Industrial waste disposal and resource utilization equipment

A technology for recycling industrial waste, which is applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve problems such as air pollution and heat waste, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0027] It can be understood that the pipelines involved in the present invention are provided with control valves, and the control valves can be any of gate valves, globe valves, diaphragm valves, ball valves, check valves, pressure reducing valves, steam traps and butterfly valves. One or more, those skilled in the art can select the type and quantity of control valves on a certain pipeline according to actual needs.

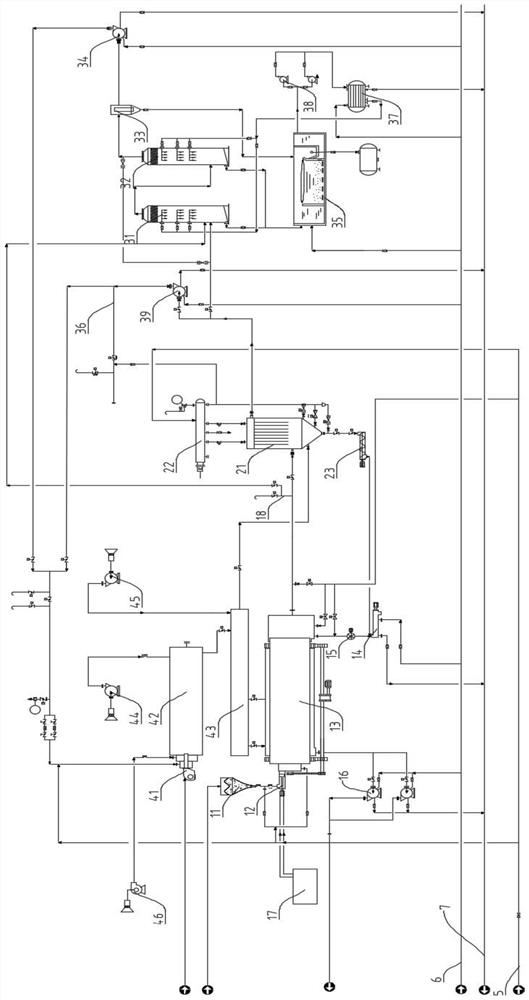

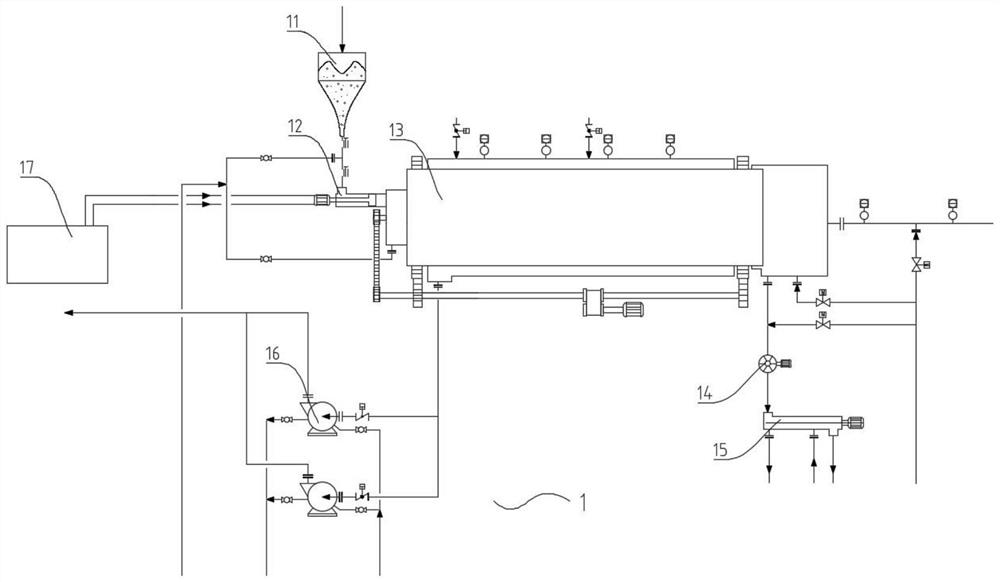

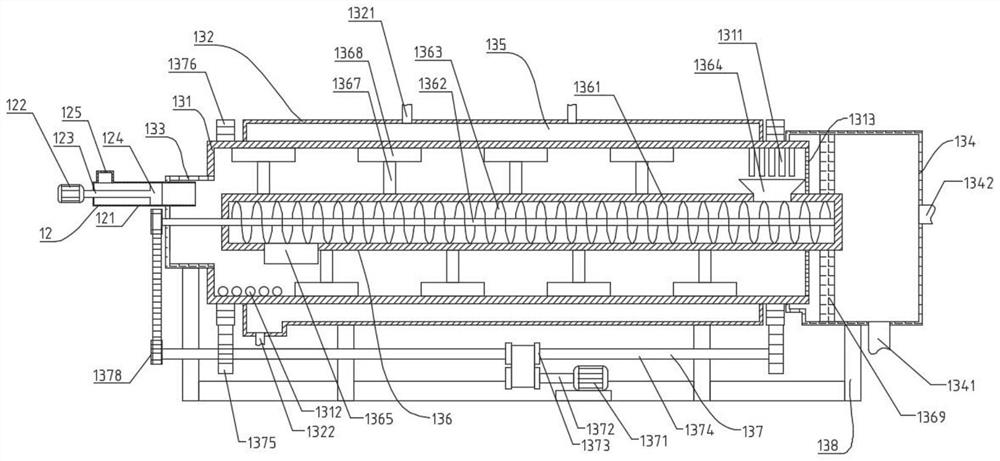

[0028] Such as Figure 1-7As shown, the industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com