Noise absorber and pneumatic tire comprising noise absorber

A technology for noise absorption and pneumatic tires, which is applied in the field of pneumatic tires and noise absorbers, can solve the problems of no targeted research and no impact on sound absorption effects, etc., achieve good sound absorption and vibration reduction effects, and improve sound absorption and noise reduction effect, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1: Sound-absorbing effect test of foam sound-absorbing bodies with different materials and structures

[0102] Sample Preparation:

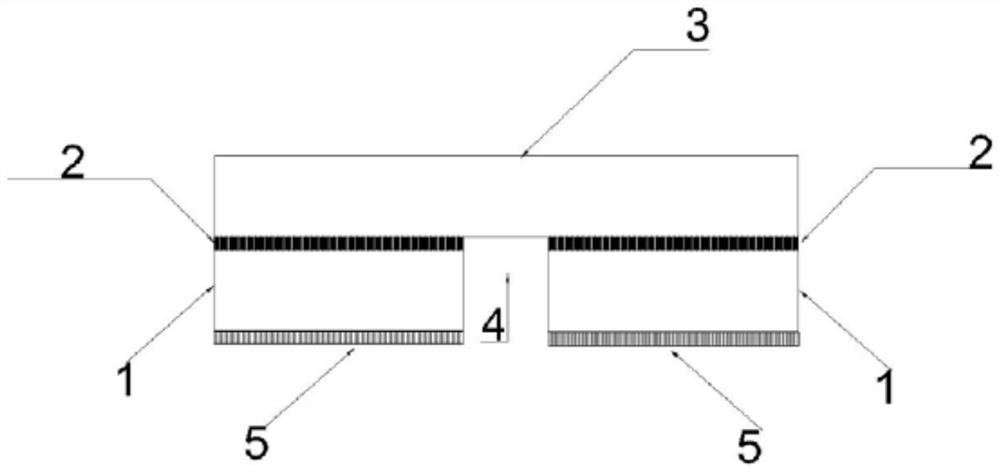

[0103] Single layer structure:

[0104] Use a ring blade with a diameter of 100mm to cut the sound-absorbing material with a thickness of 30mm to its corresponding size on a punching machine.

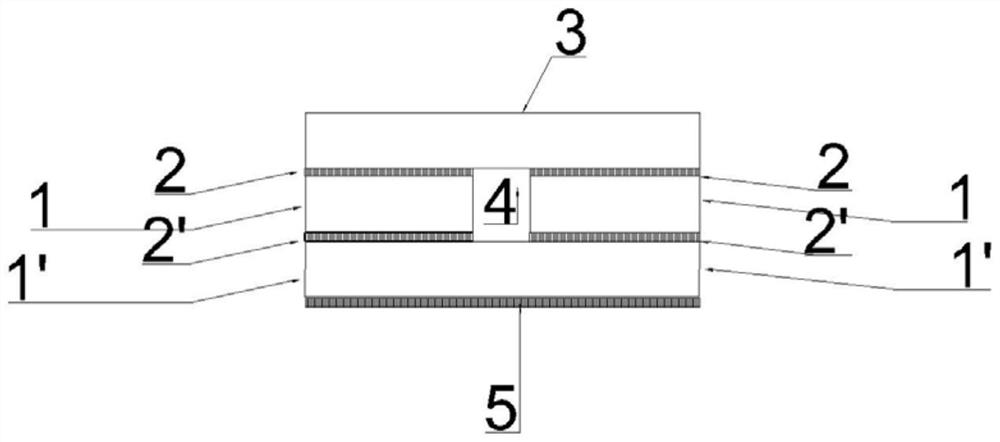

[0105] Two-tier structure:

[0106] First, attach the double-sided tape to one side of the sound-absorbing material with a thickness of 30mm to be cut, and use a circular blade with a diameter of 100mm to cut the sound-absorbing material to its corresponding size on the punching machine. Then attach another cut single-layer structure sample to the side of the sample with double-sided tape to form a two-layer structure

[0107] Three-tier structure:

[0108] First, stick double-sided tape on both sides of the sound-absorbing material with a thickness of 30mm to be cut, and use a circular blade with a diameter of 100mm to cut the sound-a...

