Preparation and analysis method of basalt fiber transparent mixture

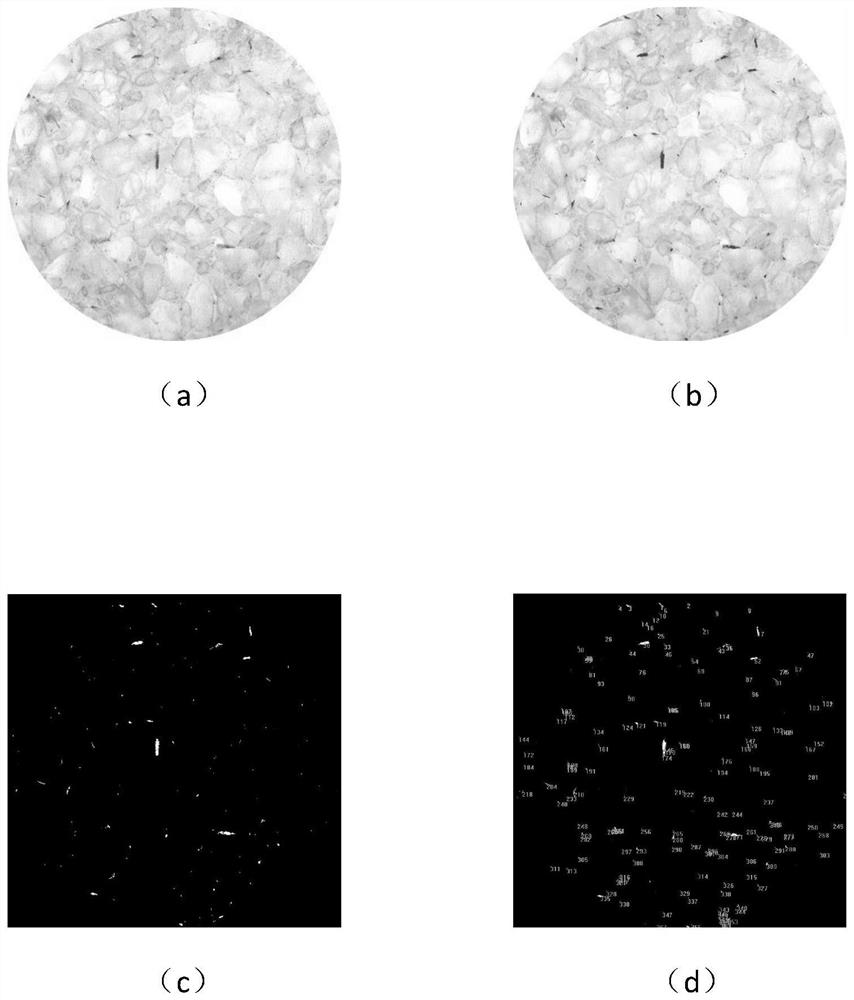

A technology of basalt fibers and mixtures, applied in image analysis, image data processing, instruments, etc., can solve the problems of difficult evaluation and analysis of basalt fiber dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

