Polymeric micellar coating for sequential delivery of immunomodulatory factors on nanorod arrayed surface and preparation method and application

An immunoregulatory factor, polymer micelle technology, applied in coating, medical science, prosthesis and other directions, can solve problems such as insufficient osseointegration performance, and achieve the effect of stable process, simple process and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

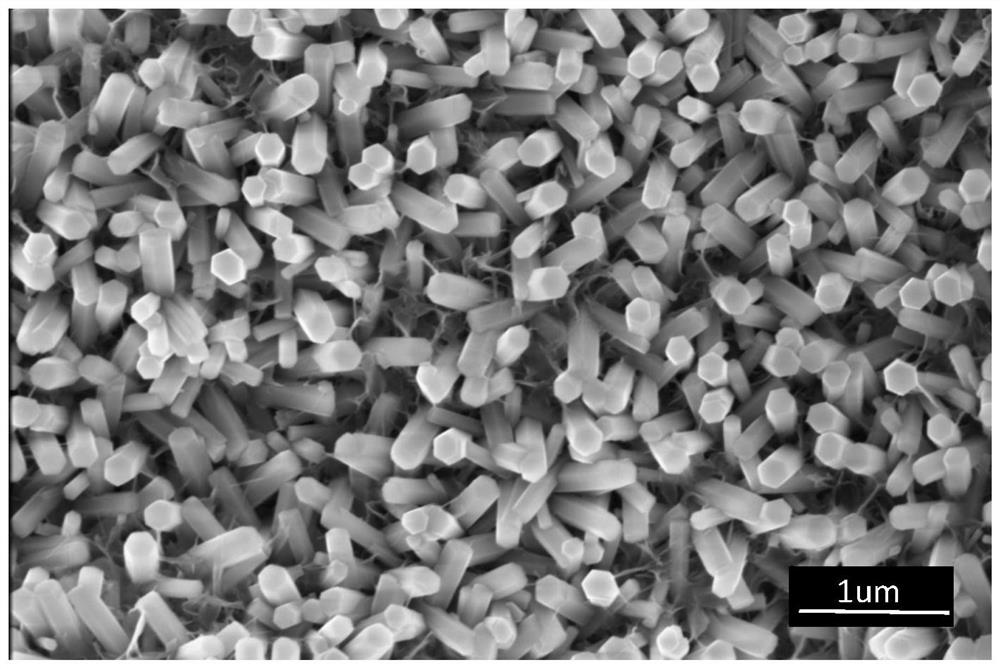

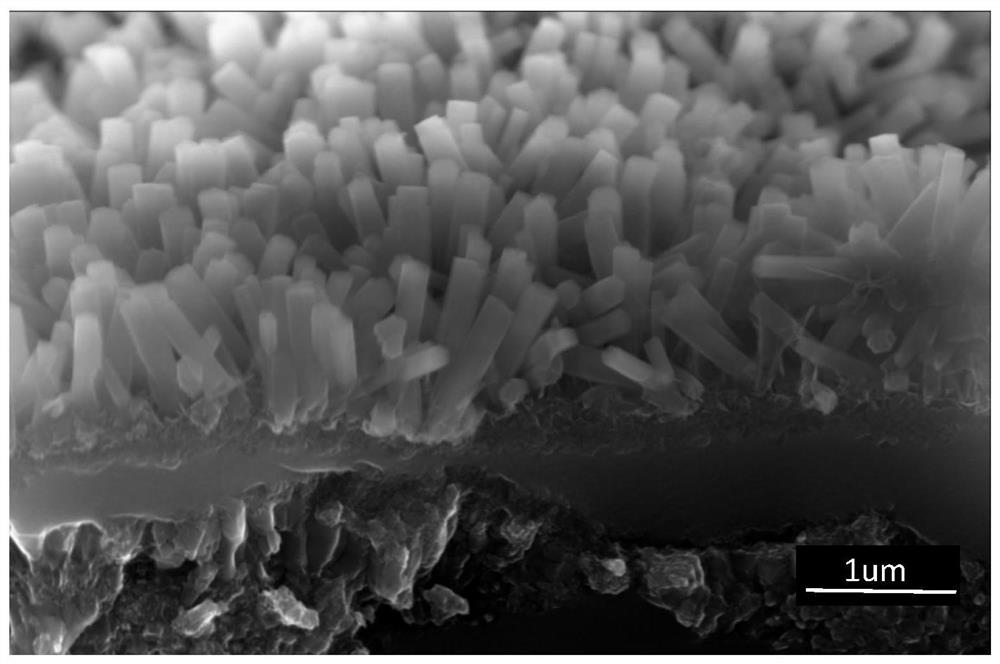

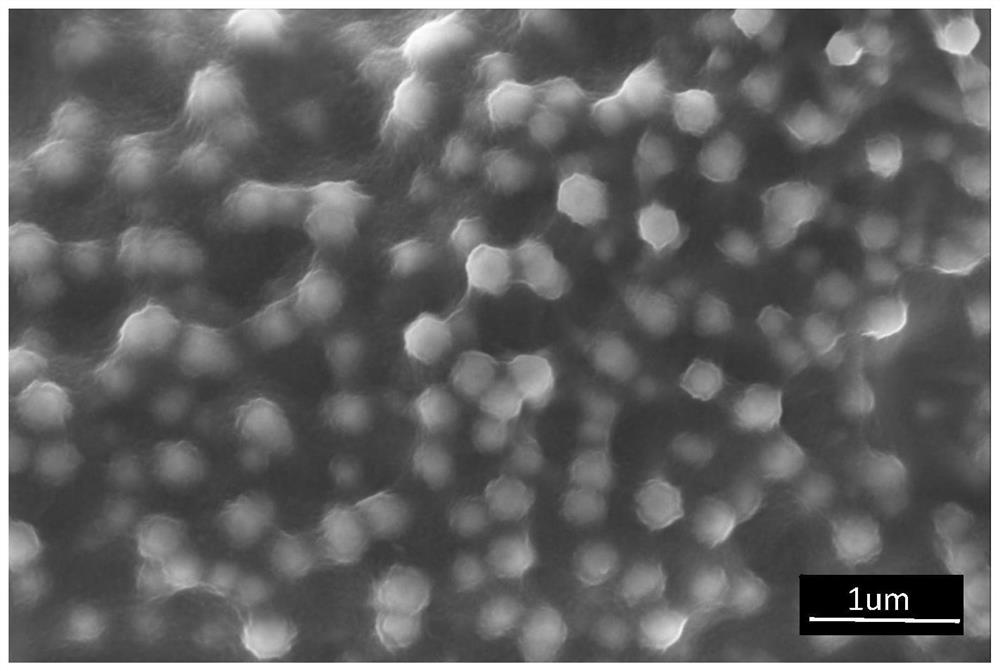

[0038] A method for preparing a nanorod arrayed surface sequentially delivering a polymer micelle coating of immunomodulatory factors, comprising the following steps:

[0039] Step 1: performing micro-arc oxidation on the pure titanium or titanium alloy substrate in an electrolyte containing phosphorus ions and calcium ions, so that a microporous titanium dioxide coating is formed on the surface of the titanium-based substrate;

[0040] Specifically: the pure titanium or titanium alloy substrate is used as the anode, and the stainless steel electrolytic cell is used as the cathode, and micro-arc oxidation is carried out at a temperature of 295-305K. After cleaning and drying with deionized water, a microporous titanium dioxide coating is formed on the surface of the titanium-based substrate. ; The parameters of micro-arc oxidation are: arc frequency 100-120Hz, positive pressure 350-450V, duty cycle 15-25%; electrolyte includes: sodium hydroxide 0.01-0.02mol / L, calcium acetate 0...

Embodiment 1

[0054] A method for preparing biomedical materials coated with polymer micelles for sequentially delivering immunomodulatory factors on the surface of nanorod arrays, comprising the following steps:

