Full-color Micro-LED display panel and manufacturing method thereof

A display panel, full-color technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that affect the display contrast, color purity and saturation, crosstalk, and affect the image quality of full-color Micro-LED display, etc. Achieve the effects of improving processing efficiency, meeting high-precision requirements, and solving luminous crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

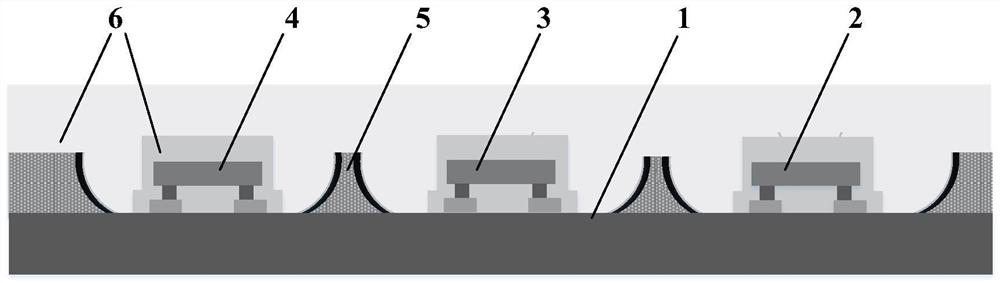

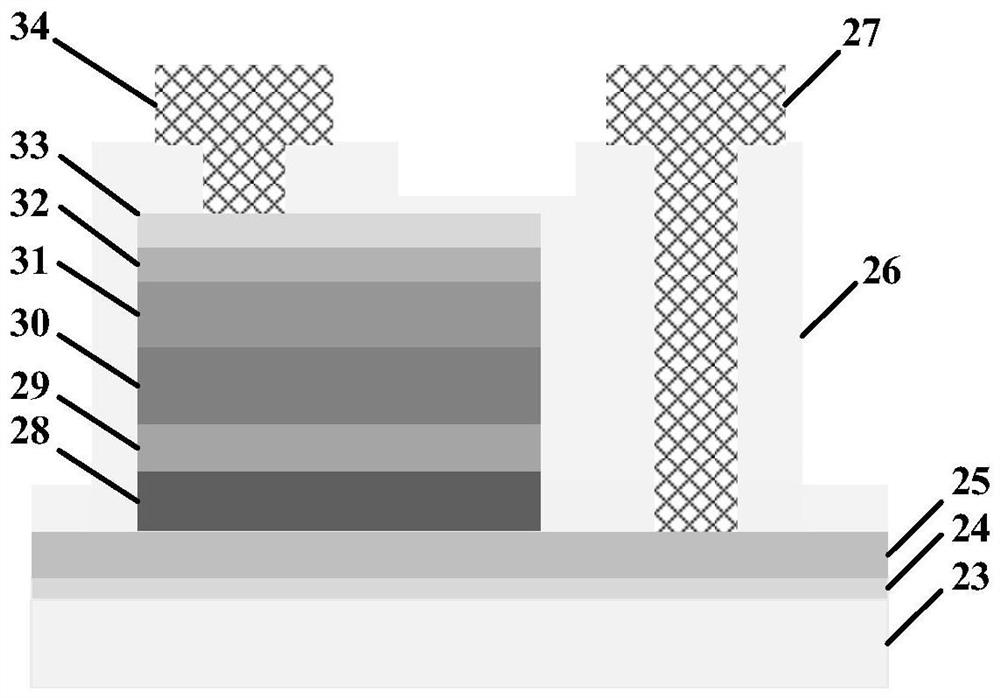

[0043] Embodiment 1 provides a full-color Micro-LED display panel, including: a driver panel, a three-primary-color Micro-LED chip array, a curved reflector array, and packaging glue; the three-primary-color Micro-LED chip array, the curved surface reflection The mirror arrays are all placed on the drive panel; the three primary color Micro-LED chip arrays include several flip-chip red Micro-LED chips, flip-chip green Micro-LED chips and flip-chip blue Micro-LED chips; The curved reflector array includes several curved reflectors, and several curved reflectors form a cavity array, and a reflective layer is deposited on the inner wall of the cavity array; Red Micro-LED chip, the flip-chip green Micro-LED chip and the flip-chip blue Micro-LED chip; the encapsulation glue is filled in the cavity array, and the encapsulation glue covers the Micro-LED chip and the curved mirror.

