted to 4, when the dosage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com