[0055] Step 1, micro-arc oxidation of titanium and its alloys:

[0056] The parameters of the micro-arc oxidation are set as follows: the arc frequency of the micro-arc oxidation is 110 Hz, the power supply is a positive voltage of 385 V, and the duty cycle is 20%. In the micro-arc oxidation process, the titanium alloy is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: sodium hydroxide (NaOH) 0.015mol / L, calcium acetate (Ca(CH 3 COO) 2 ) 0.4mol / L, β-glyceride disodium salt pentahydrate (β-GP) 0.04mol / L. During the preparation process, a cooling system is used to control the temperature of the micro-arc oxidation electrolyte at 300K. After micro-arc oxidation, the sample coated with m...

Embodiment 2

[0073] A method for preparing biomedical materials coated with polymer micelles for sequentially delivering immunomodulatory factors on the surface of nanorod arrays, comprising the following steps:

[0074] Step 1, micro-arc oxidation of titanium and its alloys:

[0075] The parameters of the micro-arc oxidation are set as follows: the arc frequency of the micro-arc oxidation is 100 Hz, the power supply is a positive voltage of 350 V, and the duty cycle is 15%. In the micro-arc oxidation process, pure titanium is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: sodium hydroxide (NaOH) 0.02mol / L, calcium acetate (Ca(CH 3 COO) 2 ) 0.3mol / L, β-glyceride disodium salt pentahydrate (β-GP) 0.05mol / L. During the preparation process, a cooling system is used to control the temperature of the micro-arc oxidation electrolyte at 295K. After micro-arc oxidation, the sample coated with micropo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com