Antistatic silica gel compound as well as preparation method and application thereof

An anti-static and compound technology, applied in the field of anti-static silica gel compounds and their preparation, can solve the problems of unsustainable anti-static effect, unstable and incomplete curing of silica gel, etc. The effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

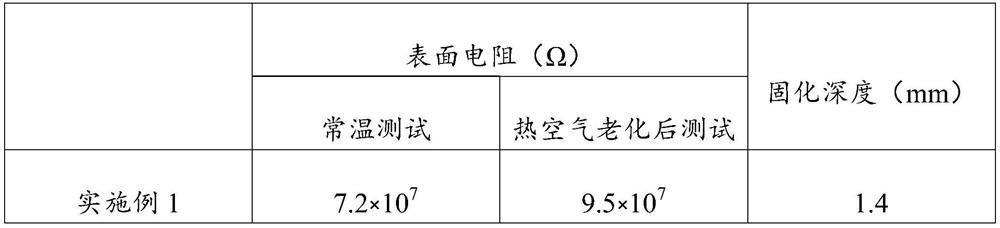

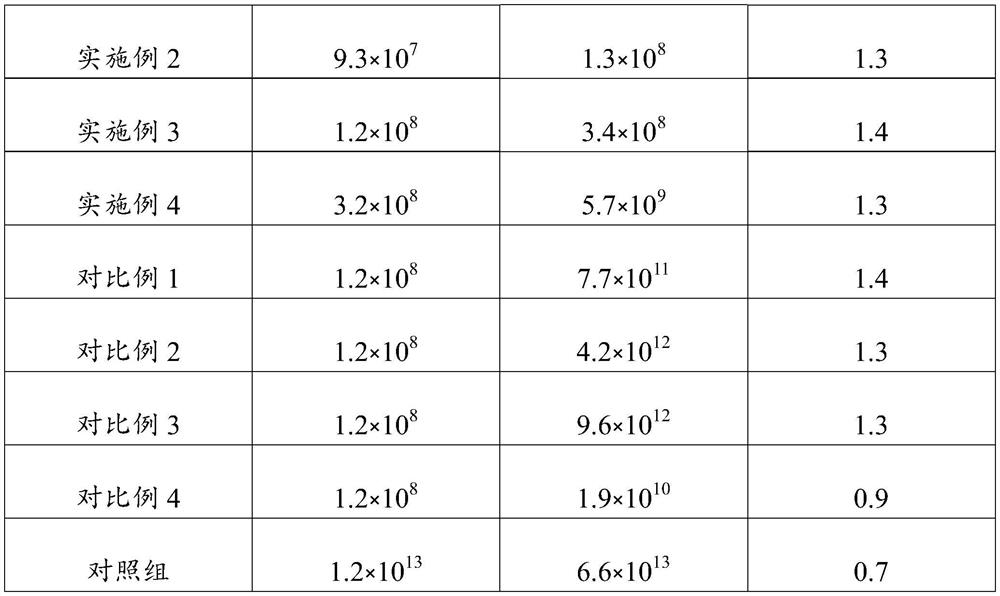

Examples

Embodiment 1

[0030] The antistatic silicone compound described in this embodiment includes the following components in parts by weight: 1 part of allyl polyether, 0.1 part of vinyltrimethoxysilane, and 0.3 part of hydrogen-containing silicone oil.

[0031] The preparation method of described antistatic silica gel compound, comprises the steps:

[0032] (1) Mix allyl polyether and hydrogen-containing silicone oil and dehydrate at 70-90°C and -0.08MPa pressure for 20-40min, and release nitrogen to normal pressure;

[0033] (2) After step (1) is depressurized, continue to add vinyltrimethoxysilane, then after the temperature of the reaction solution rises to 110-130°C, add Karlster platinum catalyst to react for 30-60min; Karlster platinum catalyst The mass is 0.3% of the total mass of allyl polyether, vinyltrimethoxysilane and hydrogen-containing silicone oil; and the platinum content in Karlster platinum catalyst is 5000ppm;

[0034] (3) After the reaction is completed, the temperature is ...

Embodiment 2

[0039] The antistatic silicone compound described in this embodiment includes the following components in parts by weight: 1 part of allyl polyether, 0.05 part of vinyltrimethoxysilane, and 0.6 part of hydrogen-containing silicone oil.

[0040] The preparation method of described antistatic silica gel compound, comprises the steps:

[0041] (1) Mix allyl polyether and hydrogen-containing silicone oil and dehydrate at 70-90°C and -0.08MPa pressure for 20-40min, and release nitrogen to normal pressure;

[0042] (2) After step (1) is depressurized, continue to add vinyltrimethoxysilane, then after the temperature of the reaction solution rises to 110-130°C, add Karlster platinum catalyst to react for 30-60min; Karlster platinum catalyst The mass is 0.3% of the total mass of allyl polyether, vinyltrimethoxysilane and hydrogen-containing silicone oil; and the platinum content in Karlster platinum catalyst is 5000ppm;

[0043] (3) After the reaction is completed, the temperature is...

Embodiment 3

[0048] The antistatic silicone compound described in this embodiment includes the following components in parts by weight: 0.5 part of allyl polyether, 0.15 part of vinyltrimethoxysilane, and 0.5 part of hydrogen-containing silicone oil.

[0049] The preparation method of described antistatic silica gel compound, comprises the steps:

[0050] (1) Mix allyl polyether and hydrogen-containing silicone oil and dehydrate at 70-90°C and -0.08MPa pressure for 20-40min, and release nitrogen to normal pressure;

[0051] (2) After step (1) is depressurized, continue to add vinyltrimethoxysilane, then after the temperature of the reaction solution rises to 110-130°C, add Karlster platinum catalyst to react for 30-60min; Karlster platinum catalyst The mass is 0.3% of the total mass of allyl polyether, vinyltrimethoxysilane and hydrogen-containing silicone oil; and the platinum content in Karlster platinum catalyst is 5000ppm;

[0052] (3) After the reaction is completed, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com