High-performance rubber asphalt and preparation method thereof

A rubberized asphalt and high-performance technology, applied in the field of high-performance rubberized asphalt and its preparation, can solve problems such as affecting the road use and service performance and construction quality of rubber asphalt, worsening construction workability, and increasing the viscosity of modified asphalt, etc. To achieve the effect of improving suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

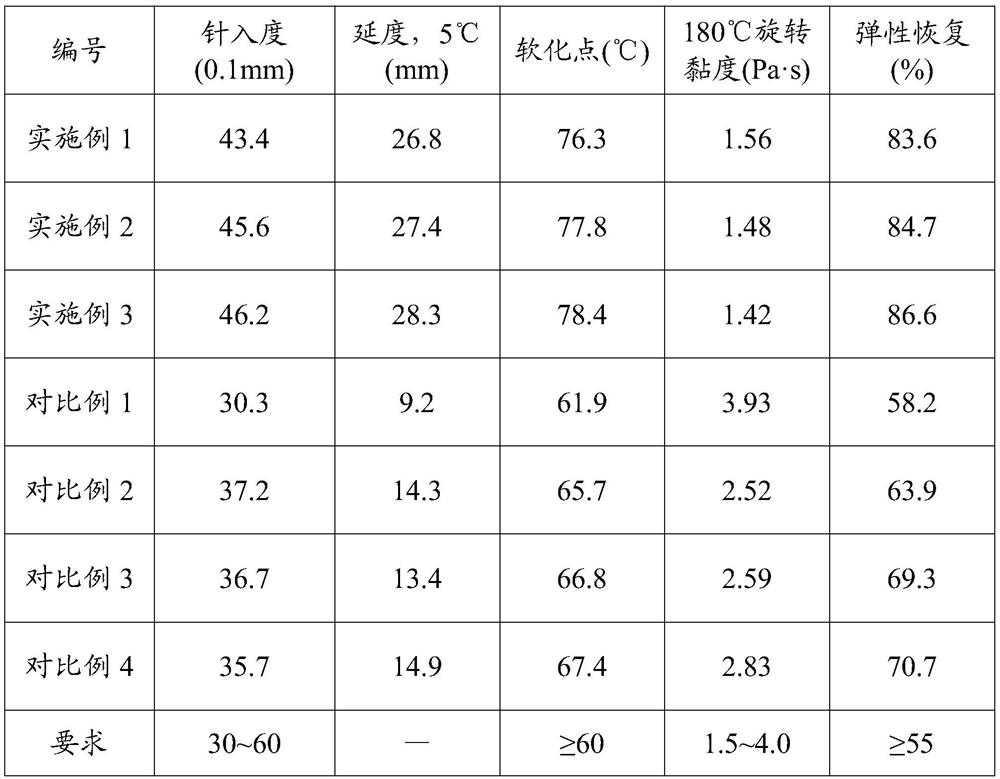

Examples

Embodiment 1

[0026] A high-performance rubber asphalt, comprising the following components by weight: 80 parts of No. 70 A-grade asphalt with a penetration of 6mm and a softening point greater than 45°C, 18 parts of 30-mesh tire rubber powder, 1 part of Eucommia gum, butadiene 0.5 parts, sulfur 0.4 parts, dibenzoyl peroxide 0.05 parts, tris (2,4-di-tert-butylphenyl) phosphite 0.05 parts.

[0027] The preparation method of above-mentioned high-performance rubber asphalt may further comprise the steps:

[0028] (1) Weigh No. 70 A-grade asphalt, 30 mesh tire rubber powder, Eucommia gum, butadiene, sulfur, dibenzoyl peroxide, tris(2,4-di-tert-butylphenyl) in parts by weight Phosphite spare;

[0029] (2) Place the 30-mesh tire rubber powder, Eucommia gum, and dibenzoyl peroxide weighed in step (1) in a banbury mixer for banburying, with a banburying speed of 50r / min, a temperature of 130°C, and a time of 15min;

[0030] (3) Add sulfur, butadiene and tris(2,4-di-tert-butylphenyl)phosphite to t...

Embodiment 2

[0033] A high-performance rubber asphalt, comprising the following components by weight: 80 parts of No. 70 A-grade asphalt with a penetration of 7mm and a softening point greater than 45°C, 19 parts of 35-mesh tire rubber powder, 1.3 parts of Eucommia gum, butadiene 0.7 parts, 0.6 parts of sulfur, 0.07 parts of dibenzoyl peroxide, and 0.07 parts of tris(2,4-di-tert-butylphenyl)phosphite.

[0034] The preparation method of above-mentioned high-performance rubber asphalt may further comprise the steps:

[0035] (1) Weigh No. 70 grade A bitumen, 35 mesh tire rubber powder, Eucommia gum, butadiene, sulfur, dibenzoyl peroxide, tris(2,4-di-tert-butylphenyl) by parts by weight Phosphite spare;

[0036] (2) Place the tire rubber powder, eucommia gum, and dibenzoyl peroxide weighed in step (1) in a banbury mixer for banburying, with a banburying speed of 50r / min, a temperature of 140°C, and a time of 13min;

[0037] (3) Add sulfur, butadiene and tris(2,4-di-tert-butylphenyl)phosphit...

Embodiment 3

[0040] A high-performance rubber asphalt, comprising the following components by weight: 80 parts of No. 70 A-grade asphalt with a penetration of 8mm and a softening point greater than 45°C, 20 parts of 40-mesh tire rubber powder, 1.5 parts of Eucommia gum, butadiene 1.0 parts, 0.8 parts of sulfur, 0.1 parts of dibenzoyl peroxide, and 0.1 parts of tris(2,4-di-tert-butylphenyl)phosphite.

[0041] The preparation method of above-mentioned high-performance rubber asphalt may further comprise the steps:

[0042] (1) Weigh No. 70 A grade asphalt, 40 mesh tire rubber powder, Eucommia gum, butadiene, sulfur, dibenzoyl peroxide, tris(2,4-di-tert-butylphenyl) by weight parts Phosphite spare;

[0043] (2) Place the tire rubber powder, Eucommia gum, and dibenzoyl peroxide weighed in step (1) in a banbury mixer for banburying, with a banburying speed of 50r / min, a temperature of 150°C, and a time of 10min;

[0044](3) Add sulfur, butadiene and tris(2,4-di-tert-butylphenyl)phosphite to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com