Treatment tank for preparing cuttlefish ink

A technology of squid ink and treatment tank, which is applied in the direction of post-treatment of mixture, chemical/physical process, mixer with rotating stirring device, etc., which can solve the problems of uneven particle size of squid ink, difficulty in promoting squid ink, and not delicate taste, etc. , to achieve the effects of improving production efficiency and quality, improving stirring efficiency, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

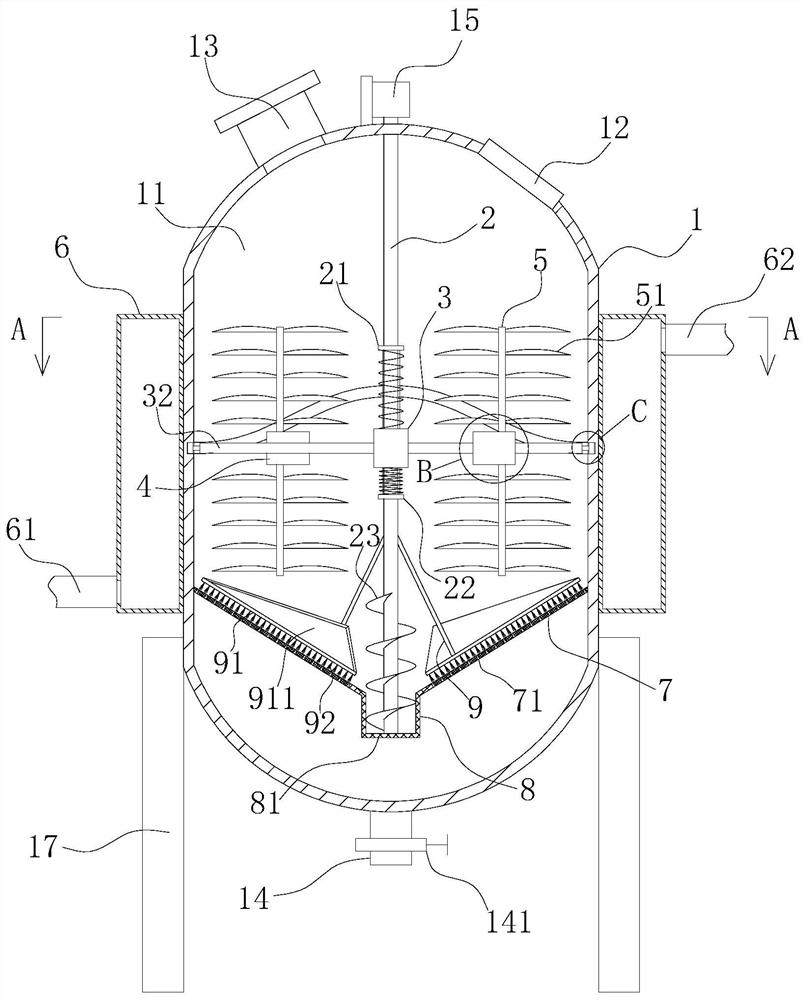

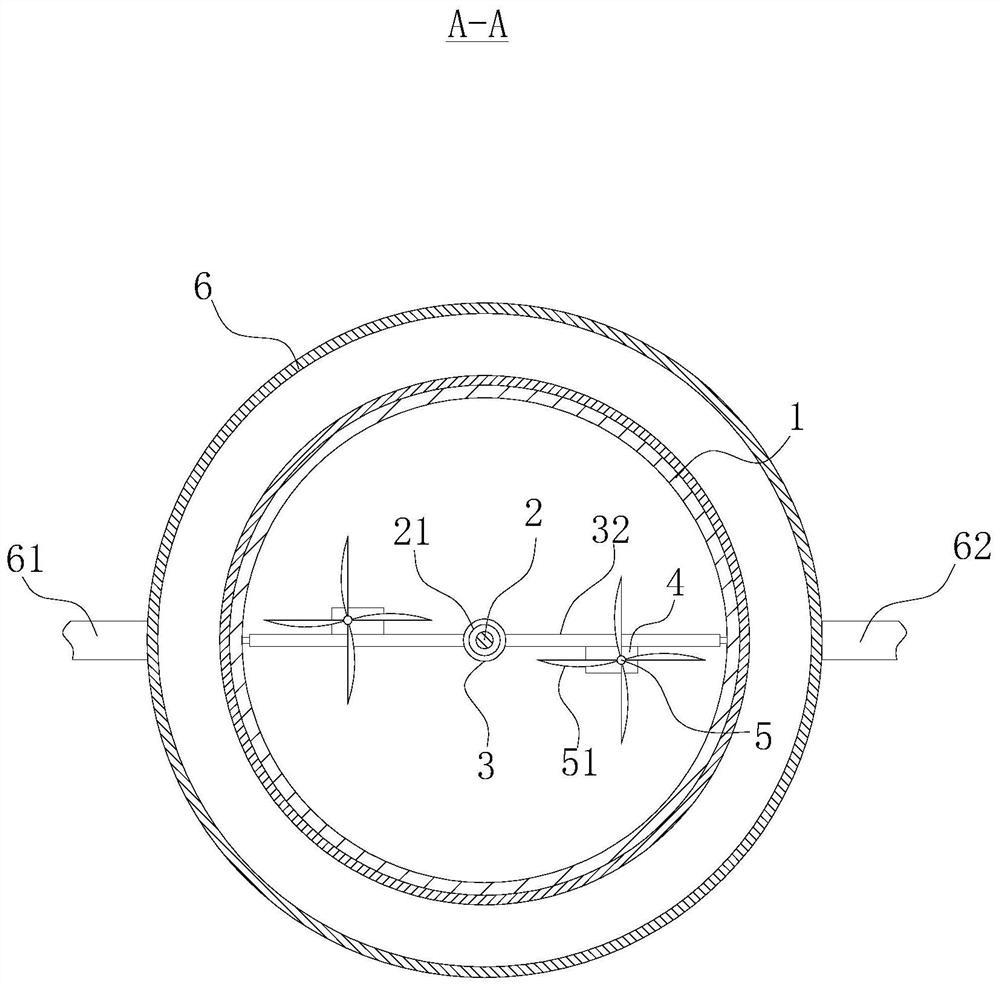

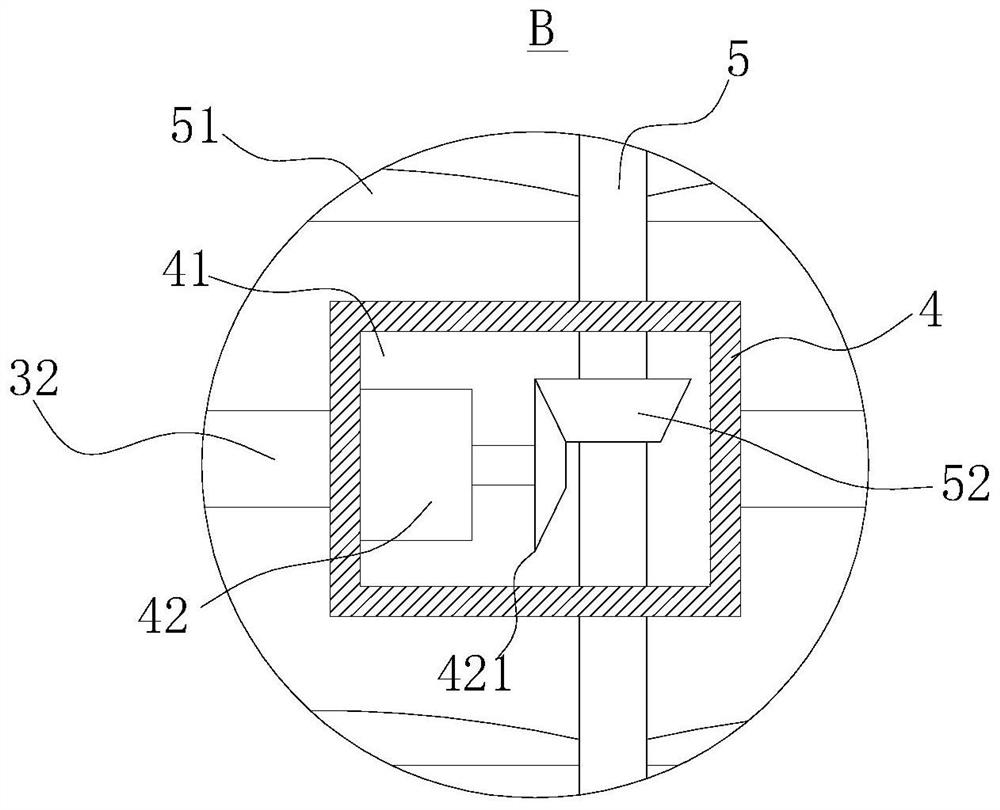

[0057] like Figures 1 to 7 As shown, a processing tank for producing squid ink includes a tank body 1, a first rotating shaft 2, a first motor 15, a sleeve 3, a guiding mechanism, two crushing mechanisms and a filtering mechanism.

[0058] The tank body 1 is provided with a reaction chamber 11, the top of the tank body 1 is provided with a feed pipe 13, the bottom of the tank body 13 is provided with a discharge pipe 14, and the discharge pipe 14 is provided with an electromagnetic Valve 141, several supporting legs 16 are provided around the bottom of the tank body 1 .

[0059] Preferably, an observation mirror 12 is provided on the top side of the tank body 1 to facilitate the operator to observe the situation in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com