Nano silicon dioxide modified PVB material and preparation method thereof

A nano-silica and modification technology, which is applied in the composite field of polymers and nanoparticles, can solve problems such as the inability to guarantee the strength of glass interlayers, damage to personnel and objects, etc., and achieve the effect of tight combination, increased strength, and close connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

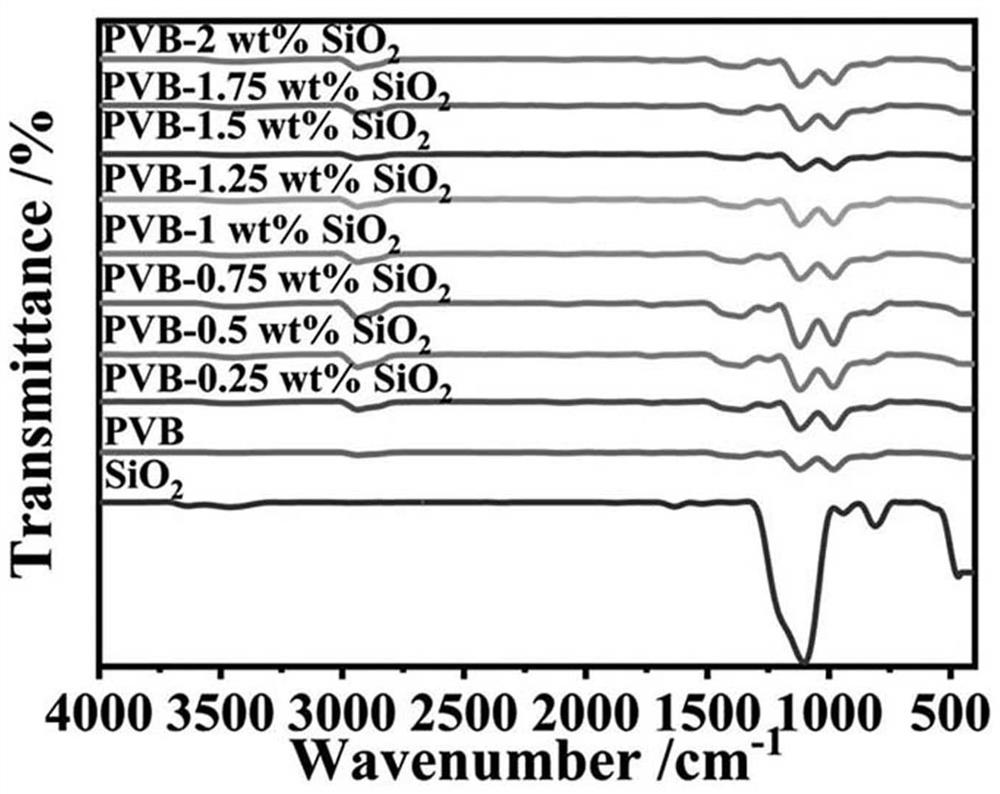

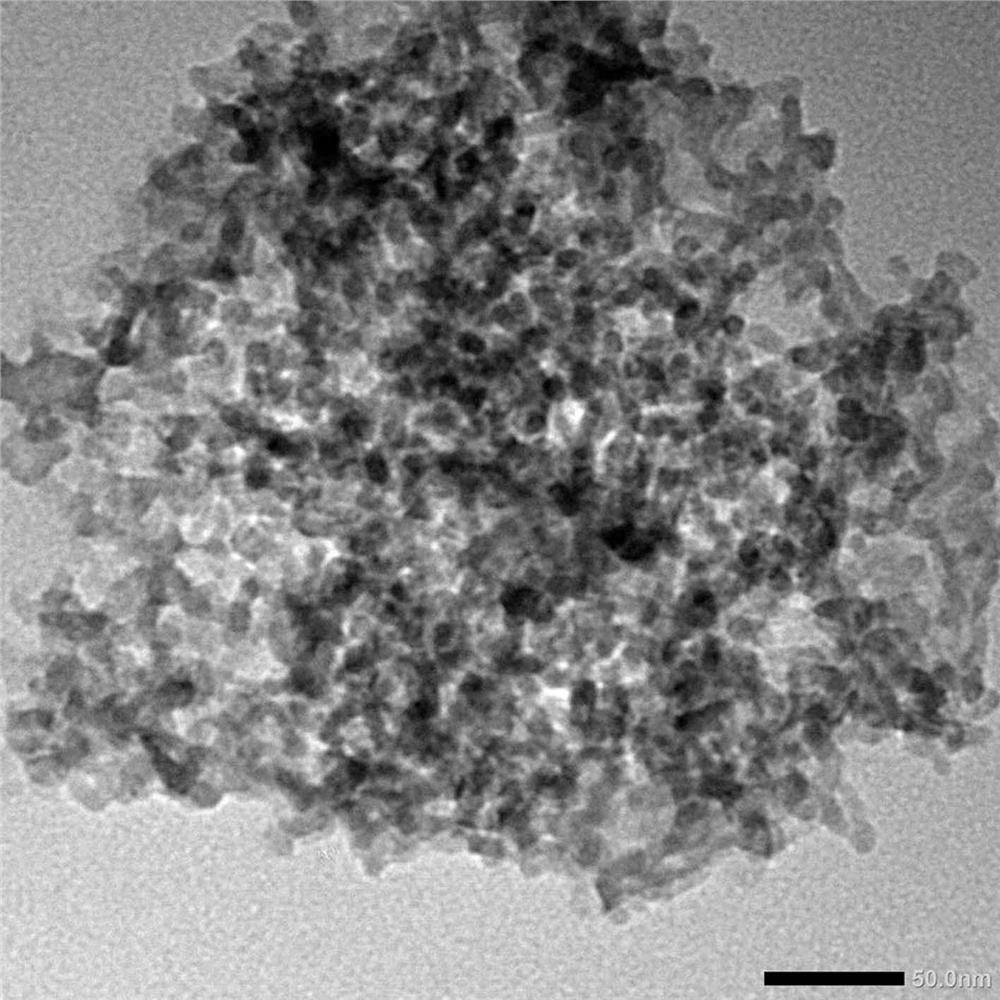

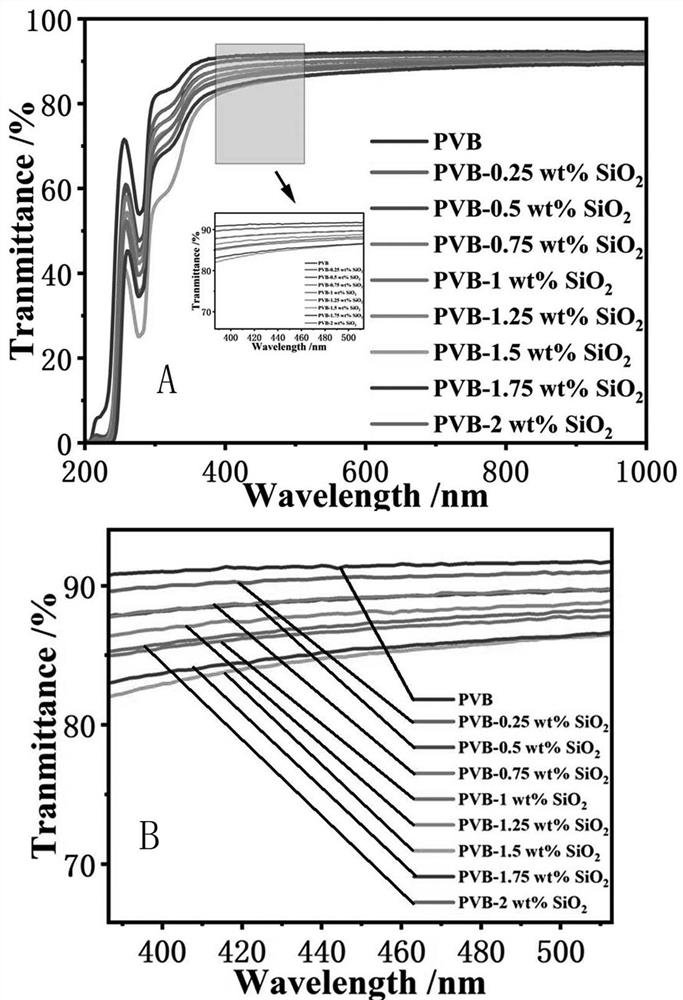

Method used

Image

Examples

Embodiment 1

[0030] A nano-silica modified PVB material is prepared by introducing nano-silica into the PVB material in situ, and its preparation method comprises the following steps:

[0031] 1) Weigh 25g of polyvinyl alcohol and 200g of deionized water, add 0.1g of antioxidant under the action of mechanical stirring, raise the temperature to 95°C and keep it for 1 hour to ensure that the PVA is completely dissolved; in this example, the antioxidant is β- (3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate;

[0032] 2) Cool down to 25°C, add 0.1g of emulsifier, add 0.1g of nano-silicon dioxide, homogeneously emulsify for 1 hour, add 15g of n-butyraldehyde, continue to cool down to 10°C, add 20g of hydrochloric acid (the concentration of hydrochloric acid is 7wt%), keep Keep the temperature unchanged for 1h; in the present embodiment, the emulsifier is sodium diisooctyl sulfonate;

[0033] 3) Raise the temperature to 70°C at a constant speed, keep it warm for 2 hours, add sodium hydr...

Embodiment 2

[0035] A nano-silica modified PVB material is prepared by introducing nano-silica into the PVB material in situ, and its preparation method comprises the following steps:

