Multifunctional automatic cleaning ship

A cleaning boat, multi-functional technology, applied in the cleaning of open water, motor vehicles, electric vehicles, etc., can solve the problems of self-weight falling, difficult conveyor belt transmission, low efficiency, etc., to avoid garbage leakage and reduce interaction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

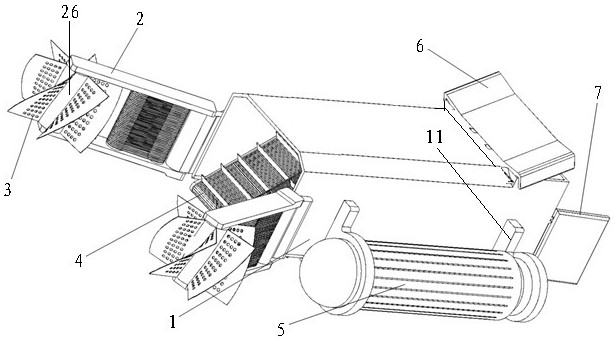

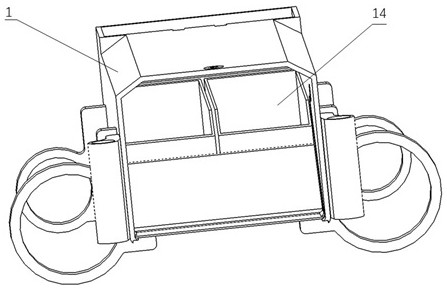

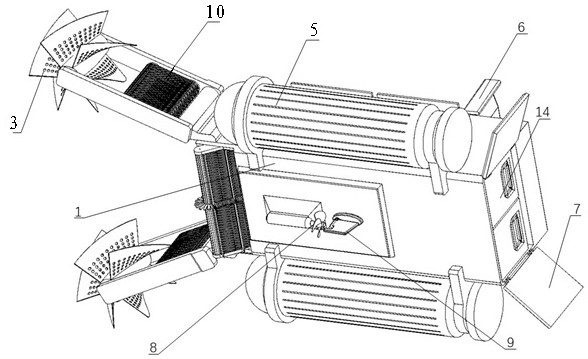

[0052] As shown in the figure: a multi-functional automatic cleaning ship, including the main body, swing arm, blade, column, conveyor belt, top cover, rear hatch, permeable board, partition, cutting board, garbage bin, gripper, monitoring equipment, Main arm, left arm, right arm, supporting plate, fixed ring, buoy, propeller, rudder blade, solar panel, camera, searchlight; wherein the swing arm includes an upper plate and a lower plate, and the cutting plate is composed of multiple sub-plates , the blade includes a blank portion and a perforated portion;

[0053] Wherein, the bottom of the main body is provided with the propeller and the rudder blade, the top of the main body is provided with the solar panel, the top cover is located behind the solar panel, and the upper surface of the top cover includes The left slope, the front, and the right slope, when the top cover is lifted, the left slope, the front, and the right slope refract light onto the solar panel; the camera an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com