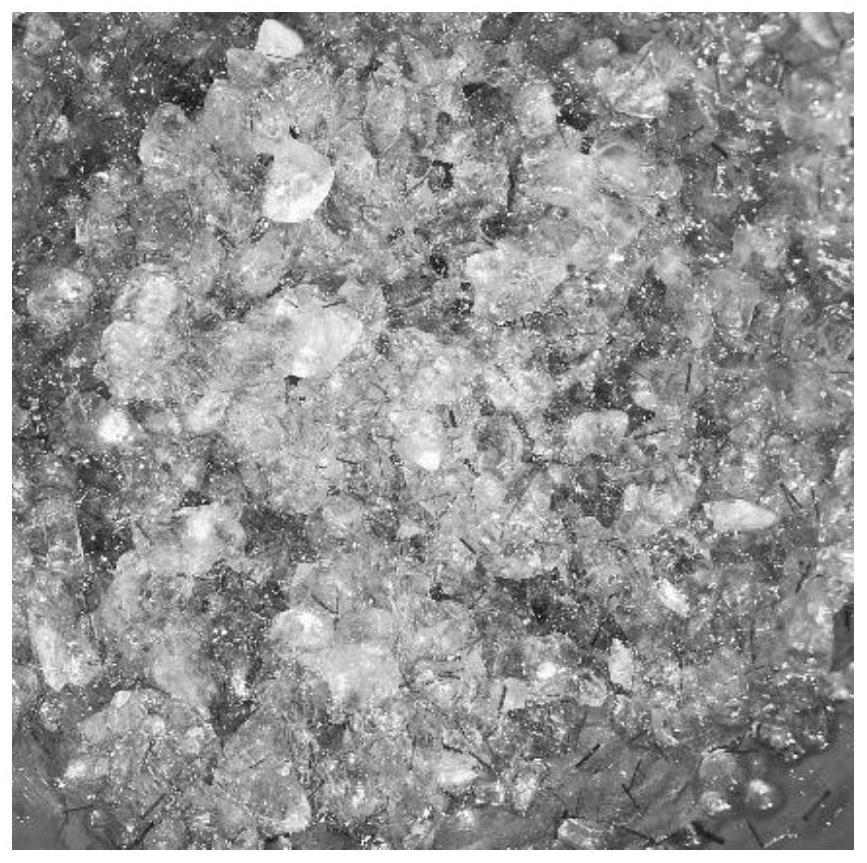

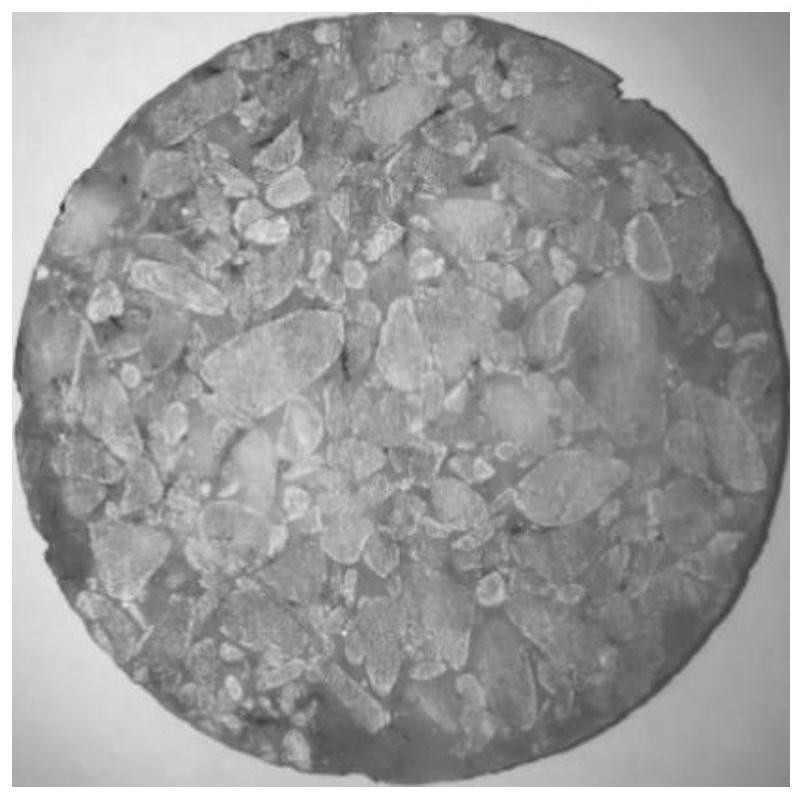

[0026] Specific embodiment 1: This embodiment discloses a method for preparing a basalt fiber transparent mixture, and the method includes the following steps:

[0027] Step 1. Select the particle size and proportion of the transparent crystal stone according to the gradation characteristics of the target asphalt mixture (for the prior art), so that its composition is close to the gradation of the asphalt mixture, and measure the skeleton gap of the transparent crystal stone rate (the test method of skeleton gap ratio is the prior art, JTG E42-2005 (T0309)), and determine the consumption of transparent binder based on the skeleton gap ratio; the transparent binder is made of epoxy resin and epoxy resin Composition of resin curing agent;

[0028] Step 2. Stir the basalt fiber with a mass fraction of 0.3% and the transparent crystal stone at room temperature for 60-90s, then add epoxy resin curing agent and stir for 60-90s, and finally add epoxy resin and continue stirring for 6...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is a further description of Embodiment 1. In step 1, the volume of the transparent cement is 70% to 80% of the porosity of the skeleton.

specific Embodiment approach 3

[0032] Specific implementation mode three: This implementation mode is a further description of specific implementation mode one. In step one, the particle size and proportion of transparent crystal stones are selected according to the gradation characteristics of the target asphalt mixture as follows:

[0033] The particle sizes of transparent crystal stones are selected as 9-12mm, 7-9mm, 5-7mm and 2-5mm respectively. According to the target SMA-13 asphalt mixture gradation, the mass proportion range values of the above four crystal stones are respectively 30%-45%, 20%-35%, 25%-40%, 5%-12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com