Method for carrying out bearing capacity and pull-out test on tire reinforced soil foundation by using same device

A technology for ground bearing capacity and pull-out test, applied in the field of civil engineering and geological engineering test, can solve the problems of large instrument and complicated test steps, and achieve the effect of simple structure, high test accuracy and reduction of waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

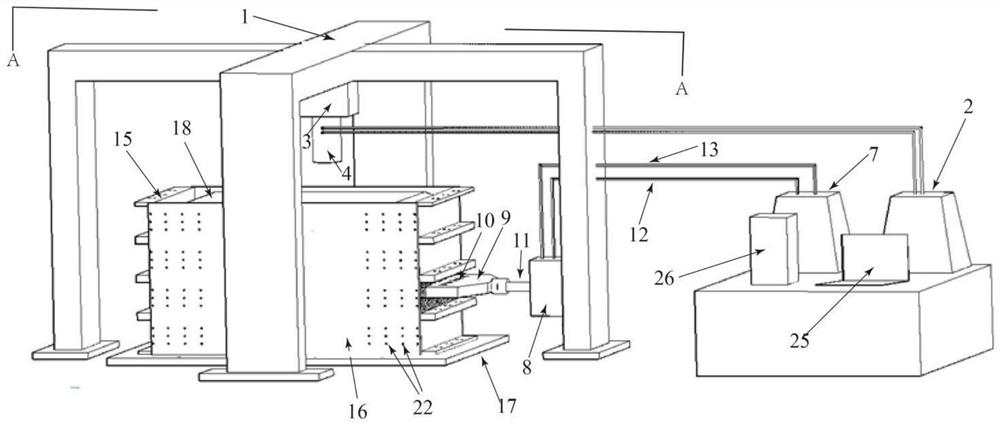

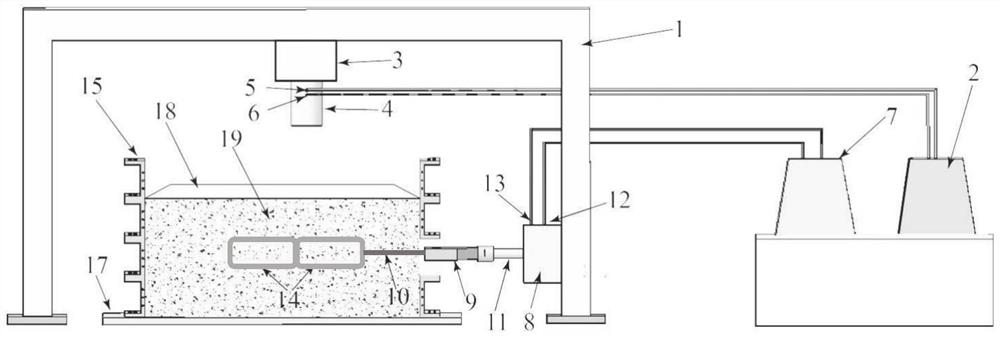

Embodiment 1

[0084] Scrap tire pulling test procedure of the present invention is as follows: Figure 9 shown.

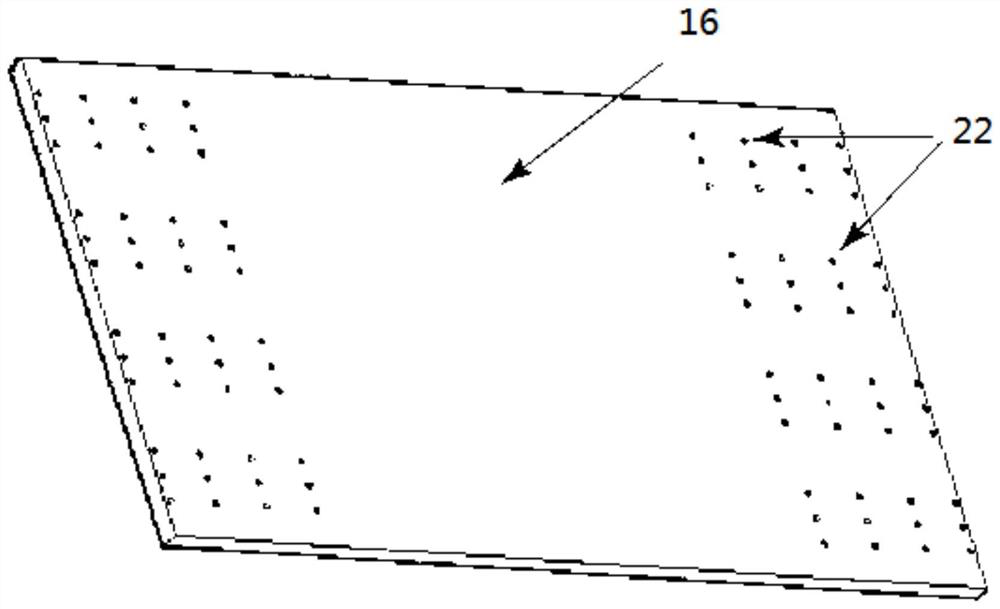

[0085] Determine the test conditions, assemble the test box and prepare the packing (involving S1-S2). The burial depth is 1.5m. For a single tire, the tire shape parameters are: tread height 40mm, tire cross-section shape is circular, tire outer diameter 200mm, tire skin thickness 15mm. The internal dimensions of the test box are 600mm×500mm×220mm in length×width×height. Adjust the effective length x width x height of the telescopic loading plate to be 550mm x 400mm x 10mm. The number of channel steels is 8 (4 on each side). The type of filler is sandy soil with a moisture content of 0% and a density of 1.9g / cm 3 , The degree of compaction of the filler in the box is 65%. Place the bottom plate on the level ground, then fix a layer of channel steel on the bottom plate through the screw holes on the channel steel wing plate, then select a rectangular steel plate, select the...

Embodiment 2

[0092] The bearing capacity test steps of waste tire reinforced soil foundation of the present invention are as follows: Figure 10 shown.

[0093] Determine the test conditions, assemble the test box and prepare the filler (involving A1). Two tires are horizontally arranged in a rectangular shape. The tire shape parameters are: tread height 30mm, tire cross-section shape is circular, tire outer diameter 200mm, tire skin thickness 10mm. The internal dimensions of the test box are length x width x height 1500mm x 500mm x 400mm. The adjusted size of the telescopic loading plate is: length×width×height is 1300mm×400mm×20mm. The number of channel steels is 12 (6 on each side). The type of filler is construction waste with a moisture content of 10% and a density of 1.84g / cm 3 , The degree of compaction of the filler in the box is 80%.

[0094] Sample filling (involving A2). The construction waste is loaded in the form of layered filling. The thickness of each layer is 50mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com