Aluminum material anodic oxidation dyeing device

An anodizing and dyeing device technology, applied in chemical instruments and methods, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve problems such as pH drop, aluminum or aluminum alloy workpieces are prone to shaking, and affect the dyeing effect of workpieces. achieve an effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

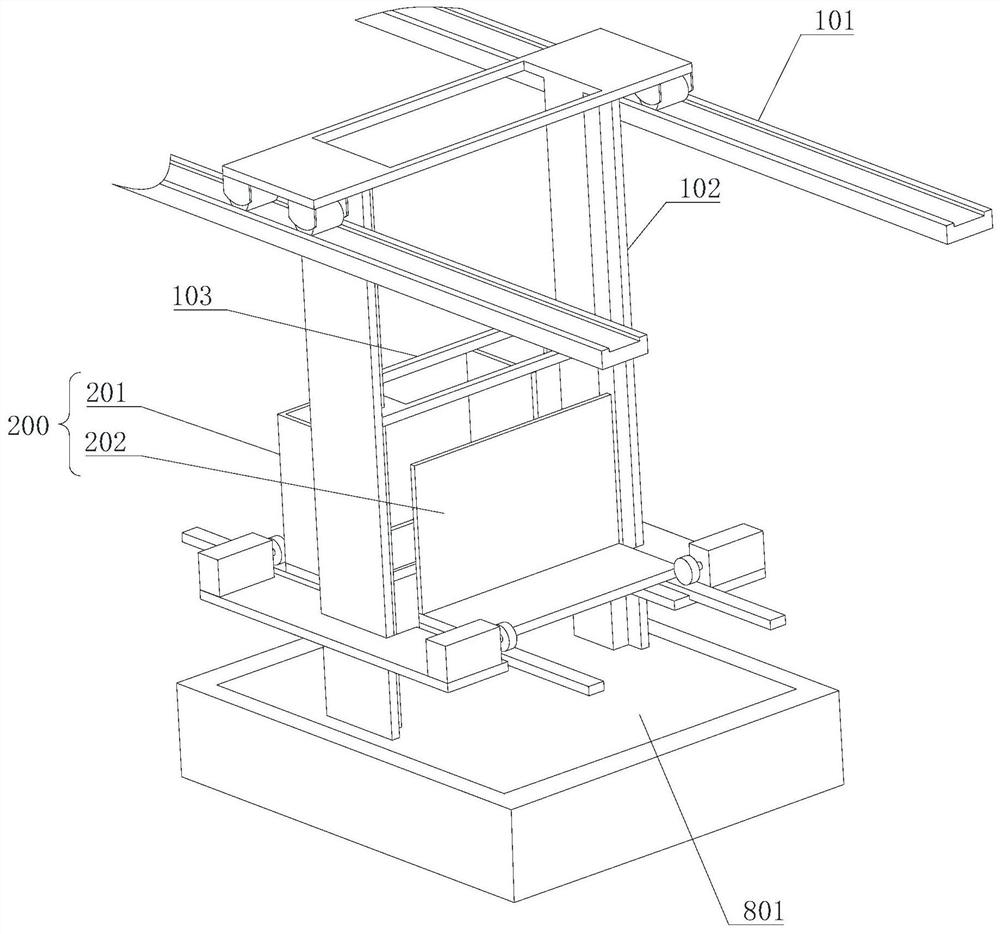

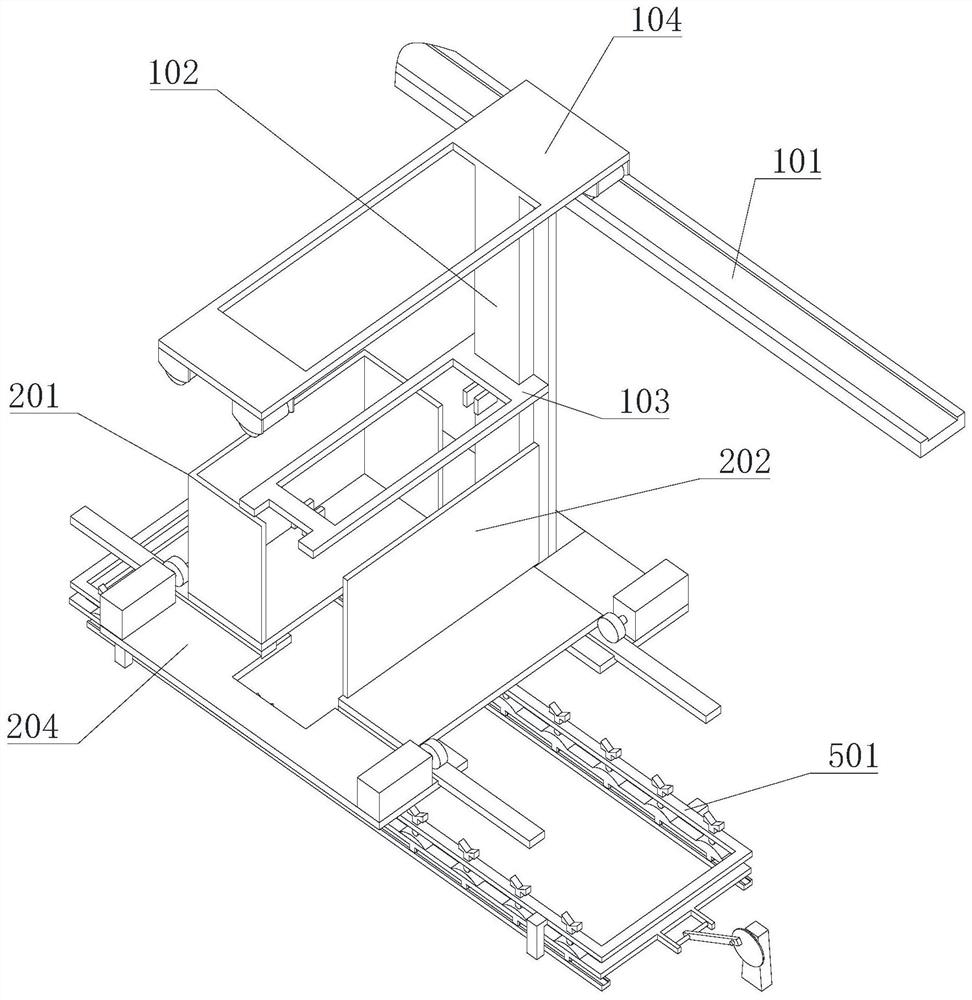

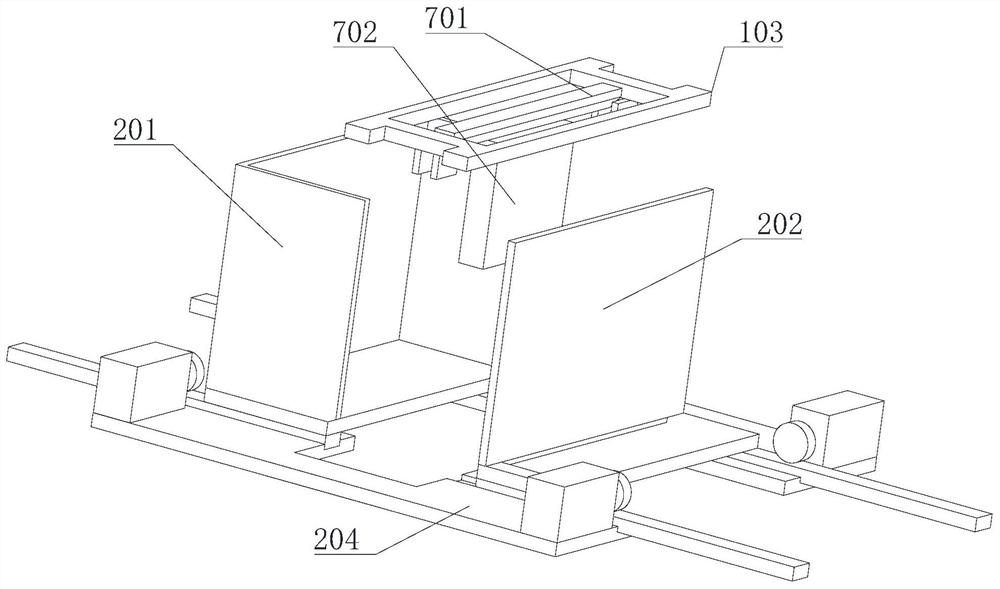

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present application, the specific implementation manners of the present application will now be described with reference to the accompanying drawings. In each figure, the same reference numerals represent components with the same structure or similar structure but the same function.

[0042] In this article, "schematic" means "serving as an example, example or illustration", and any illustration or implementation described as "schematic" should not be interpreted as a more preferred or more advantageous Technical solutions.

[0043] In order to keep the drawings concise, each drawing only schematically shows the parts relevant to the present application, and they do not represent the actual structure of the product. In addition, in order to make the drawings concise and easy to understand, in some drawings, only one of the components having the same structure or function is sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com