Glycyrrhiza glabra leaf extract for improving quality of cold-stored pork products and frozen-stored pork products and preparation method of glycyrrhiza glabra leaf extract

The technology of extract and licorice leaf is applied to the licorice leaf extract and its preparation for improving the quality of refrigerated and frozen pork products. Reduce the edible quality, nutritional value and limited storage time of pork and its products, and achieve the effects of no odor, strong antioxidant activity, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of licorice leaf extract comprises the following steps:

[0033] Glycyrrhiza glabra leaves were washed and dried and crushed through a 60-mesh sieve, 80% ethanol (v / v) was added in a proportion of 10 times by weight, heated and kept in a slightly boiling state for reflux extraction for 2 hours, repeated extraction twice, combined extracts, centrifuged at 4000rpm, Filter the supernatant, and concentrate the supernatant under reduced pressure at 50°C to a paste; dilute the concentrated extract with distilled water to make the total flavonoid concentration of the solution reach 5 mg / mL, and perform pretreated XAD-16 macroporous resin column chromatography Column, using 0-50% (v / v) ethanol-distilled water gradient elution, collecting 50% ethanol (v / v) eluate, concentrating under reduced pressure to remove ethanol, and freeze-drying to obtain licorice leaf extract.

[0034] The obtained licorice leaf extract is brown-yellow powder with a sweet taste an...

Embodiment 2

[0036] Pork suet was purchased from Guangzhou Nansha Farmer's Market, boiled and filtered to remove residues to obtain experimental lard, and accurately weighed 3g of lard in each reaction tube.

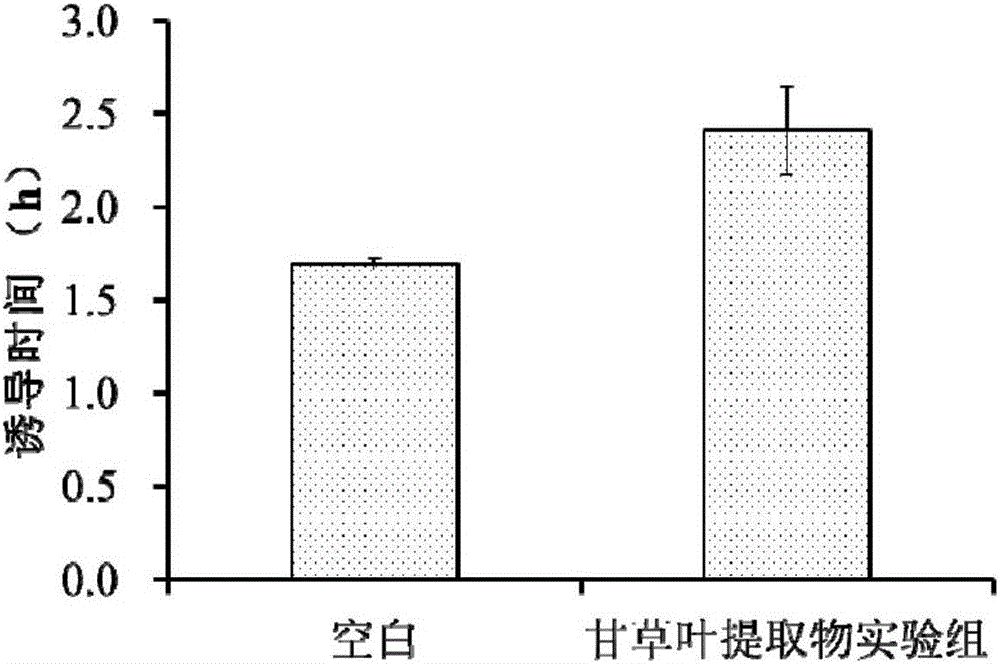

[0037] The licorice leaf extract of Example 1 was dissolved (dispersed) in absolute ethanol, added to each reaction tube at a mass fraction of 0.05%, and assisted by ultrasonic treatment for 10 min to make it evenly mixed. Adding the licorice leaf extract and the fat oxidation induction time of the blank group lard at ℃, the air flow rate is 20L / h, the experimental results are as follows figure 1 shown.

