Pyrogenic treatment method for hazardous waste incineration ash

A technology for incineration of ash and slag and fire treatment, which is applied in combustion methods, chemical instruments and methods, incinerators, etc., can solve the problems of difficult transportation, limited wide application, low metal recovery rate, etc., to avoid secondary pollution, The effect of reducing dust pollution and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

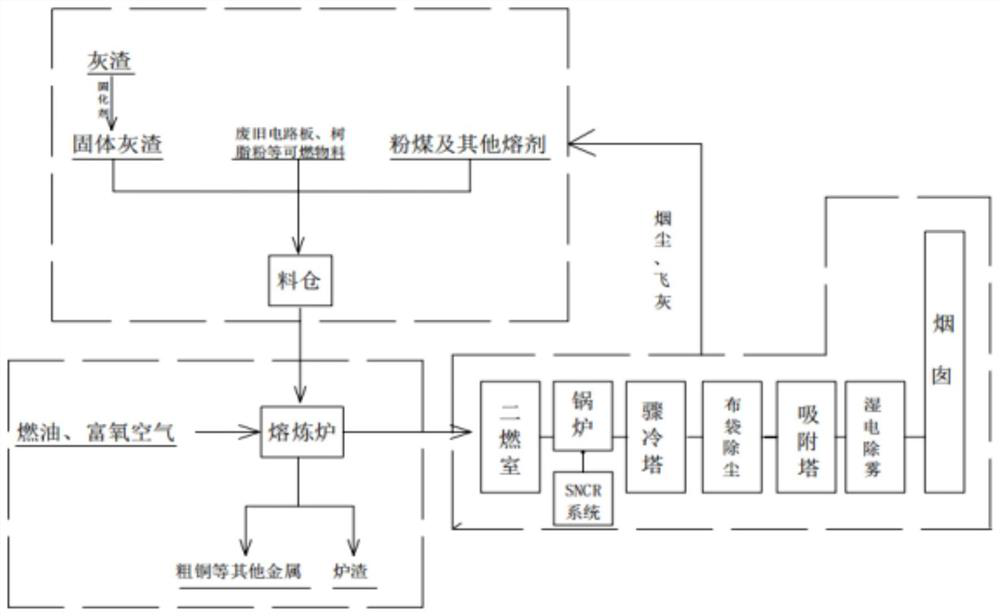

Image

Examples

Embodiment 1

[0044] Reaction raw materials: Hazardous waste incineration slag and flue gas system smoke and fly ash, waste circuit boards.

[0045] The reaction flux is quartz stone, limestone, pellets, pulverized coal and cement.

[0046] The oxygen-enriched air content in the spray gun is 30%, and the fuel sources are diesel oil blown into the spray gun, pulverized coal supplied by the raw material system, and waste circuit boards.

[0047] The solidified ash and waste circuit boards are mixed at a ratio of 1:1, and then transported by a belt into the top-blown melting pool melting furnace for melting. During the melting process, quartz stone, limestone and pulverized coal are added. The temperature of the melting process is controlled at 1100°C. It is CaO-SiO2-A12O3-FeO quaternary slag type, the iron-silicon ratio is controlled at 1.0-1.5 during the top blowing smelting process, and the oxygen-material ratio is 0.35.

[0048] The flue gas produced by smelting enters the flue gas system...

Embodiment 2

[0051] Reaction raw materials: Hazardous waste incineration slag and flue gas system smoke and fly ash, resin powder.

[0052] The reaction flux is quartz stone, limestone, pellets, pulverized coal and cement.

[0053] The oxygen-enriched air content in the spray gun is 65%, and the fuel source is diesel oil blown into the spray gun, pulverized coal and resin powder supplied by the raw material system.

[0054] After the solidified ash and resin powder are mixed according to the ratio of 1:2, they are transported by a belt into the top-blown melting pool melting furnace for melting. During the melting process, quartz stone, limestone and pulverized coal are added. The temperature of the melting process is controlled at 1000°C. CaO-SiO2-A12O3-FeO quaternary slag type, the iron-silicon ratio is controlled at 1.0-1.5 during the top blowing smelting process, and the smelting oxygen-material ratio is 0.5.

[0055] The flue gas produced by smelting enters the flue gas system and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com