[0044] The DBR reflective layer in the flip-chip red Micro-LED chip, the flip-chip green Micro-LED ch...

Embodiment 2

[0064] Embodiment 2 provides a method for preparing the Micro-LED display chip as described in Embodiment 1, comprising the following steps:

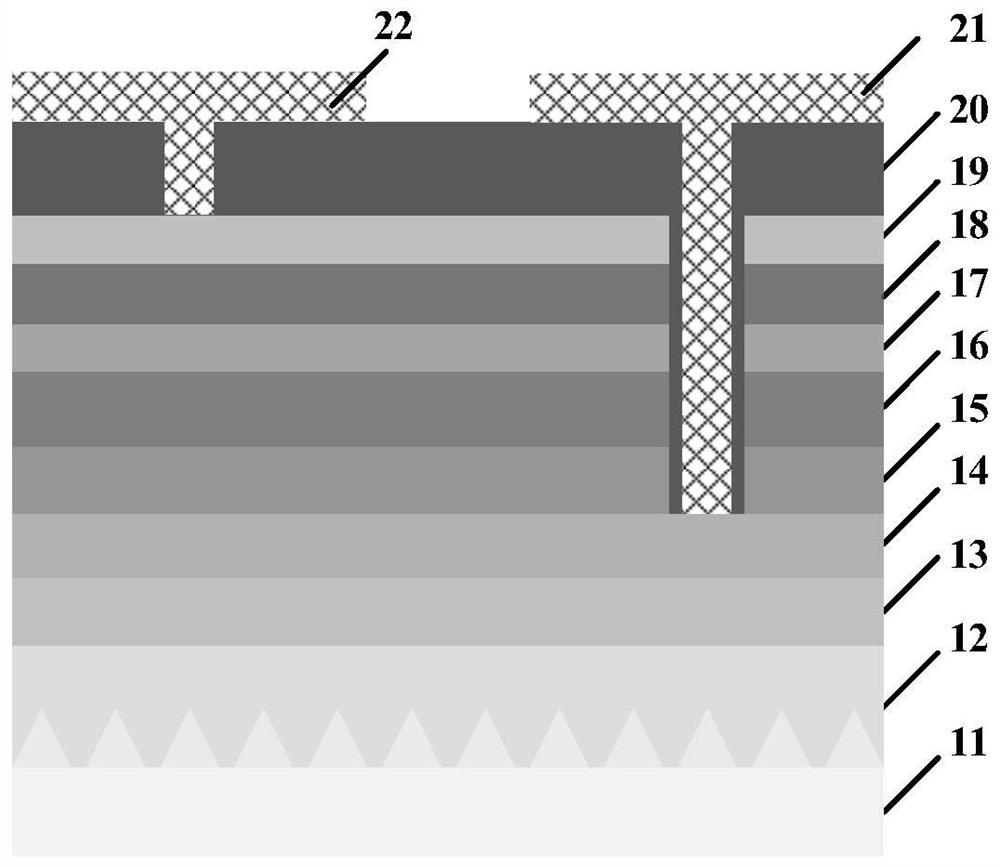

[0065] Step 1. Obtain flip-chip red Micro-LED chips, flip-chip green Micro-LED chips, and flip-chip blue Micro-LED chips with complete structures.

[0066] Obtain flip-chip red, green, and blue Micro-LED chips with a complete structure, specifically from epitaxial growth to p- / n-electrode deposition and other complete Micro-LED chip structures. The length of each chip is 30-60 microns, and the width It is 30-60 microns, and the thickness is 8-10 microns.

[0067] Step 2. Bond the three primary color flip-chip Micro-LED chips (the flip-chip red Micro-LED chip, the flip-chip green Micro-LED chip and the flip-chip blue Micro-LED chip) to the driver panel in sequence Above, a three-color Micro-LED chip array is formed; the lateral distance between two adjacent Micro-LED chips is greater than the chip length, and the vertical distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com