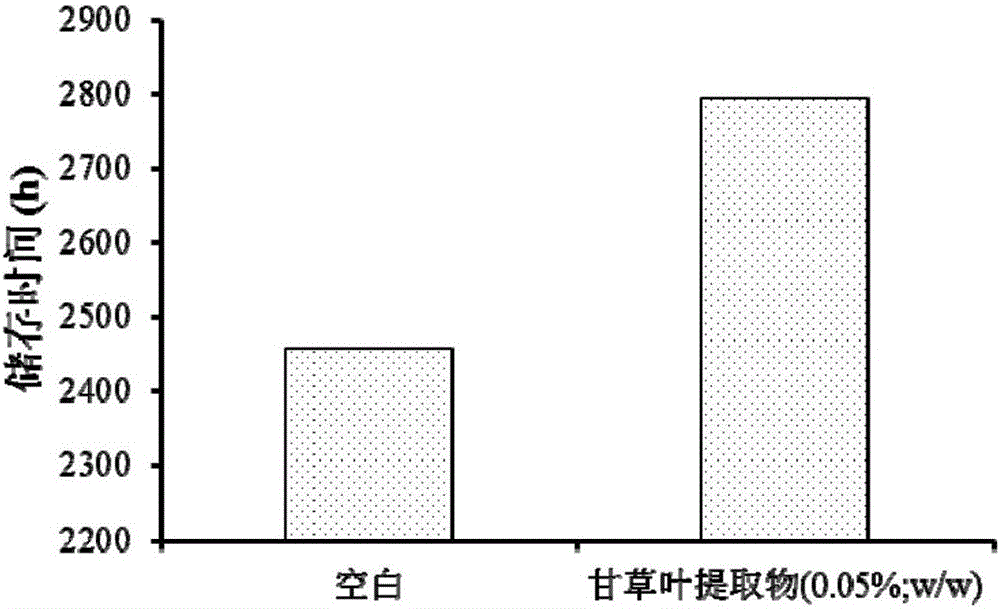

[0038] At the same time, the inhibitory effect of 0.05% licorice leaf extract on the oxidation of lard was investigated at 100°C, 110°C, 120°C and 130°C, and the shelf life was calculated by extrapolation (storage at 20°C).

[0039] Experimental results:

[0040] like figure 1 As shown, compared with the blank group, the oxidation induction time of lard added with licorice leaf e...

Embodiment 3

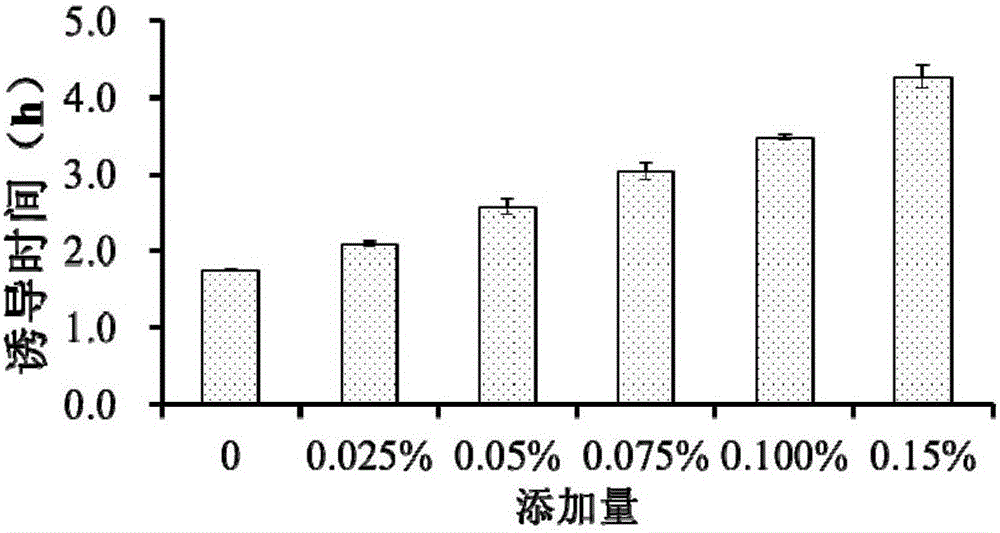

[0043]Pork suet was purchased from Guangzhou Nansha farmer's market, boiled and filtered to remove the residue to obtain lard for experimentation, accurately weighed 3g lard in each reaction tube, and studied the effect of different additions of licorice leaf extract on lard according to the method of Example 2. Inhibition of lipid oxidation. Dissolve (disperse) the licorice leaf extract in absolute ethanol, add it to each reaction tube at a mass fraction of 0.025%, 0.05%, 0.075%, 0.100% and 0.15%, and ultrasonically assist it for 10 minutes to mix it evenly, and use oil oxidation Rancimat was used to compare the oil oxidation induction time of five different addition groups of licorice leaf extract at 120°C and the blank group lard, the air flow rate was 20L / h, and the experimental results were as follows: image 3 shown.

[0044] image 3 It was shown that with the increase of the addition amount, the induction time of lard oxidation continued to prolong, and the licorice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com