Polymer, monomer, coating composition comprising same, organic light emitting diode using same, and method for manufacturing organic light emitting diode by using same

A technology of organic light-emitting devices and polymers, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of concentration gradient change, high device, and defective formation, and achieve high glass transition temperature, Improvement of light efficiency and improvement of life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

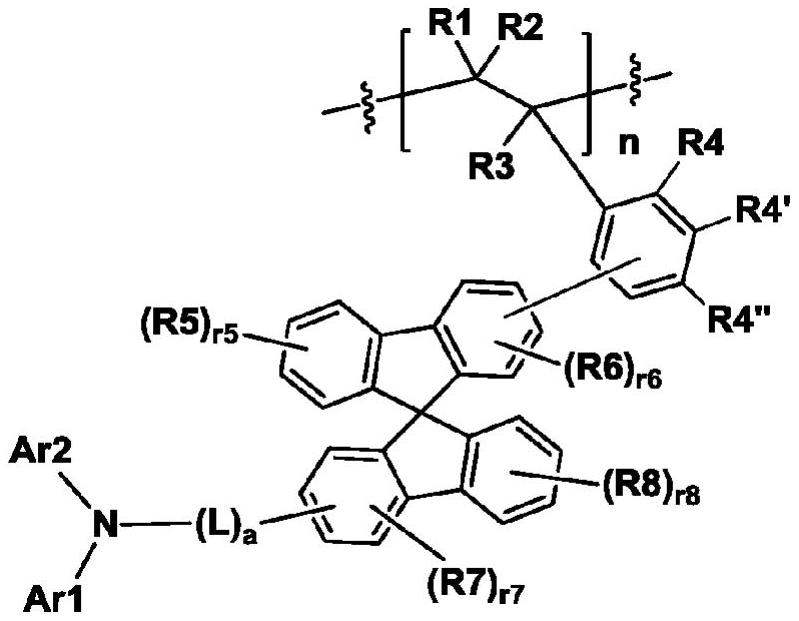

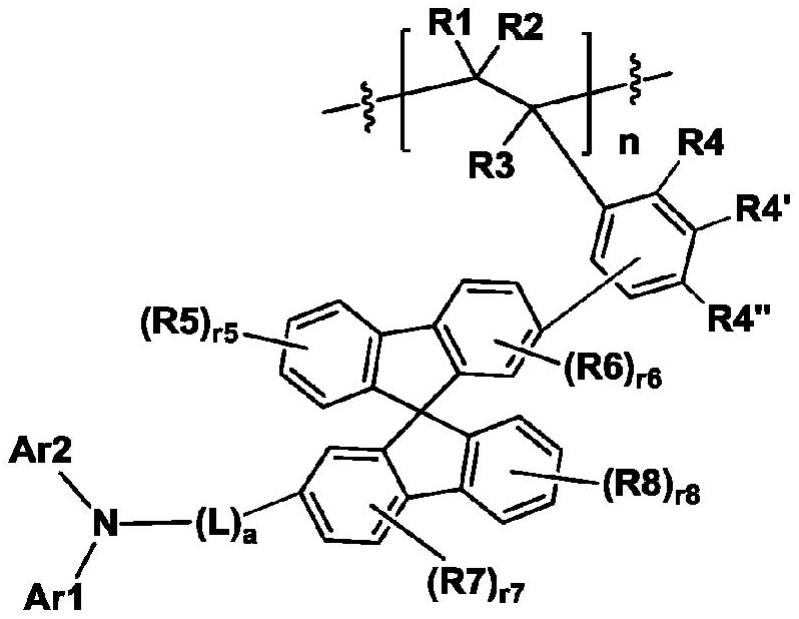

Method used

Image

Examples

Embodiment approach

[0264] Hereinafter, the specification will be described in detail with reference to the embodiments to specifically describe the specification. However, the embodiments according to the present specification can be modified into various forms, and the scope of the present specification should not be construed as being limited to the embodiments described below. The embodiments of this specification are provided to more fully describe this specification to those of ordinary skill in the art.