[0036] 1) Weigh 20g of polyvinyl alcohol and 250g of deionized water, add 0.05g of antioxidant under the action of mechanical stirring, heat up to 90°C for 2 hours to ensure that PVA is completely dissolved; in this example, the antioxidant is β- (3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate;

[0037] 2) Cool down to 20°C, add 0.05g of emulsifier, add 1g of nano-silicon dioxide, homogeneously emulsify for 1.5h, add 10g of n-butyraldehyde, continue to cool down to 20°C, add 30g of hydrochloric acid (the concentration of hydrochloric acid is 10wt%), keep Keep the temperature unchanged for 2 hours; the emulsifier is sodium diisooctyl sulfonate;

[0038] 3) Raise the temperature to 75°C at a uniform speed, keep it warm for 1 hour, add sodium hydroxide to adjust the pH to 4.5, maintain it for 2 hours...

Embodiment 3

[0040] A nano-silica modified PVB material is prepared by introducing nano-silica into the PVB material in situ, and its preparation method comprises the following steps:

[0041] 1) Weigh 30g of polyvinyl alcohol and 250g of deionized water, add 0.1g of antioxidant under the action of mechanical stirring, raise the temperature to 100°C and keep it for 1 hour to ensure that the PVA is completely dissolved; in this example, in other examples, Antioxidant can also choose β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, in other embodiments, you can also choose bis(3,5-di-tert-butyl One of the pentaerythritol diphosphites;

[0042] 2) Cool down to 30°C, add 0.05g of emulsifier, add 1g of nano-silicon dioxide, homogeneously emulsify for 1.2h, add 20g of n-butyraldehyde, continue to cool down to 15°C, add 25g of hydrochloric acid (the concentration of hydrochloric acid is 7wt%), keep The temperature remains unchanged for 1.5h; in this embodiment, the emulsifier is sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com