Micro optical fiber magnetic field sensor based on magnetostrictive material and preparation method

A technology of magnetostrictive materials and magnetic field sensors, which is applied to the use of magneto-optical equipment for magnetic field measurement, the size/direction of the magnetic field, and the direction of instruments. The effect of improving the response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

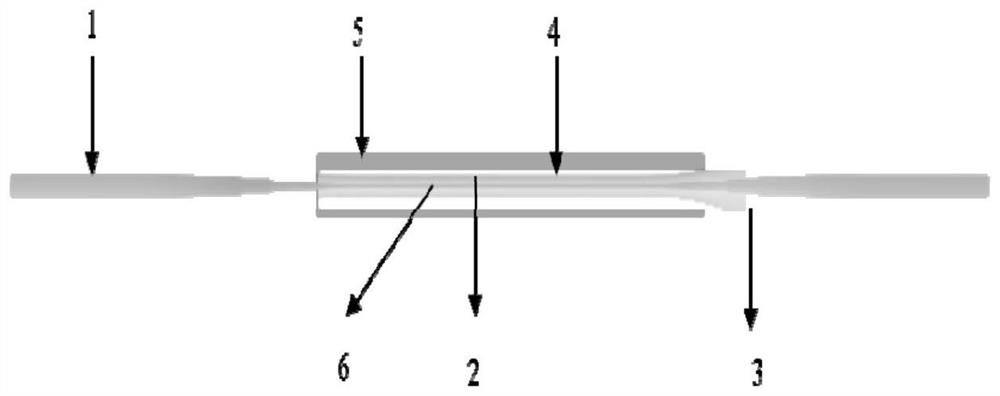

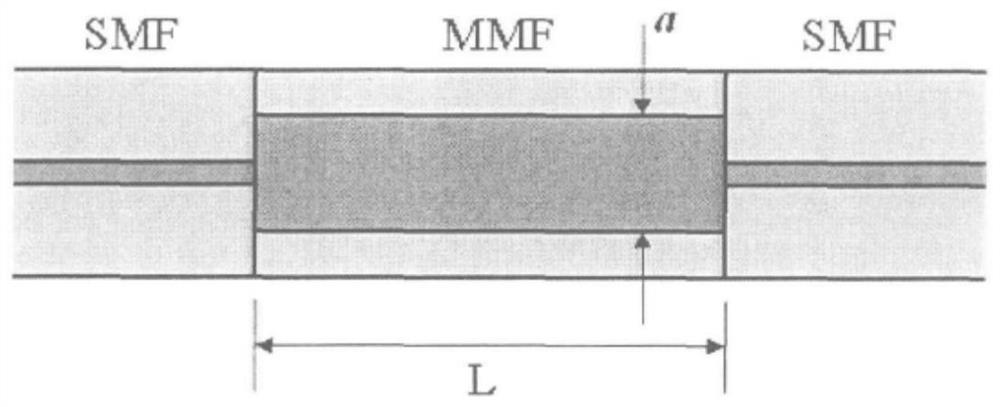

[0036] Depend on figure 1 It can be seen that the micro-fiber magnetic field sensor based on magnetostrictive material according to the present invention has a structure including a single-mode fiber pigtail 1, an optical fiber waist region 2, an optical fiber transition region 3, a PDMS film 4, a Terfenol-D film 5, Tapered multimode fiber 6; multimode fiber 6 is tapered to about 9 microns in diameter at the waist region; single-mode fiber pigtail 1 is spliced at both ends of the multimode fiber; PDMS film is cured on the surface of the microfiber by sweep coating as a stress conduction layer ; Terfenol-D film overlaid on PDMS film.

[0037] Among them, the single-mode fiber pigtail 1 is an optical waveguide, preferably a single-mode fiber; the PDMS film 4 is prepared by the PDMS solution sweep coating method, with a preferred thickness of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com