Embodiment 2

[0126] Example 2: Adhesion test between foam and butyl rubber

[0127] T-peeled spline preparation:

[0128] Make a test sample:

[0129] Cut the butyl rubber lining layer with a thickness of 2.5mm and the sound-absorbing material with a thickness of 30mm into a spline of 140mm and 20mm in length, and glue it with double-sided tape or structural adhesive from one section to 110mm in length, and reserve 30mm as Stripped segment.

[0130] T-peel test:

[0131] The two ends of the sample bar were peeled at a speed of 300mm / min, and the peeling force was tested.

[0132] The T-type test is carried out on the foam and butyl rubber strips bonded with double-sided pressure-sensitive adhesive or structural adhesive. The T-type test data are shown in Table 4 below:

[0133] Table 4

[0134] T-type test peel force (N / 20mm) before aging After aging (100℃*7 days) Foam and Butyl Rubber 10.5 11.7

[0135] It can be seen from the above Table 4 that the nois...

Embodiment 3

[0144] Sample Preparation:

[0145] First, attach the non-woven double-sided tape to the two sides of 2 pieces of sound-absorbing material 1 with a size of 40mm*15mm*2200mm to prepare a sample of the corresponding size, and then respectively attach the two pieces of polyurethane foam to the edge of 110mm*15mm *On both ends of the same side of the sound-absorbing material 1 (polyurethane foam TWA25) with a size of 2200 mm.

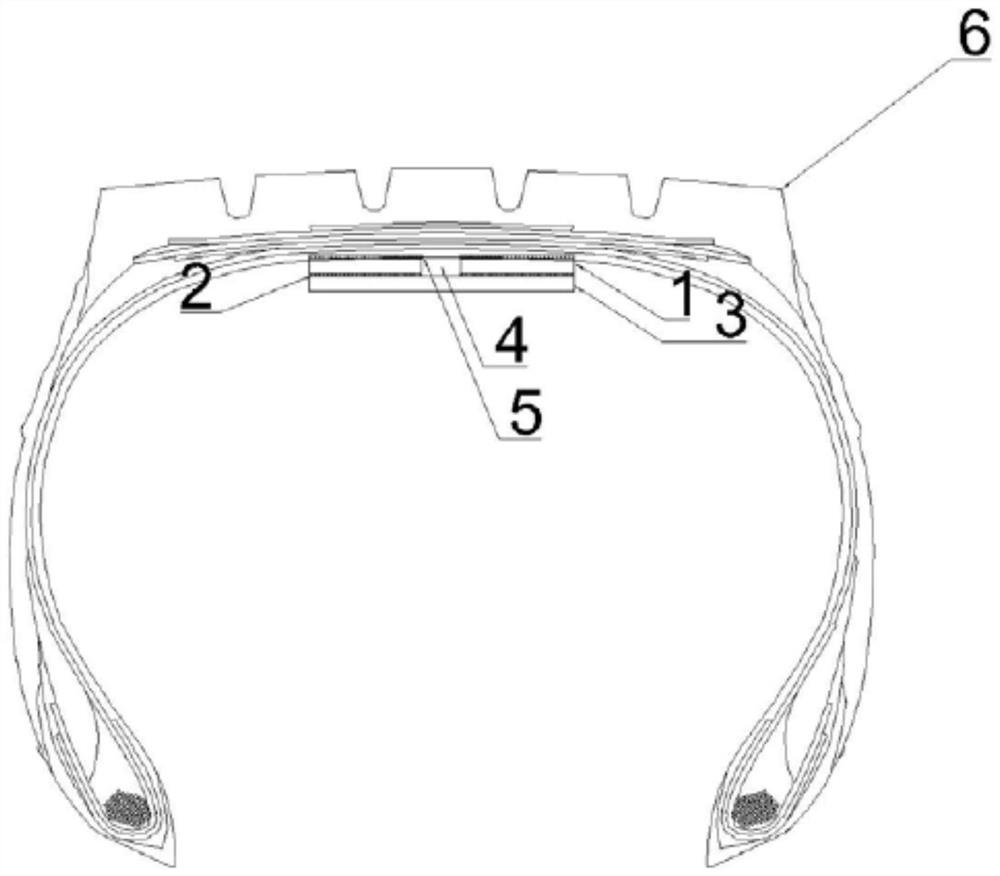

[0146] fit:

[0147] Grind or clean the inner side of the tire for a week along the circumferential direction of the tire, tear off the prepared sample with the release film side, and arrange it symmetrically on the tire cross-section with respect to the plane where the crown centerline of the tire is located.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com