Method for determining influence of antifreeze agent on quality and nutrition change of dough

A method to determine the technology of antifreeze, which is applied in the treatment of dough, baked food with modified ingredients, baking, etc., to achieve the effects of extending shelf life, inhibiting protein oxidation and deformation, and improving water retention and gel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

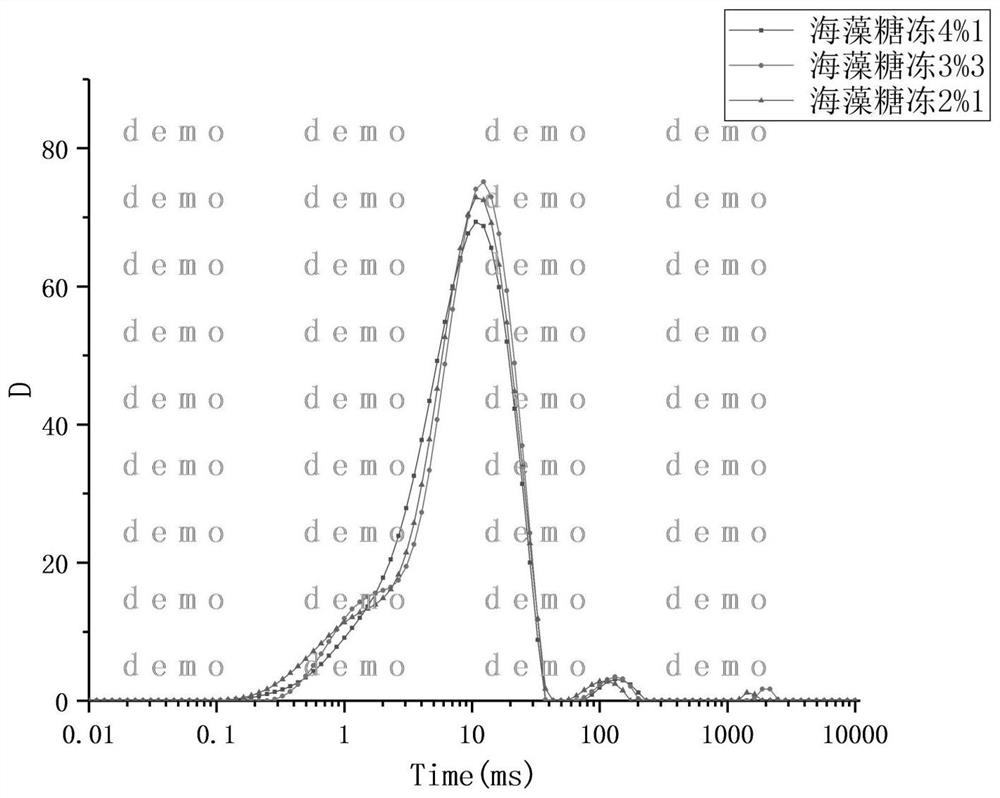

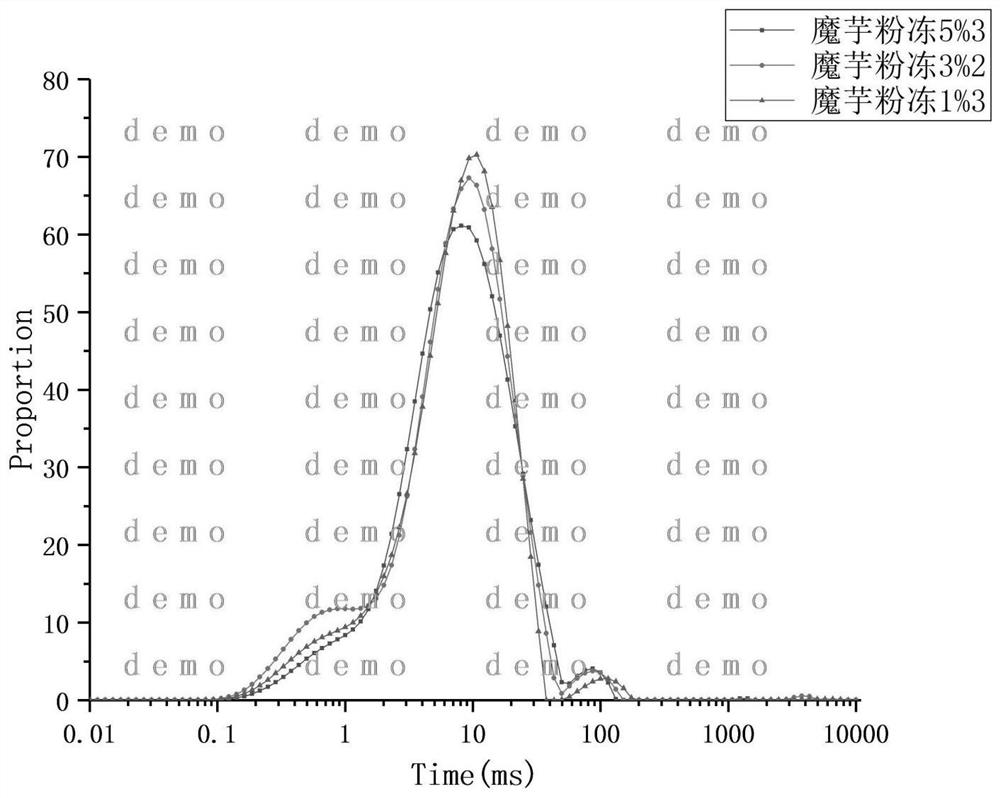

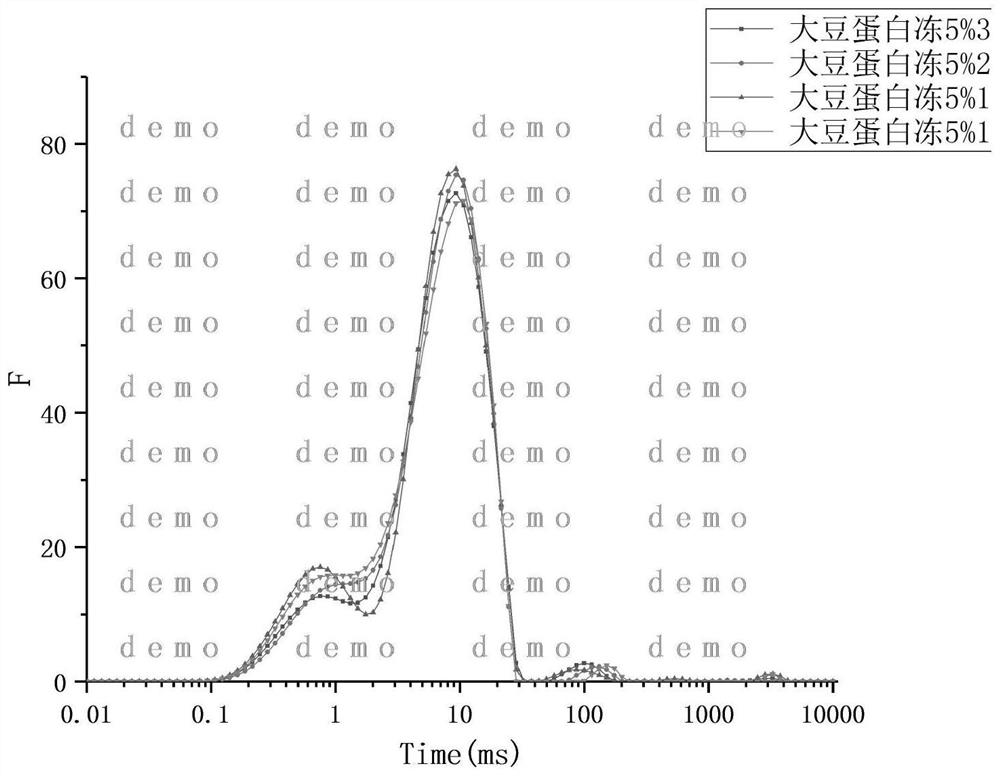

Embodiment 1

[0039] A method for determining the impact of antifreeze on dough quality and nutritional changes, wherein the antifreeze includes the following raw materials by weight: trehalose 18g, konjac flour 18g, soybean protein powder 12g, Vc 12g, bone protein hydrolyzate 10g, low acyl knot Cold gum 10g, sodium lactate 8g, sodium citrate 8g, modified starch 6g, gluten 6g, xanthan gum 5g and sorbitol 5g.

Embodiment 2

[0041] A method for determining the impact of antifreeze agents on dough quality and nutritional changes, wherein the antifreeze agents include the following raw materials by weight: trehalose 15g, konjac flour 20g, soybean protein powder 10g, Vc 15g, bone protein hydrolyzate 8g, low acyl knot Cold gum 12g, sodium lactate 6g, sodium citrate 9g, modified starch 5g, gluten 10g, xanthan gum 5g and sorbitol 10g.

Embodiment 3

[0043] A method for determining the impact of antifreeze agents on dough quality and nutritional changes, wherein the antifreeze agents include the following raw materials by weight: trehalose 20g, konjac flour 15g, soybean protein powder 15g, Vc 10g, bone protein hydrolyzate 12g, low acyl knot Cold gum 8g, sodium lactate 9g, sodium citrate 6g, modified starch 10g, gluten 5g, xanthan gum 10g and sorbitol 5g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com