High-temperature alloy bar blank upsetting forming device and method based on high-temperature-resistant medium

A high-temperature alloy and high-temperature-resistant technology, which is applied in the field of thermal processing and forging, can solve problems such as cracking, achieve good heat preservation, reduce heating times and forming processes, and avoid instability or cracking defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below.

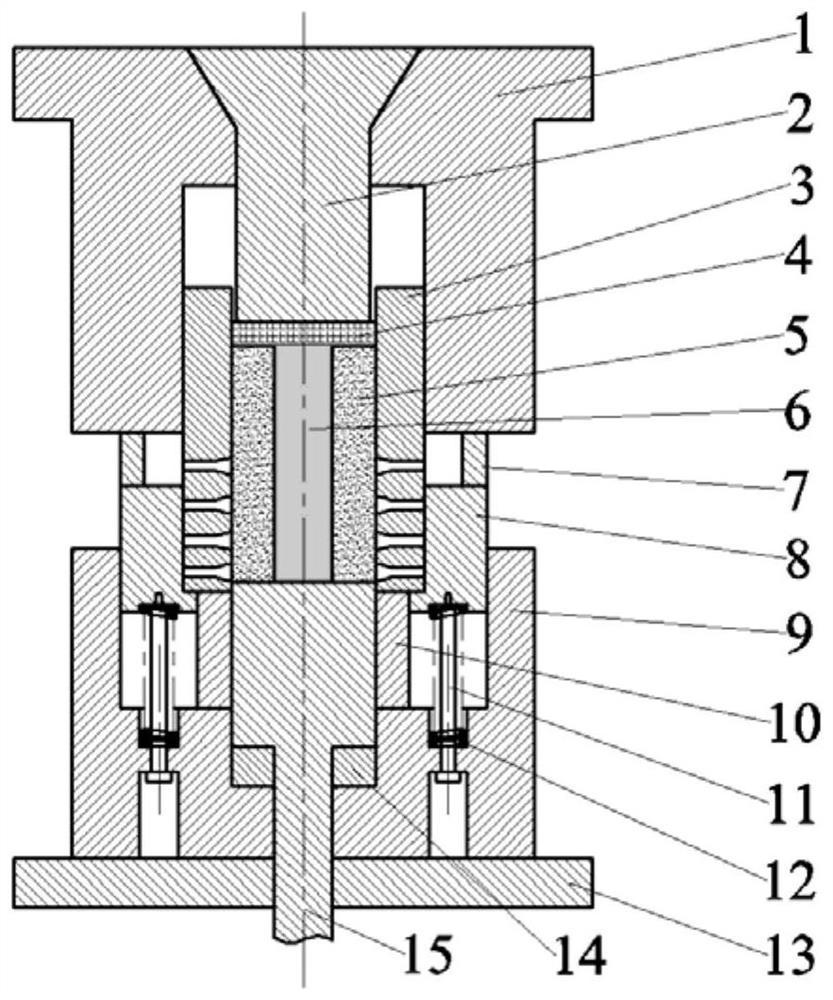

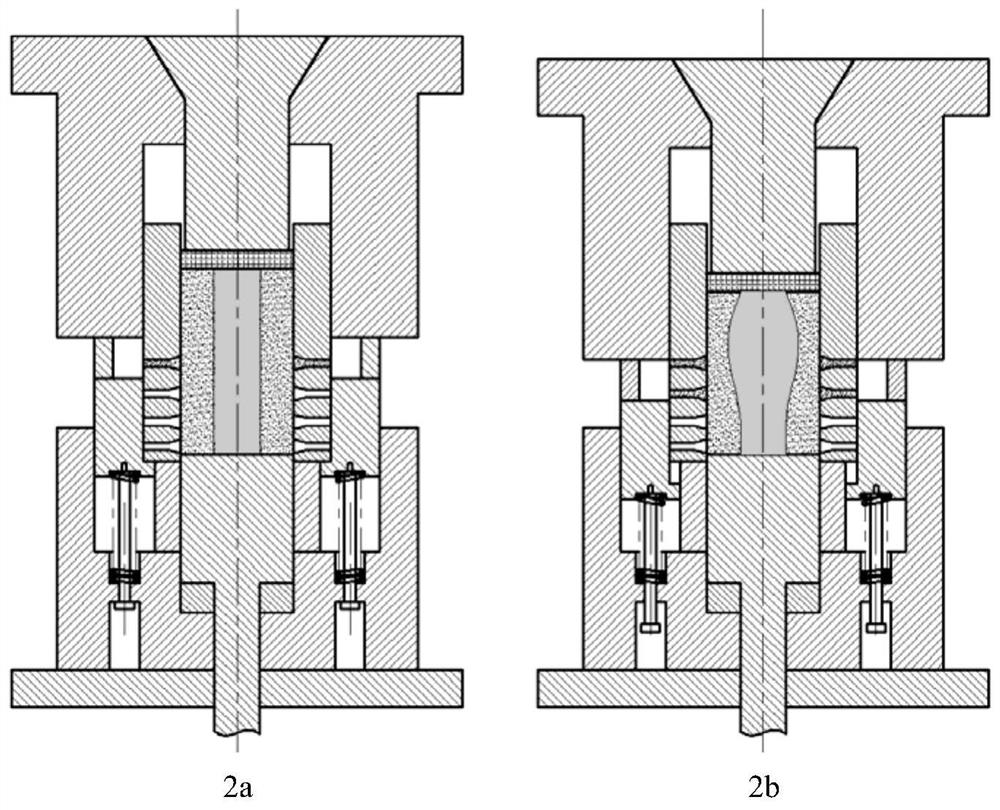

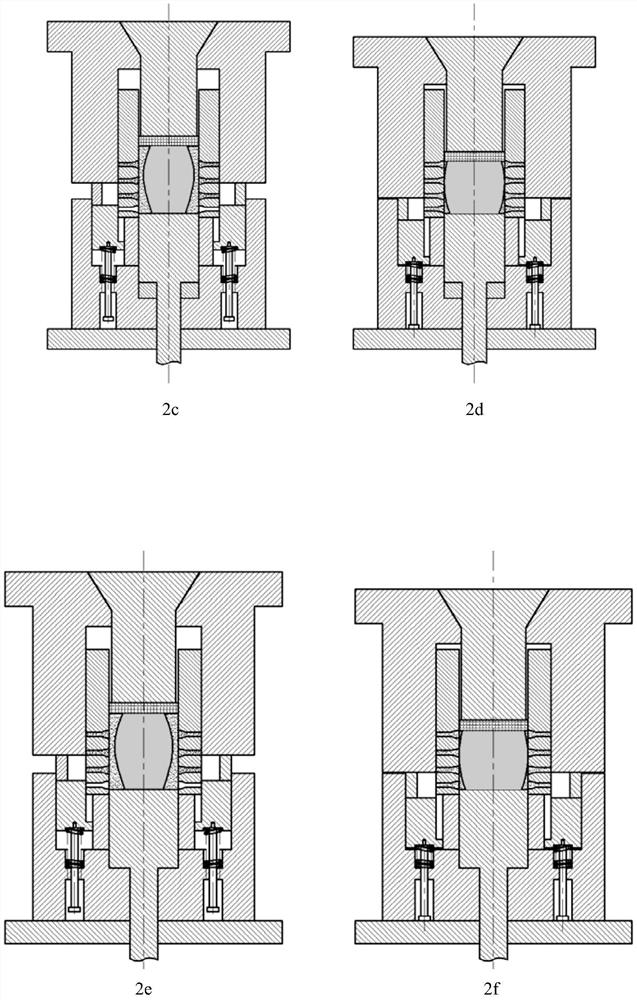

[0038] Provide an upsetting and forming device for high-temperature alloy billets based on high-temperature-resistant medium, the length-to-diameter ratio of the billet is greater than 2.5; High temperature resistant medium 5, billet 6, support ring 7, floating sleeve 8, lower die 9, lower die holder 13 and ejector pin 15;

[0039] The extrusion cylinder is installed and fixed on the lower die; the lower end of the push rod 15 is installed on the lower die 9, and the upper end of the push rod 15 closes the lower port of the extrusion cylinder 3; Pressure control holes are opened at a certain axial distance; the billet is located in the extrusion cylinder 3, and the extrusion cylinder is filled with a high temperature resistant medium 5, and the distance between the billet and the inner wall of the extrusion cylinder 3 is The high temperature resistant medium 5;

[0040] The upper die base is set on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com