Outburst coal seam shield pressure relief in-hole drilling tool and out-hole sealing system thereof

A technology of protruding coal seam and closed system, which is applied in the direction of drilling tools, drill bits, drill pipes, etc., to achieve good slag discharge effect, smooth fluid slag discharge, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

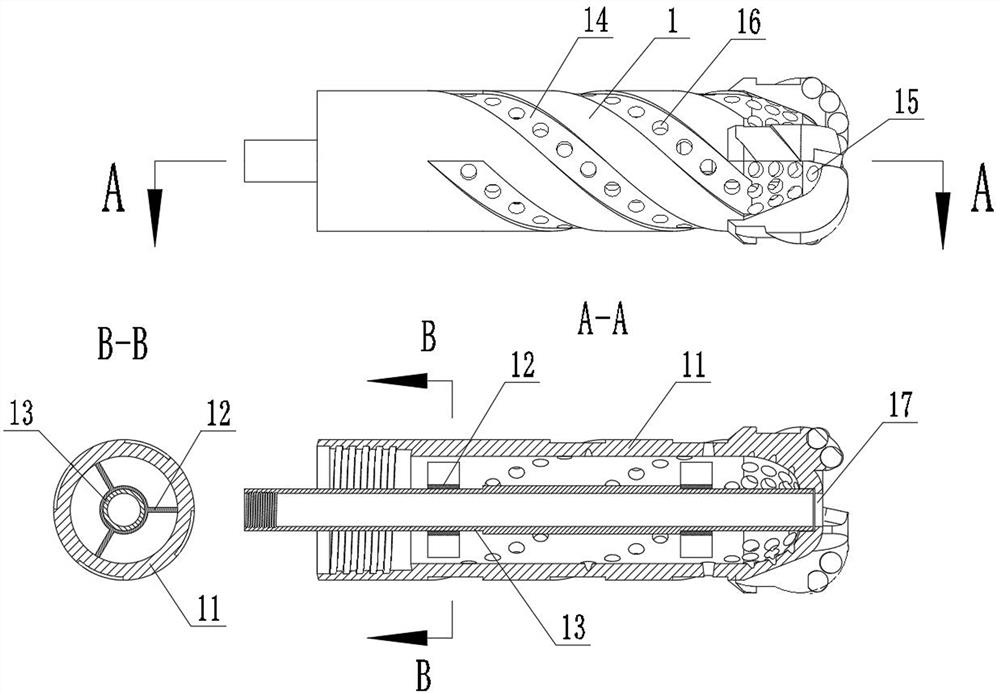

[0030] figure 1 Schematic diagram of the structure of the sieve drill bit for highlighting the pressure relief hole of the coal seam shield. The sieve drill bit 1 includes a drill bit shell 11, a support frame 12 and a rotatable flow supply nipple 13. The support frame 12 is coaxial with the drill bit shell 11. Fixed, the rotatable flow supply nipple 13 passes through the center hole of the support frame 12 and is arranged coaxially with the drill bit housing 11, and the rotating flow supply nipple 13 can freely rotate in the support frame 12; the drill bit housing 11 is provided with a spiral groove 14. Axial sieve hole 15, radial sieve hole 16, outflow hole 17, the tail of the drill bit housing 11 is provided with a female button for connecting with the sieve hole drill pipe; one end of the rotatable flow supply joint 13 leads to The outlet hole 17 at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com