[0265] Synthesis of Monomer 1

[0266]

[0267] Synthesis of compound 3-A

[0268]Compound 1-A (50 g, 105.4 mmol, 1 eq) and compound 2-A (31.2 g, 211 mmol, 2 eq) were dissolved in tetrahydrofuran (THF) (300 g), and stirred in a silicone bath at 80° C. for 10 minutes . K dissolved in water (300 mL) was added dropwise thereto 2 CO 3 (37.89 g, 274 mmol, 2.6 eq) for 10 min. Pd catalyst (3.66 g, 3.2 mmol, 0.03 equiv) was introduced thereto under reflux. The resultant was stirred fo...

Embodiment 1

[0359] A glass substrate coated with indium tin oxide (ITO) with a thickness of 150 nm as a thin film was placed in distilled water in which a detergent was dissolved and ultrasonically cleaned. Herein, a product of Fischer Co. was used as a cleaning agent, and distilled water filtered twice with a filter manufactured by Millipore Co. was used as distilled water. After cleaning the ITO for 30 minutes, ultrasonic cleaning was repeated twice for 10 minutes using distilled water. After completion of rinsing with distilled water, the substrate was ultrasonically cleaned with a solvent of isopropanol and acetone, then dried, rinsed for 5 minutes, and then transferred to a glove box.

[0360]On the transparent ITO electrode, spin-coat (4000rpm) by making compound A and compound B (the weight ratio is 8:2) dissolve the coating composition that obtains in cyclohexanone with 2 weight / volume %, and at 230 ℃ Heat treatment (curing) was performed for 30 minutes to form a hole injection l...

Embodiment 2 to 12

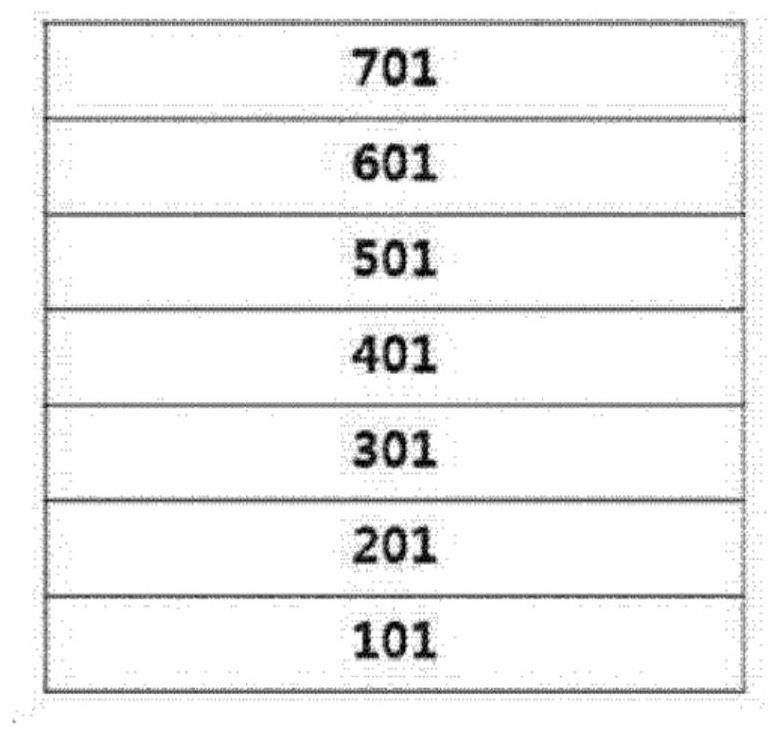

[0364] Organic light-emitting devices of Examples 2 to 12 were fabricated in the same manner as in Example 1 except that the polymers of Table 2 below were used instead of Polymer 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com